Reflection and heat insulation paint for buildings

A reflective thermal insulation coating, construction technology, applied in reflective/signal coatings, antifouling/underwater coatings, coatings, etc., can solve the problem of brittleness and brittleness of functional fillers, low production process efficiency, difficult equipment cleaning, etc. The problem is to improve the thermal insulation, the production process is simple and efficient, and the thermal insulation effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

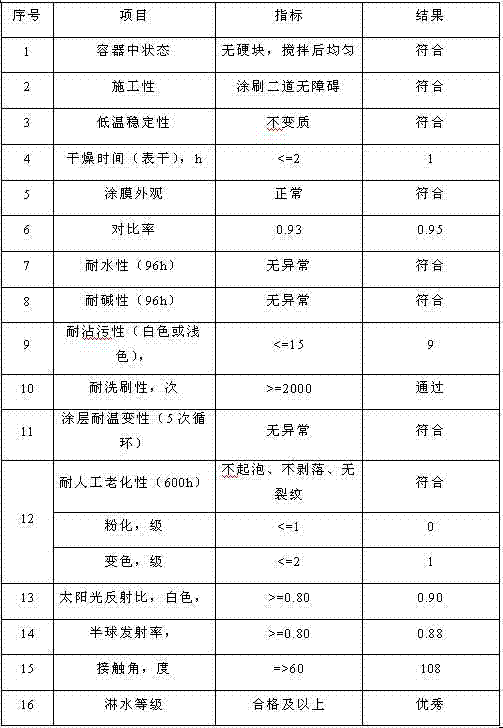

Embodiment 1

[0049] A reflective heat-insulating coating for buildings, in parts by weight, comprising the following components and a preparation method:

[0050] Add 8.5 parts of water and 0.04 parts of the first thickener (BERMOCOLL EHM300, which is a composite non-ionic water-soluble cellulose ether) into the dispersing tank, start the dispersing machine to adjust the speed to about 800 rpm, and then add 0.45 part of DA dispersant, 0.1 part of PE100 wetting agent, 0.2 part of first defoamer (SPA202), 0.3 part of second defoamer (DFC17), 0.05 part of multifunctional additive (AMP95), 0.05 part of preservative ( DOA2w), 0.005 parts of antifungal agent (H981), stir evenly, continue to add 15 parts of titanium dioxide, 22.5 parts of composite heat insulation powder, 2.5 parts of 800 mesh sericite powder, 4 parts of 800 mesh ground calcium carbonate;

[0051] Pre-emulsify 1 part of propylene glycol, 1.25 parts of film-forming aid (CS-12), 0.01 part of emulsifier (T-80), and 1 part of water i...

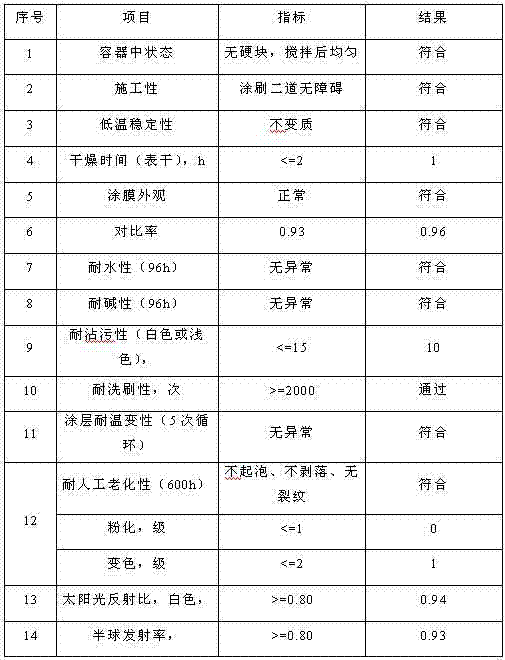

Embodiment 2

[0078] A reflective heat-insulating coating for buildings, in parts by weight, comprising the following components and a preparation method:

[0079] Add 17.5 parts of water and 0.06 parts of the first thickener (BERMOCOLL EHM300, which is a composite non-ionic water-soluble cellulose ether) into the dispersing tank, start the dispersing machine to adjust the speed to about 800 rpm, and then add 0.5 part of DA dispersant, 0.15 part of PE100 wetting agent, 0.2 part of first defoamer (SPA202), 0.2 part of second defoamer (DFC17), 0.15 part of multifunctional additive (AMP95), 0.1 part of preservative ( DOA2w), 0.25 parts of antifungal agent (H981), stir evenly, continue to add 19 parts of titanium dioxide, 15 parts of composite heat insulation powder, 2.5 parts of 800 mesh sericite powder, 4 parts of 800 mesh ground calcium carbonate;

[0080] Pre-emulsify 1.5 parts of ethylene glycol, 1.7 parts of film-forming aid (CS-12), 0.015 parts of emulsifier (T-80), and 1.825 parts of wa...

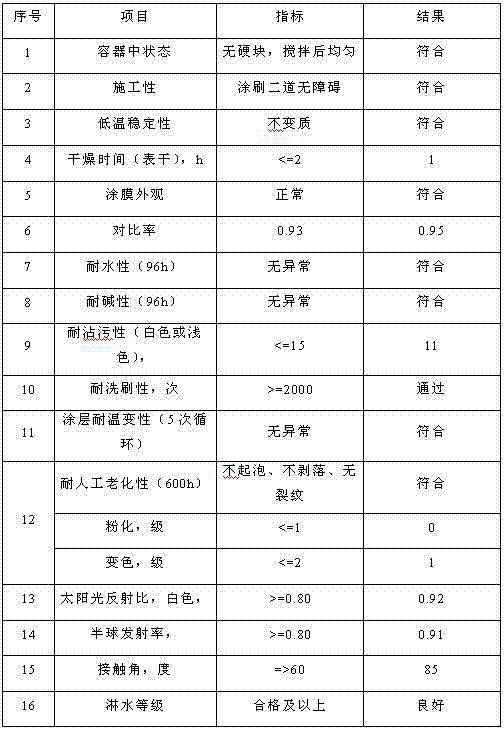

Embodiment 3

[0087] A reflective heat-insulating coating for buildings, in parts by weight, comprising the following components and a preparation method:

[0088] Add 20 parts of water and 0.08 parts of the first thickener (BERMOCOLL EHM300) into the dispersing tank, start the dispersing machine and adjust the speed to about 800 rpm, add 0.55 parts of DA dispersant, 0.2 parts of PE100 wetting agent, 0.4 parts First defoamer (SPA202), 0.4 part of second defoamer (DFC17), 0.25 part of multifunctional additive (AMP95), 0.15 part of preservative (DOA2w), 0.05 part of antifungal agent (H981), stir Evenly, continue to add 25 parts of titanium dioxide, 10 parts of composite heat insulating powder, 2.5 parts of 800 mesh sericite powder, and 4 parts of 800 mesh ground calcium carbonate;

[0089] Pre-emulsify 1.5 parts of ethylene glycol, 1.5 parts of film-forming aid (CS-12), 0.02 parts of emulsifier (T-80), and 1.7 parts of water into the dispersion tank; increase the speed to 1200 rpm and dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com