Air column well completion back coming subsequent filling mining method

A backfill mining method and air column technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of complex procedures, large dilution loss rate, and impact on the mining progress of the access mining method, so as to save mining costs, The effect of large production capacity and eliminating the need for the construction of the patio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

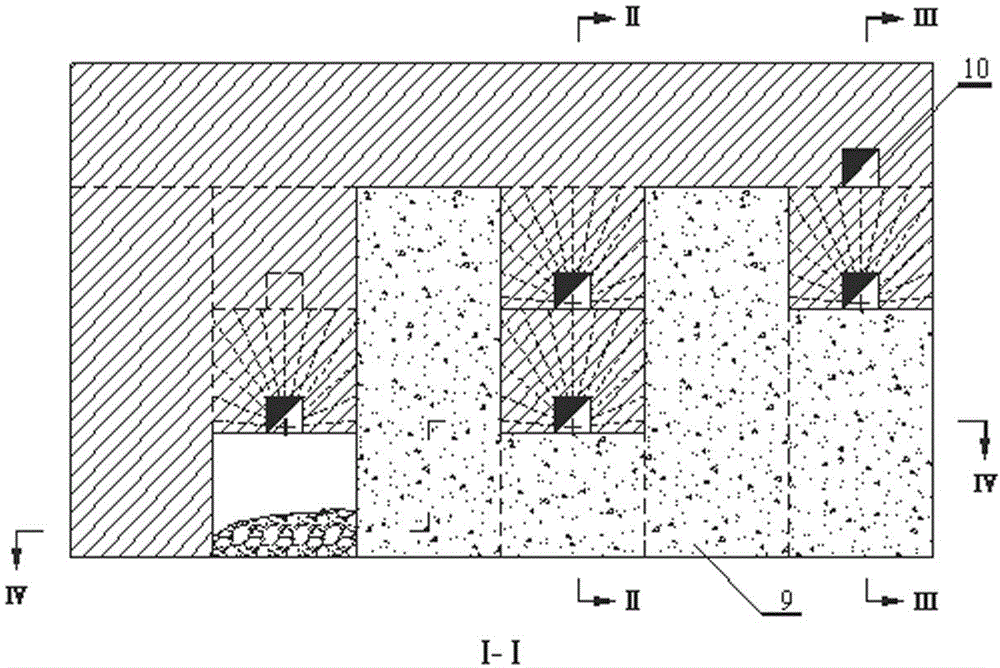

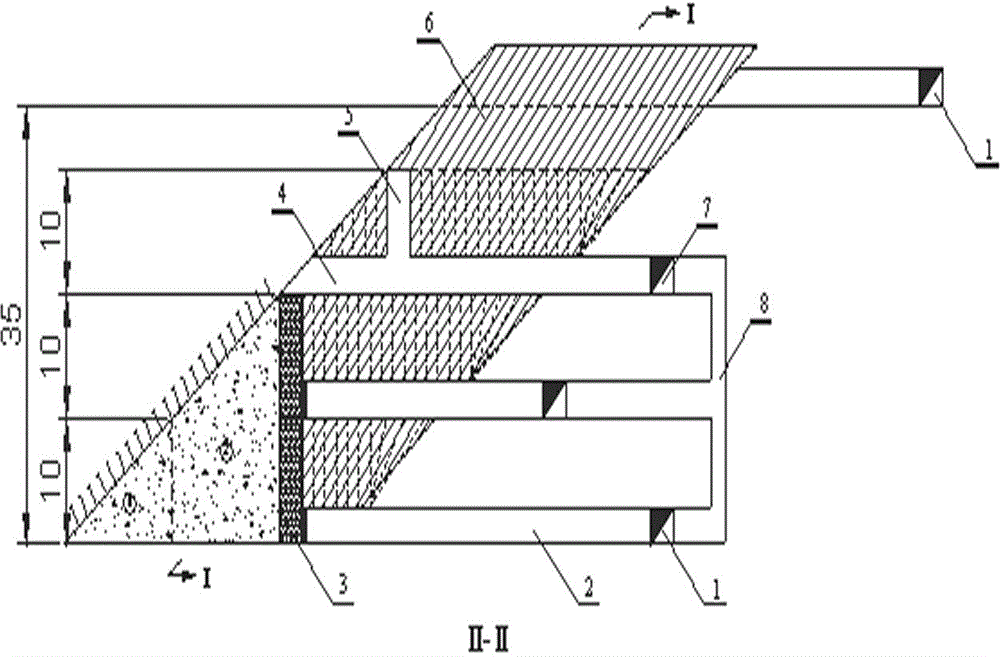

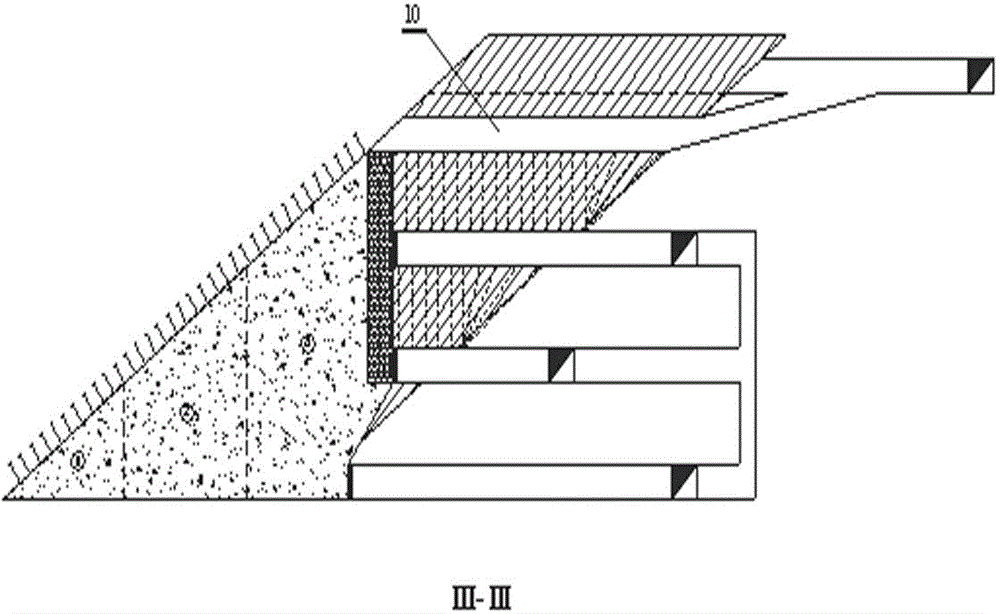

[0024] Method of the present invention is as follows:

[0025] (1) Divide the ore body into sections on the vertical height for mining, and divide the stope along the direction of the fragment as the mining unit. Each stope uses medium and deep holes to retreat from the upper wall to the lower wall. Multi-segmentation simultaneously Mining, control the exposed area of the stope roof, mining a mining unit each time, filling and curing before proceeding to the mining of the next mining segment;

[0026] (2) The middle and deep holes are used to drop the ore, and the scraper is used to extract the ore, and it is mined from the upper wall of the ore body to the lower wall. For the sake of safety, the mining unit of the lower wall is too high to control the top distance, and the remote control scraper can be used to control the caving. ore for recycling;

[0027] (3) The air column is lowered from the upper section through the veins, and it is arranged in the center of the mine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com