Co-mining tunneling method of seam roadway gas

A coal mining method and roadway technology, which is applied in ground mining, mining equipment, earth drilling and mining, etc., can solve problems such as climate warming, low utilization rate, and damage to the ecological environment, and achieve prevention of gas explosions, extended service life, and corrosion Mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

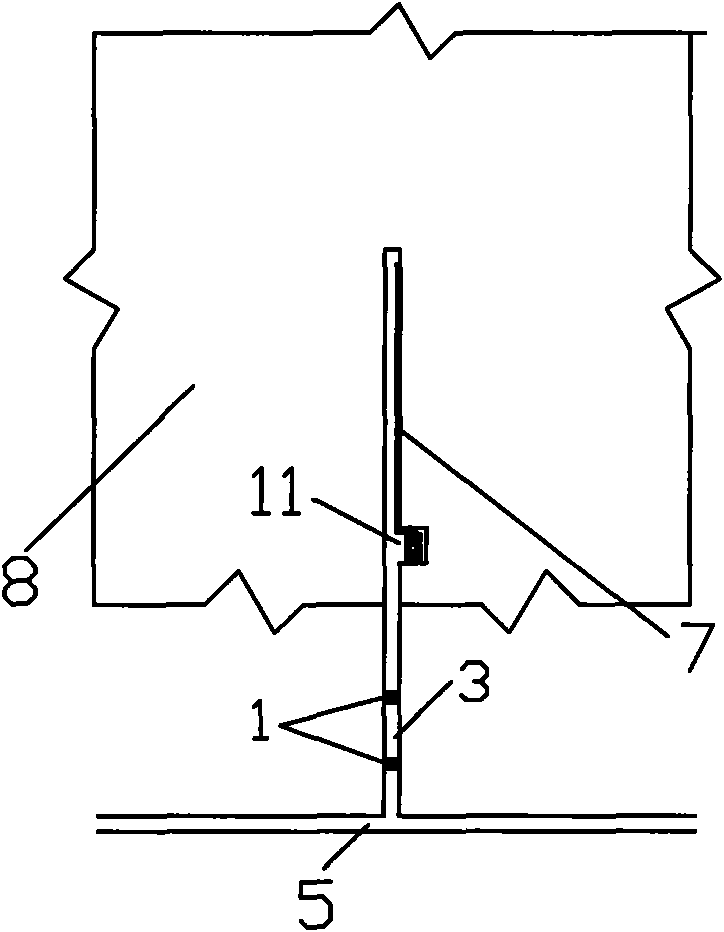

[0022] Embodiment one, figure 1 image 3 As shown in Fig. 4 and Fig. 5, when the coal seam has no outburst danger identified by the outburst hazard, the steps of the coal seam tunnel gas co-mining excavation method are as follows:

[0023] a. figure 1 As shown, after the tunneling of the uphill roadway 5 is completed, the coal seam roadway 7 is driven into the coal seam 8 from the uphill roadway 5;

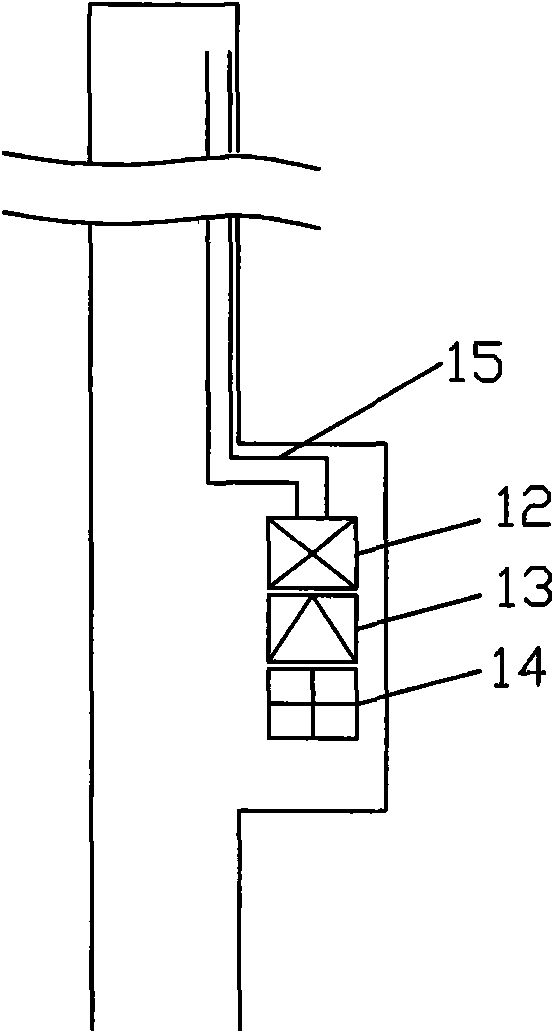

[0024] b. Construct an air-conditioning cavern 11 inside the coal seam roadway 7, and install a local ventilator 12, ventilation duct 15, air conditioner 13 and dust removal equipment 14 in sequence in the air-conditioning cavern 11;

