Medium-length hole ore breaking synergistic anchor cable support subsequent filling mining method of combined reconstructed structural body

A technology of filling mining method and anchor cable support, which is applied in the field of medium and deep hole falling ore cooperation with anchor cable support under the combined reconstruction structure and subsequent filling mining, and in the field of inclined medium-thick ore body, which can solve the problem of high mining cost and poor production safety , economic loss and other issues, to achieve the effect of reducing the amount of mining work, reducing mining costs, and large-scale recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

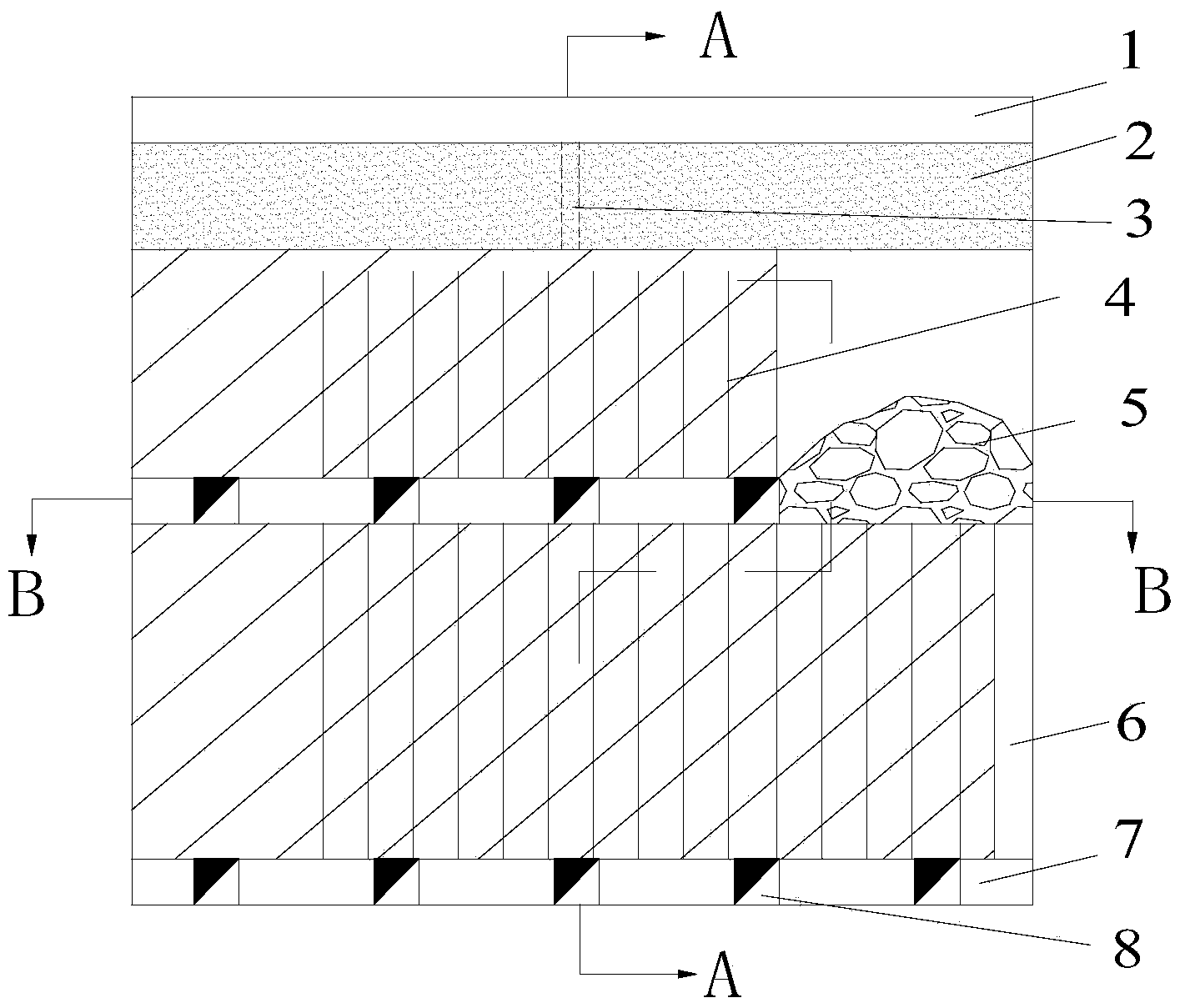

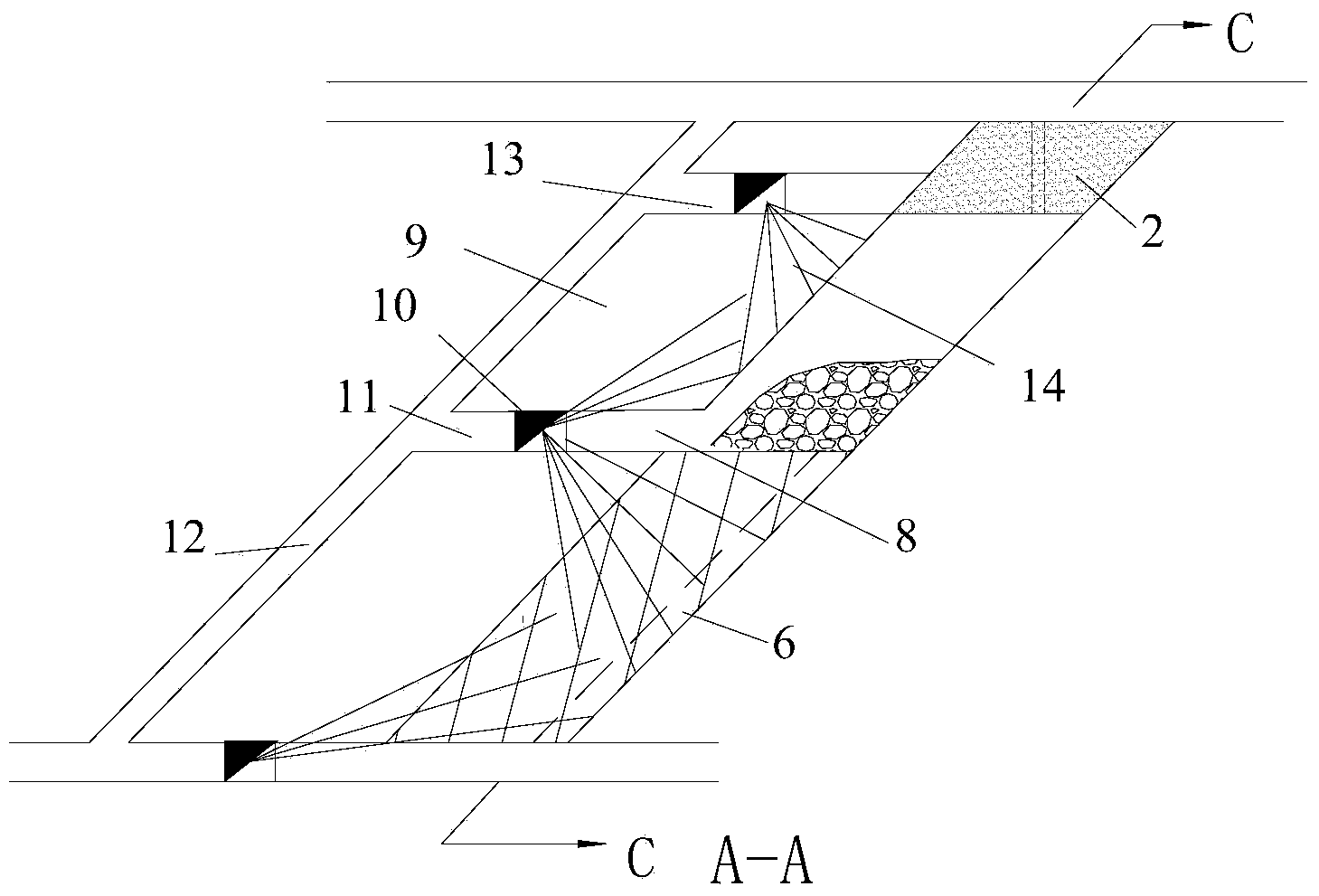

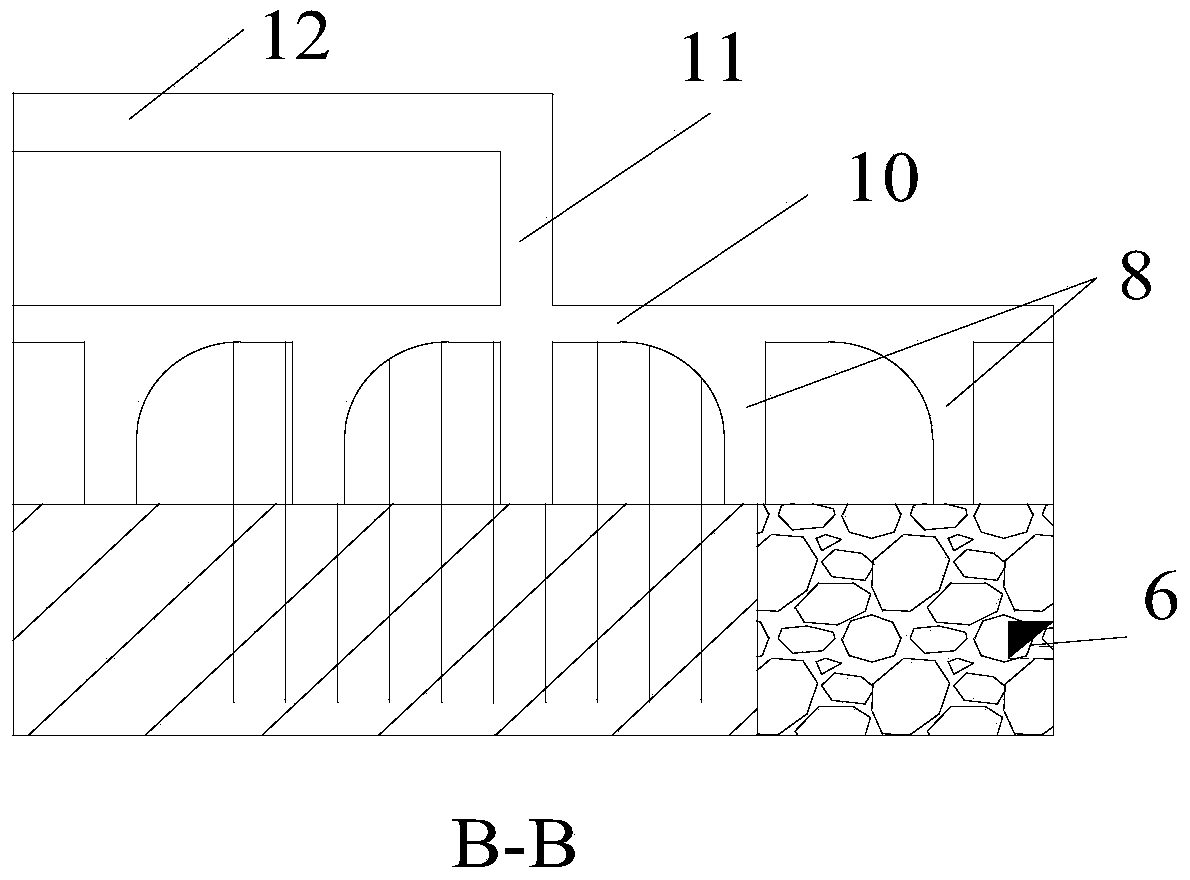

[0019] see figure 1 , figure 2 , image 3 and Figure 4 , the ore body is divided into the middle section, and when the middle section is divided into stopes, the upper and lower middle section stopes are staggered to carry out downward mining. Drill and cut the raised well 6 in the footwall of the ore body, and use the cut raised well 6 as the blasting free surface to form a cutting groove, which is used as the blasting free surface for the subsequent large-scale mining work. The uphill approach road 12 is excavated in the surrounding rock of the ore body hanging wall, and is connected with the horizontal transportation roadway 1 to form a mining area transportation system. Excavate the roof-cutting route 13 in the middle section of the roof to reach the ore body, build the artificial false roof 2 after the roof-cutting work is completed, and reserve a filling pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com