Ionic current based spark ignition engine preignition detection control device

A spark-ignition, ion current technology, applied in engine control, combustion engine, machine/engine, etc., can solve problems such as discontinuity, poor accuracy, engine damage, etc., to reduce damage, avoid super knock, and inhibit spontaneous combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

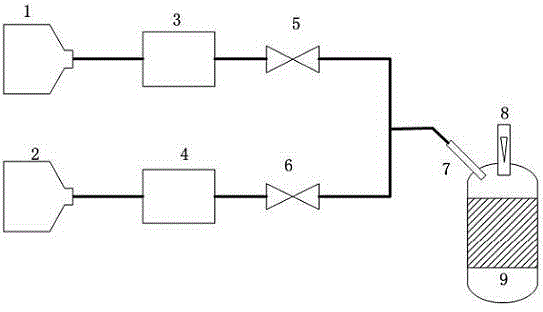

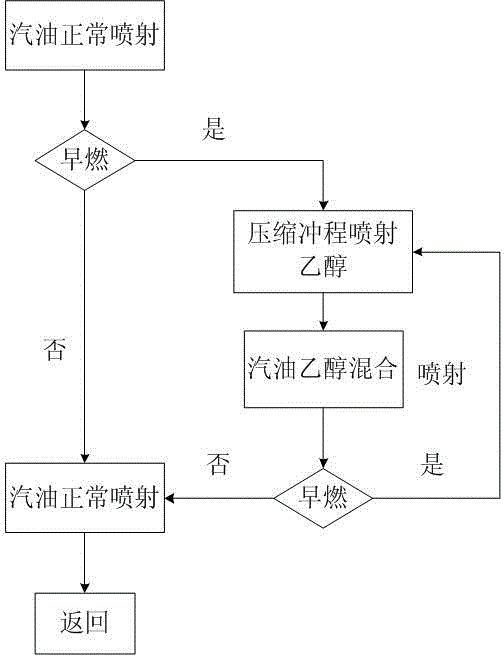

[0020] Such as figure 1 and figure 2 As shown, the present invention provides a spark ignition type engine pre-ignition detection and control device based on ion current, comprising ethanol low-pressure oil circuit 1, ethanol high-pressure common rail pipe 3, control ethanol solenoid valve 5, gasoline low-pressure oil circuit 2, gasoline High-pressure common rail pipe 4, control gasoline solenoid valve 6, mixed fuel injector 7 and ion current detection device 8; ion current detection device 8 detects that before spark ignition, spontaneous combustion occurs in the combustion chamber, and controls ethanol solenoid valve 5 during the compression stroke Turn on the injection of a certain amount of ethanol to lower the temperature in the combustion chamber, suppress pre-ignition, and in the subsequent cycle, control the ethanol solenoid valve 5 and gasoline solenoid valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com