Coal pile temperature measuring and cooling grouting device and system

A technology of grouting device and coal pile, which is applied to measuring devices, electrical devices, thermometers, etc., can solve the problems of uneven water volume, easy loss, and coal washing away, so as to prevent and control spontaneous combustion, inhibit oxidation and spontaneous combustion, The effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

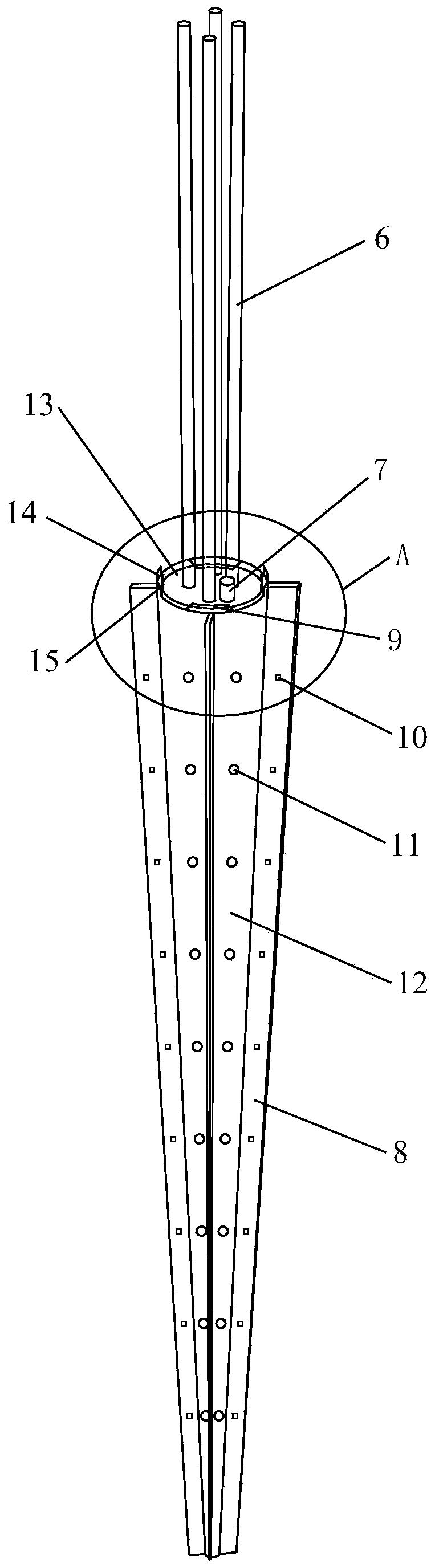

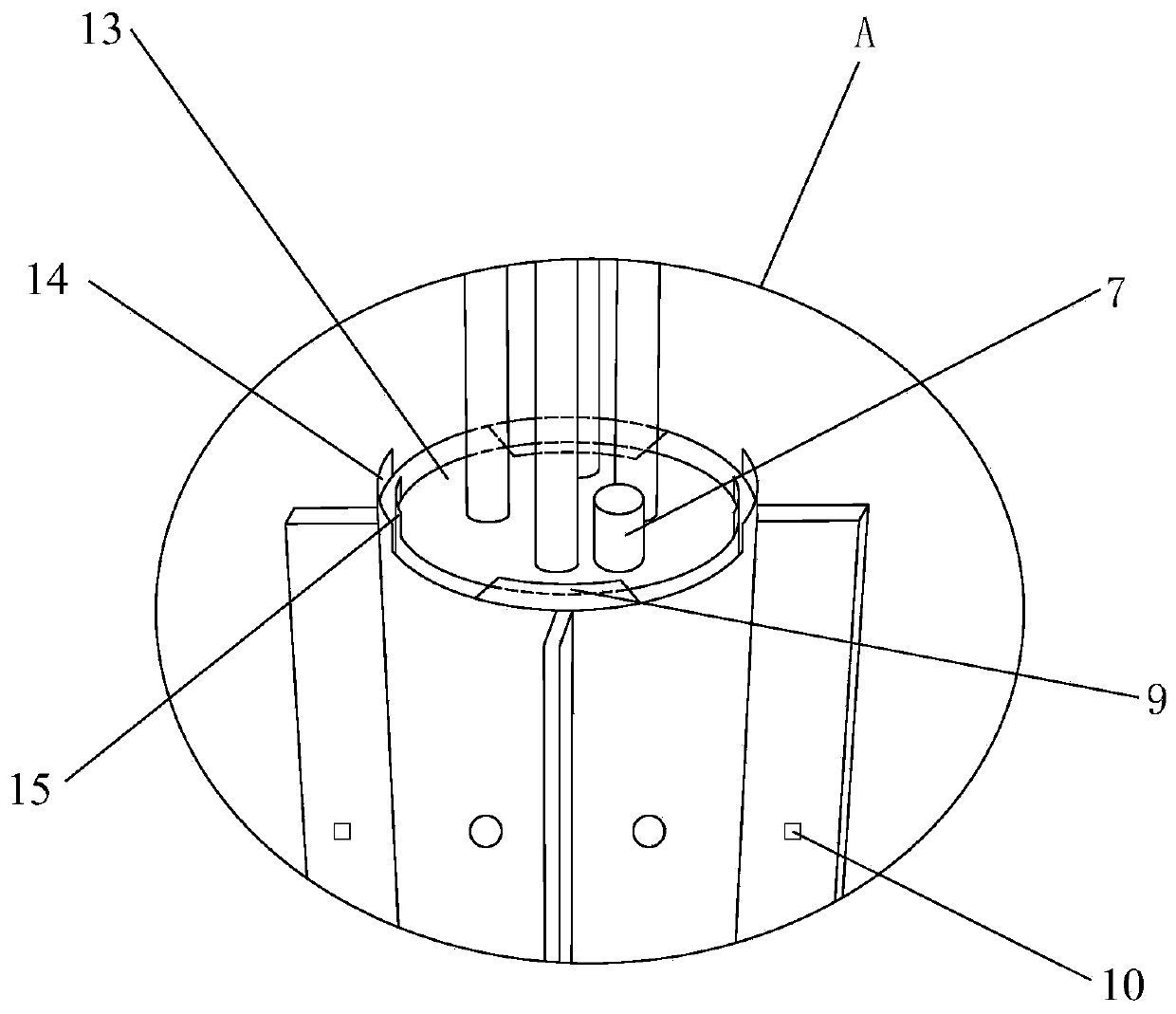

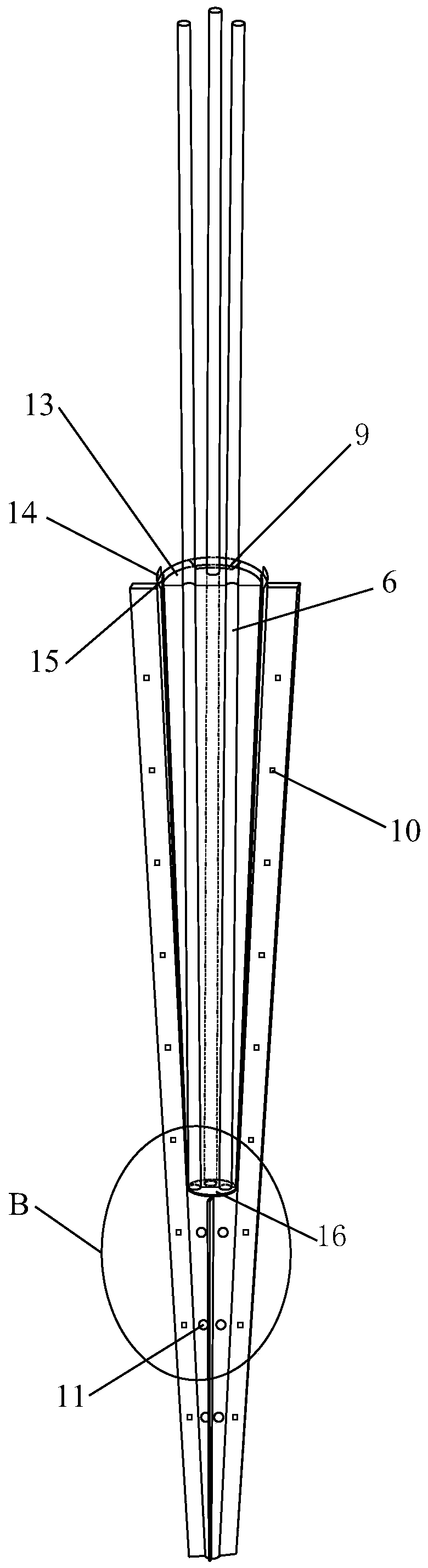

[0052] Such as Figure 1 to Figure 12 As shown, a coal pile temperature measuring and cooling grouting device includes an outer rounded platform body 12, an inner layer rounded platform body 18 and a self-moving heat pipe 6, and the outer layer rounded platform body 12 and the inner layer rounded platform body 18 All are hollow structures, the inner layer rounded platform body 18 is arranged in the outer layer rounded platform body 12, the front and rear sides of the upper port inner wall of the outer layer rounded platform body 12 are provided with bayonet 9, the inner layer rounded platform body The body 18 is connected to the outer rounded platform body 12 through the bayonet 9 and can rotate relative to the outer layer rounded platform body 12. The top of the outer layer rounded platform body 12 is an open structure, and the bottom of the outer layer rounded platform body 12 is set There is an outer layer conical body bottom plate 20, the top of the inner layer rounded fru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com