Foamed gel for preventing and controlling spontaneous combustion of coal in goaf and application

A technology of gel foam and coal spontaneous combustion, which is applied in dust prevention, mining equipment, earthwork drilling and mining, etc., can solve the problems of poor oxygen barrier capacity of leftover coal plugging, poor water retention capacity of two-phase foam, and massive dehydration, etc., and achieves improved Stability and water retention performance, suppression of coal spontaneous combustion, good water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

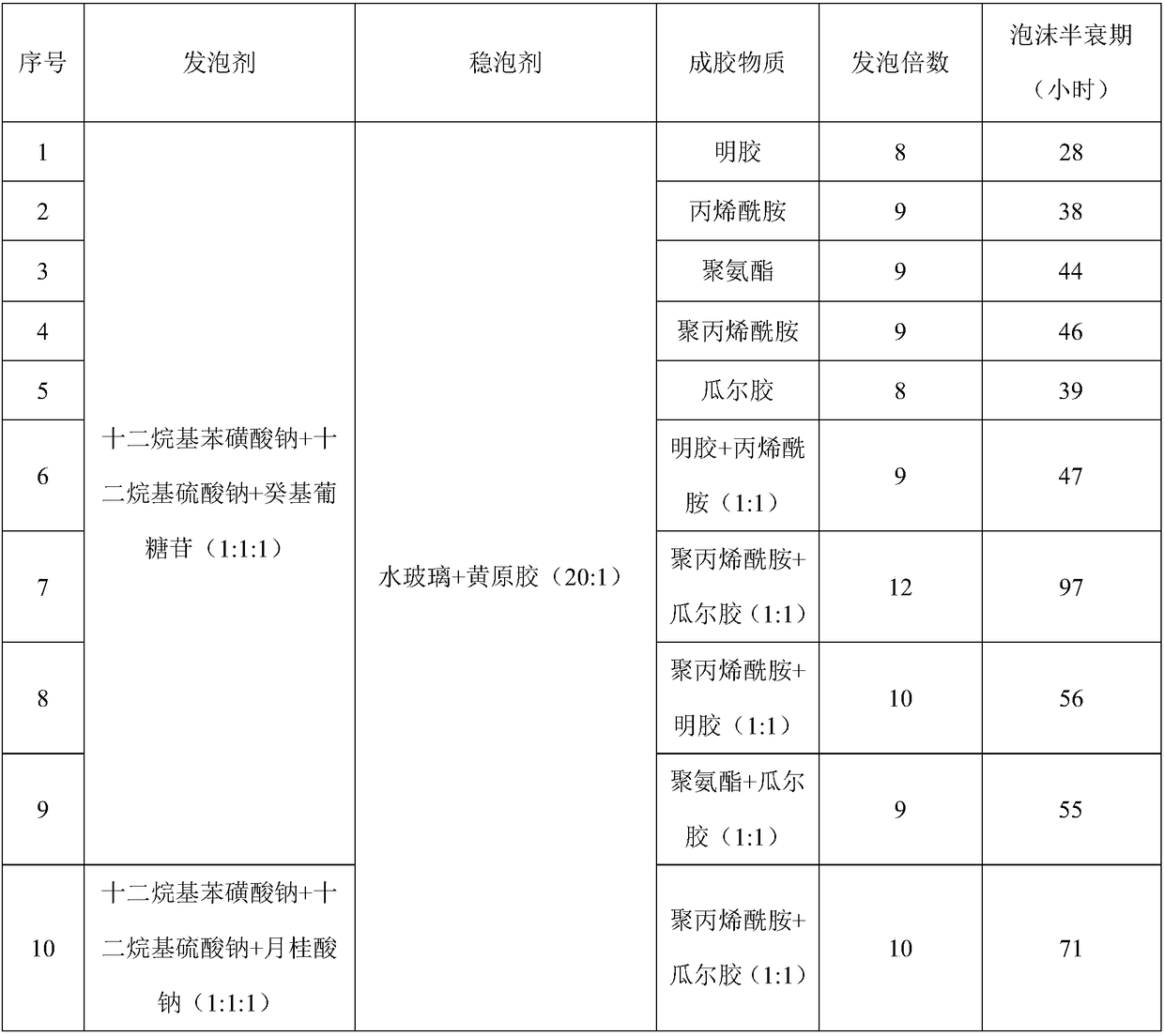

[0029] Determine the mass percent of the gel foam base liquid to be 50 g, wherein the mass percent of foaming agent is 0.4 percent, the mass percent of foam stabilizer is 2 percent, the mass percent of gel-forming substance is 0.6 percent, and the rest is water. After adding foaming agent and foam stabilizer into water at the same time, use the hole plate hitting method for initial foaming, and stop foaming when the foam reaches 80% of the maximum foaming volume; then, add the gel-forming substance into the initiated foam, The final foaming is carried out by perforated disk blowing method.

[0030] After placing the coal sample soaked in gel foam and the coal sample soaked in water under the same conditions for 7 days, the temperature program was used to simulate the coal spontaneous combustion process, and the cross point temperature was tested. It was found that the coal sample treated with gel foam, the cross The point temperature is about 20°C higher than the intersection ...

Embodiment 2

[0032] Determine the mass percent of the gel foam base liquid to be 50 g, wherein the mass percent of foaming agent is 0.5 percent, the mass percent of foam stabilizer is 3 percent, the mass percent of gel-forming substance is 0.7 percent, and the rest is water. After adding foaming agent and foam stabilizer into water at the same time, use hole plate hitting method for initial foaming, and stop foaming until 80% of the maximum foaming volume; The final foaming is carried out by perforated disk blowing method.

[0033] Using the same method as in Example 1, the resistance rate of the gel foam at 100° C. was calculated to be Eco=68%, indicating that the gel foam of the present invention has a good effect of preventing coal spontaneous combustion.

Embodiment 3

[0035] Determine the quality of gel foam base liquid to be 50g, wherein the mass percentage of foaming agent is 0.6%, the mass percentage of foam stabilizer is 2.5%, the mass percentage of gel-forming substance is 0.8%, and the rest is water. After adding foaming agent and foam stabilizer into water at the same time, use hole plate hitting method for initial foaming, and stop foaming until 80% of the maximum foaming volume; The final foaming is carried out by perforated disk blowing method.

[0036] Using the same method as in Example 1, the resistance rate Eco=69% of the gel foam at 100° C. was calculated, indicating that the gel foam of the present invention has a good effect of preventing coal spontaneous combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com