Preparation method of inhibitor for spontaneous combustion of coal based on magnesium ion compound

A compound, magnesium ion technology, applied in mining equipment, earthwork drilling, safety devices, etc., can solve the problems of low stability, generation of combustible or toxic gas, easy oxidation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

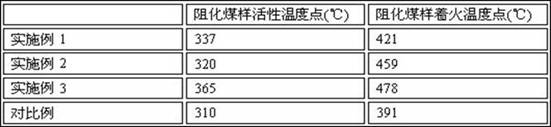

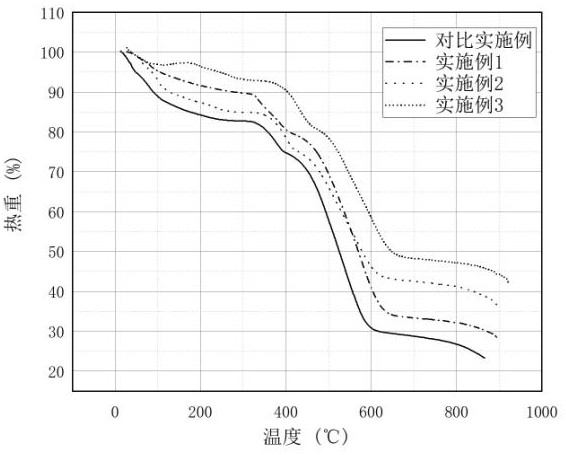

Embodiment 1

[0028] 22 parts by mass of MgCl that will be weighed 2 ·6H 2 Mix O powder with 50 parts by mass of water, stir for 5~10min, add 6 parts by mass of NaOH powder after completely dissolving, stir for 5min with a glass rod, add 0.37 parts by mass of vinyltriethoxysilane as a dispersant, and stir for 10min with a glass rod Allow it to fully react to obtain a mixed solution; place it in a dark place and seal it for 2 hours, filter, dry, and vacuum dry (85°C, 5 hours) to obtain a coal spontaneous combustion retardant based on a magnesium ion compound.

Embodiment 2

[0030] 30 parts by mass of MgCl after drying 2 ·6H 2 Mix O powder with 50 parts by mass of water, stir for 5 to 10 minutes to completely dissolve, add 8 parts by mass of NaOH powder, stir with a glass rod for 5 minutes, add 0.51 parts by mass of vinyltrimethoxysilane as a dispersant, and continue stirring for 15 minutes to fully react The mixed solution was obtained; placed in a dark place and sealed for 3 hours, filtered, dried, and vacuum-dried (90°C, 3 hours) to obtain a coal spontaneous combustion retardant based on magnesium ion compounds.

Embodiment 3

[0032] 26 parts by mass of MgCl after drying 2 ·6H 2 Mix O powder with 44 parts by mass of water, add 7 parts by mass of NaOH powder after completely dissolving, stir with a glass rod for 5 minutes, add 0.44 parts by mass of vinyl tris(β-methoxyethoxy)silane as a dispersant, and stir with a glass rod Allow it to fully react for 20 minutes to obtain a mixed solution; place it in a dark place and seal it for 2 hours, filter, dry, and vacuum dry (100°C, 4 hours) to obtain a coal spontaneous combustion inhibitor based on a magnesium ion compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com