Reconstruction method for water-proof shell

A water-proof and water-layer technology, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems such as the inability to guarantee the safety of mine production, the inability of efficient and continuous mining of ore deposits, and the increase of the burden of mine drainage, so as to avoid surface collapse. , The effect of reducing the amount of drying and preventing the reduction of the water level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

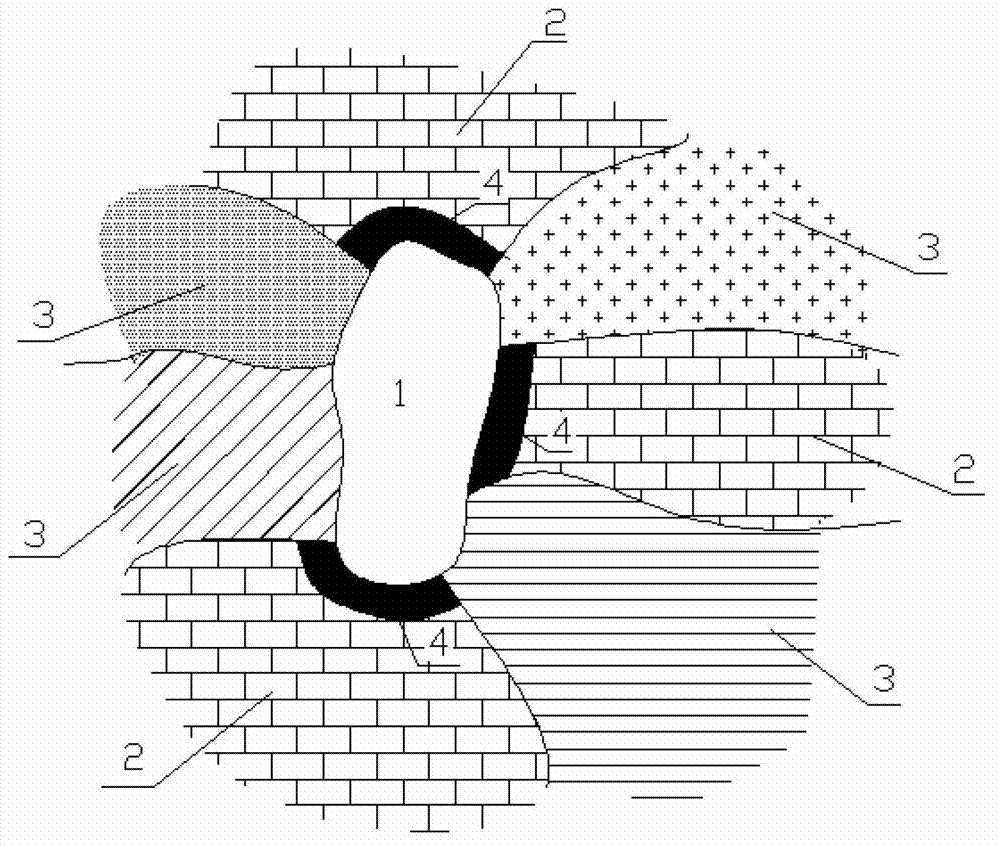

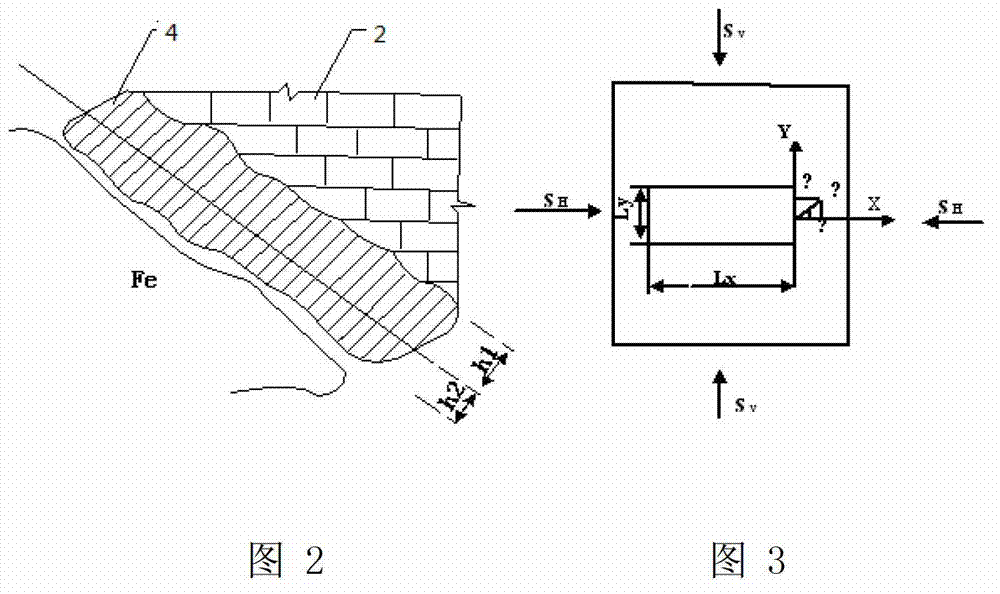

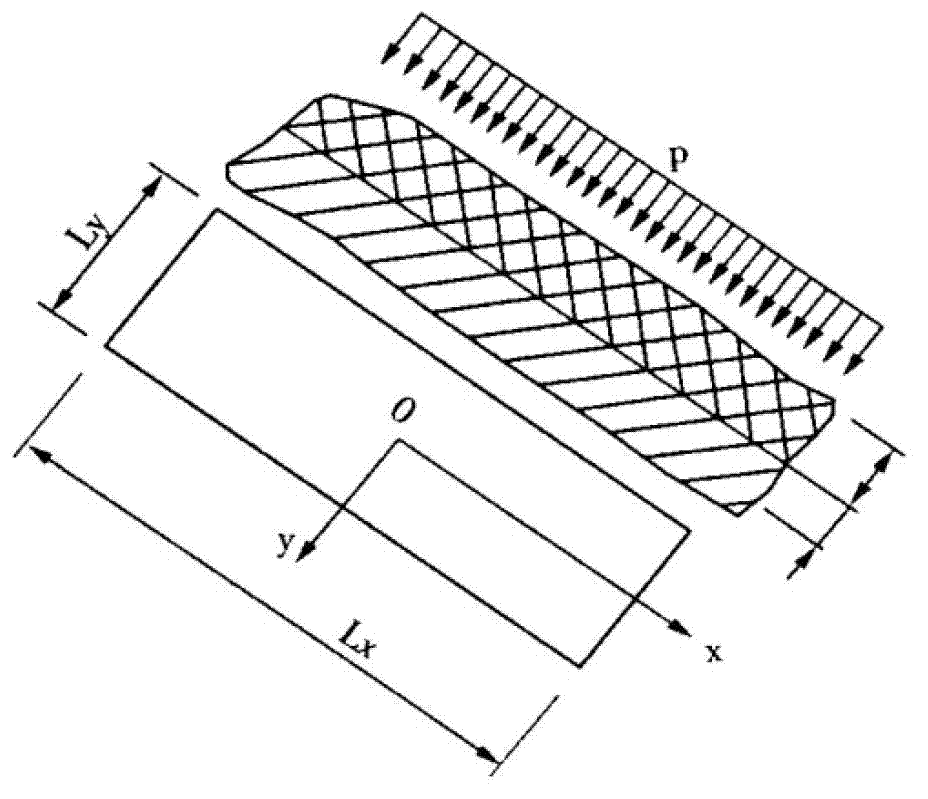

[0029] The specific use case of water-proof shell reconstruction proposed by the present invention is an example of the case where the roof rock mass is an aquifer:

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , in the figure: 1 is the ore body; 2 is the aquifer; 3 is the aquifer rock or weakly permeable rock; 4 is the water-resisting shell; 5 is the karst cave or fissure in the aquifer; Injection chamber; 8 is a grouting hole; the water-proof shell reconstruction method provided by the invention is: collect geological data and carry out corresponding geological survey, determine the distribution of aquifers around the deposit and various stresses and hydrological parameters of surrounding rocks; The shell includes an invalid thickness h 2 and effective thickness h 1 , according to the mining design parameters to establish a mechanical model, combined with the boundary conditions, Mohr-Calomb failure criterion and fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com