[0025] c. Install two airtight doors 1 at intervals at the entrance of the coal seam roadway 7, which can pass through mine cars and pedestrians, so that a closed space is formed in the coal mining area. The carrying capacity of the two airtight doors 1 is required to be no less than 1MPa.

[0026] d. Lay a gas drainage pipeline inside the coal s...

Embodiment 2

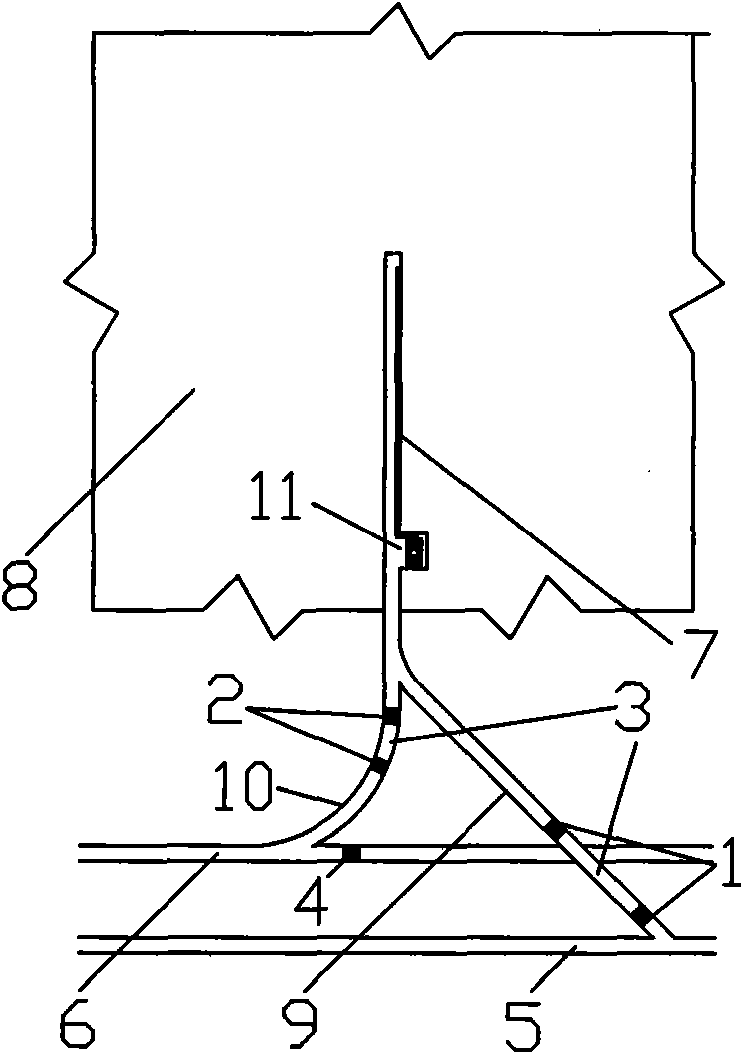

[0032] Embodiment two, figure 2 image 3 As shown in Fig. 4 and Fig. 5, when the coal seam is identified as outburst risk, the steps of the coal seam roadway gas co-extraction tunneling method are as follows:

[0033] a. After the tunneling of the uphill roadway 5 is completed, a return airway 6 is excavated, and the transportation roadway 9 and the coal seam roadway 7 are sequentially excavated from the uphill roadway 5 to the coal seam 8; The arc-shaped pressure relief tunnel 10 is used to reduce the resistance of wind flow from the section return air tunnel 14 or the section transport tunnel 7 to the arc-shaped pressure relief tunnel 10 . Under the condition of not affecting the ventilation and normal use, the airtight door 4 of the mining area can be installed inside the air return roadway 6 and on the windward side of the intersection of the pressure relief roadway 10 and the air return roadway 6, so as to prevent the possibility of protruding high-pressure gas. The en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com