Composite microcapsule stopping agent for preventing coal spontaneous combustion and preparation method of composite microcapsule stopping agent

A technology of composite microcapsules and coal spontaneous combustion, which is applied in dust prevention, mining equipment, earthwork drilling, etc., can solve the problems of uneven distribution of inhibitors, poor inhibitory effect, narrow coverage, etc., and achieves wide coverage, High resistance rate, no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

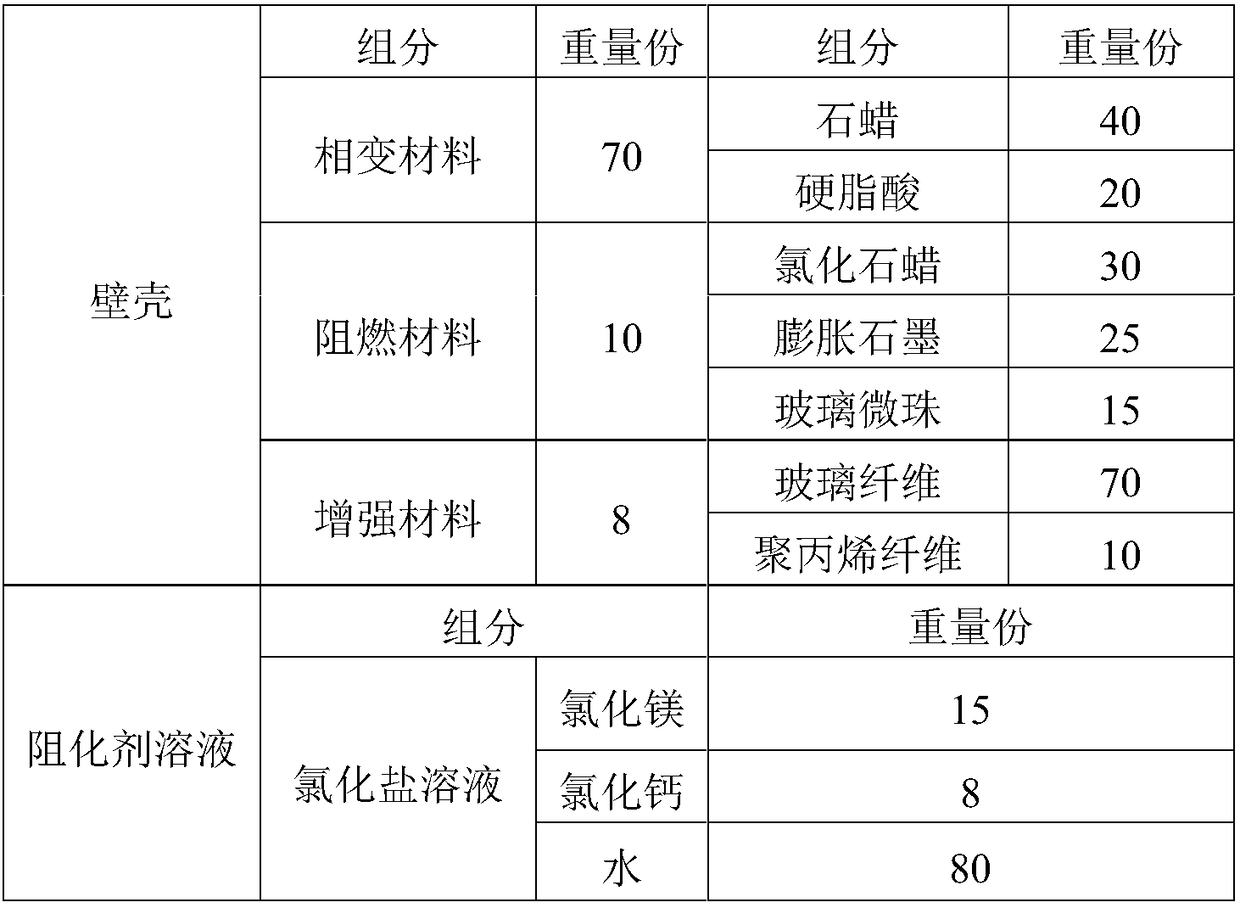

[0026] A composite microcapsule inhibitor for preventing coal spontaneous combustion, comprising a shell and an inhibitor solution sealed in the shell, the component content of the shell and the inhibitor solution: see Table 1.

[0027] Each component weight part of table 1 embodiment one

[0028]

[0029] The preparation method of the composite microcapsule inhibitor for the above-mentioned prevention and treatment of coal spontaneous combustion comprises the following steps:

[0030] (1) Preparation of inhibitor solution: prepare and measure magnesium chloride solution and calcium chloride solution respectively, prepare the mixed solution of magnesium chloride and calcium chloride, stand-by after preparation;

[0031] (2) Preparation of composite phase change mixture: measure phase change material, flame retardant material and reinforcing material and add them to the mixer to mix evenly to obtain composite phase change mixture, then heat the composite phase change mixture...

