Production process of polymer self-adhesive waterproof membrane

A self-adhesive waterproof membrane and production process technology, applied in the direction of layered products, adhesives, adhesive types, etc. Effects of tack and peel strength, simplified dosing system, cost and energy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

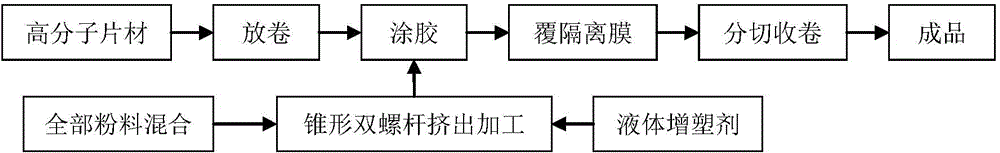

[0035] like figure 1 As shown, the production process of the polymer self-adhesive waterproof membrane of the present embodiment comprises the following steps:

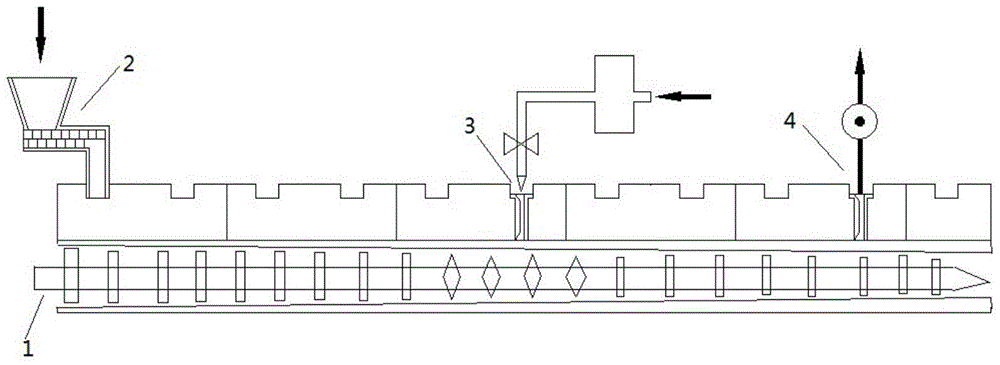

[0036] Step 1: Mix the thermoplastic rubber, tackifying resin, filler and antioxidant powder evenly, and add them to the feed hopper 2 of the conical twin-screw extruder;

[0037] Step 2: The conical twin-screw extruder is running, and plasticizer is added through the feeding port 3 arranged in the middle section of the conical twin-screw extruder; the middle section of the screw 1 of the conical twin-screw extruder is provided with a reverse mixing thread, The plasticizer and the powder in step 1 are mixed through a conical twin-screw extruder, and the plasticizer is mixed evenly with the powder in step 1; the middle section of screw 1 is 0.25-0.75L (L is the length of the screw) There is a reverse mixing thread at the center, the length of the reverse mixing thread is 0.2-0.4L, the reverse mixing thread ensures tha...

Embodiment 2

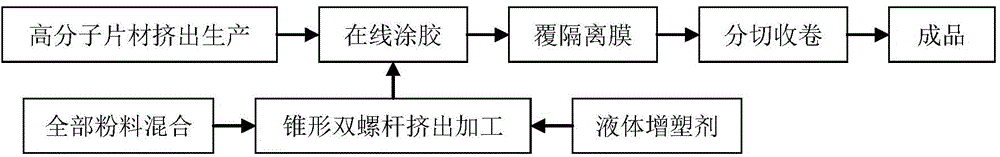

[0045] like figure 2 As shown, the present embodiment is the same as embodiment 1 except the following differences:

[0046] Step 3: Use a vacuum exhaust device to perform vacuum exhaust through the vacuum exhaust hole 4 arranged at 0.75-0.85L of the conical twin-screw extruder. The vacuum degree is 0.08MPa;

[0047] Step 4: The hot-melt pressure-sensitive adhesive produced in step 3 passes through the melt metering pump and glue coating die on the head of the conical twin-screw extruder, and the polymer sheet is passed through the sheet extruder and three-roll calendering The production is arranged directly under the coating die, and the hot-melt pressure-sensitive adhesive flows out from the coating die to coat the polymer sheet, and the temperature of the coating die is 180°C.

[0048] The ratio of parts by weight of thermoplastic rubber, tackifying resin, filler, antioxidant and plasticizer is: thermoplastic rubber: 4.5 parts; tackifying resin: 4 parts; filler: 0.4 part;...

Embodiment 3

[0052] This embodiment is the same as embodiment 1 except the following differences:

[0053] Thermoplastic rubber: 2 parts; tackifying resin: 7 parts; filler: 0.5 part; antioxidant: 0.05 part; plasticizer: 1 part;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com