Embodiment 2

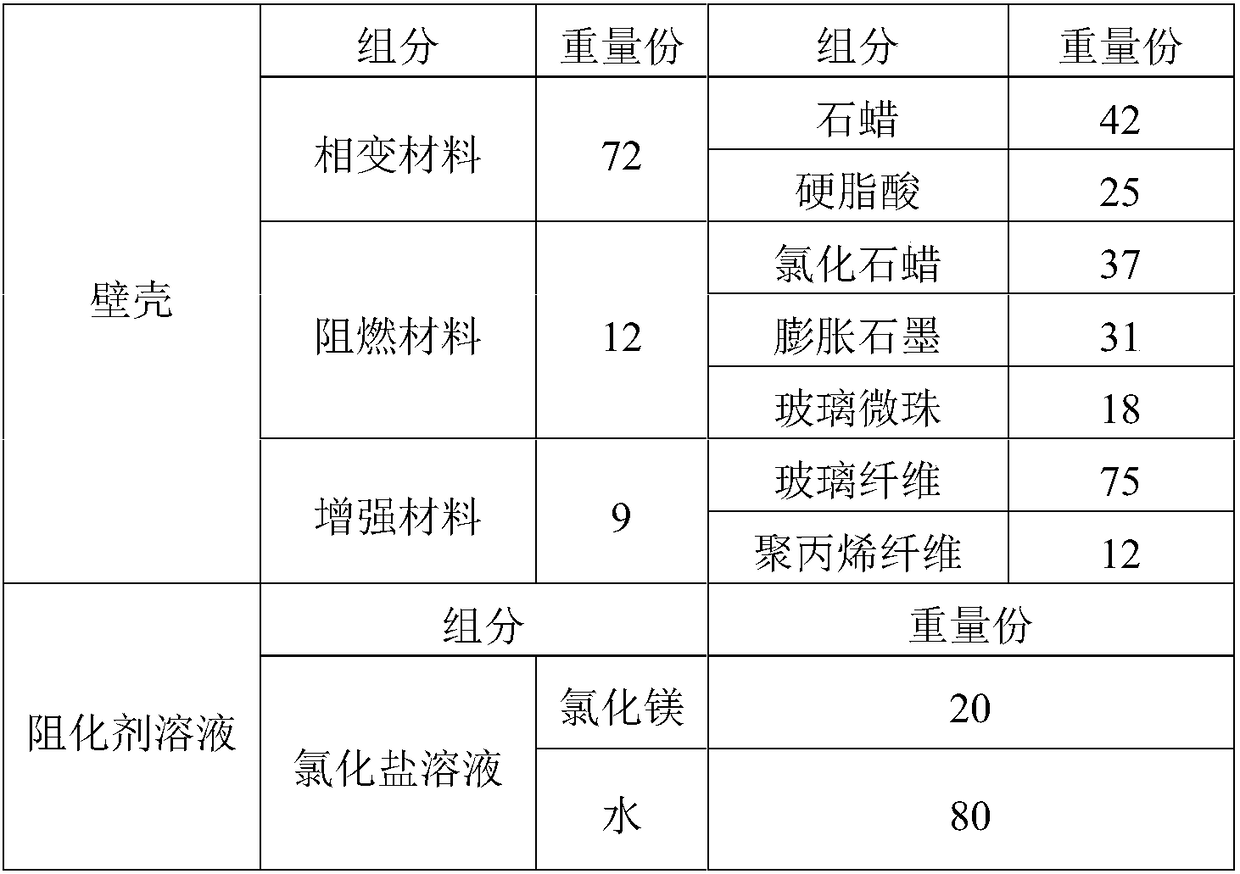

[0037] A composite microcapsule inhibitor for preventing coal spontaneous combustion, comprising a shell and an inhibitor solution sealed in the shell, the component content of the shell and the inhibitor solution: see Table 2.

[0038] Each component weight part of table 2 embodiment two

[0039]

[0040] The preparation method of the composite microcapsule inhibitor for the above-mentioned prevention and treatment of coal spontaneous combustion comprises the following steps:

[0041] (1) Preparation of inhibitor solution: magnesium chloride solution is prepared after magnesium chloride and water are measured, and stand-by after preparation is completed;

[0042] (2) Preparation of composite phase change mixture: measure phase change material, flame retardant material and reinforcing material and add them to the mixer to mix evenly to obtain composite phase change mixture, then heat the composite phase change mixture to 65-70°C Constant temperature storage;

[0043] (3) ...

Embodiment 3

[0048] A composite microcapsule inhibitor for preventing coal spontaneous combustion, comprising a shell and an inhibitor solution sealed in the shell, the component content of the shell and the inhibitor solution: see Table 3.

[0049] Each component weight part of table 3 embodiment three

[0050]

[0051] The preparation method of the composite microcapsule inhibitor for the above-mentioned prevention and treatment of coal spontaneous combustion comprises the following steps:

[0052] (1) Preparation of inhibitor solution: take triethyl (tetradecyl) phosphine chloride salt ionic liquid for stand-by;

[0053] (2) Preparation of composite phase change mixture: measure the phase change material, flame retardant material and reinforcing material, add them to the mixer and mix them evenly to obtain the composite phase change material emulsion, and then heat the composite phase change material emulsion to 65-70°C Constant temperature storage;

[0054] (3) uniformly mix the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com