Method for promoting gas extraction and working face dust fall by injecting water at intervals in drilling holes

A technology of gas extraction and through-layer drilling, which is applied in the directions of gas discharge, earth-moving drilling and dust-proofing, etc., can solve the problem of not being able to take both into account, reduce the chance of gas exceeding the limit, reduce the content of coal dust, and improve the gas The effect of the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and a test example (310205 working faces of Xinyuan Coal Mine of Yangmei Group) the present invention will be further described.

[0020] A method for promoting gas drainage and dust reduction in working faces by injecting water at intervals in boreholes through layers, comprising the following steps:

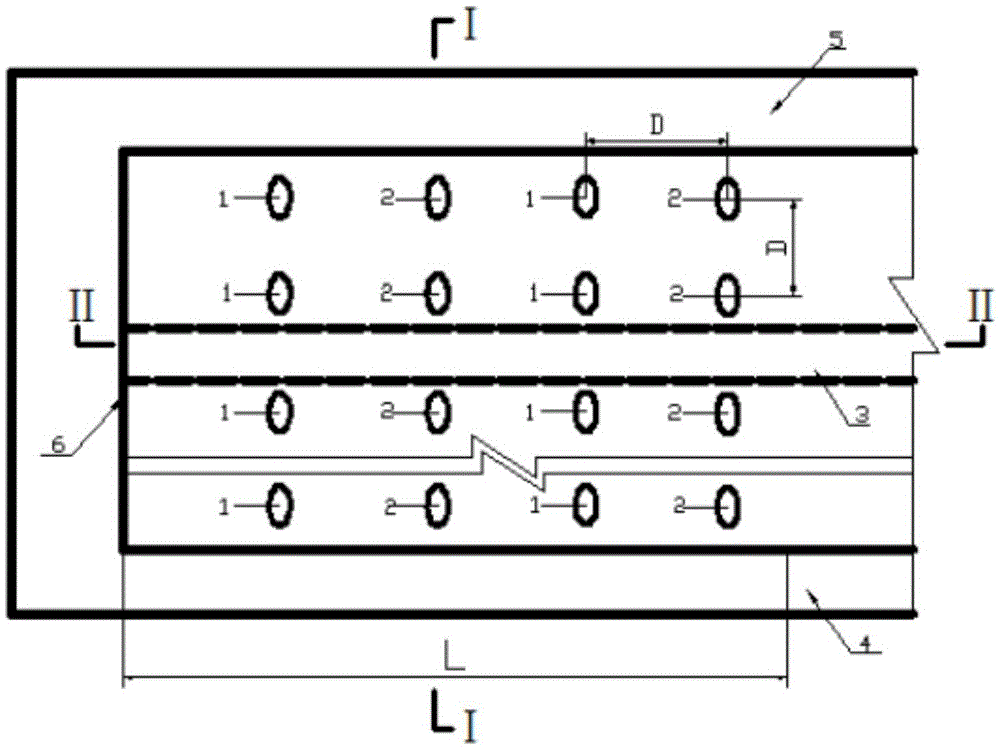

[0021] (1) According to the actual situation of the 310205 working face of Xinyuan Coal Mine, the coal mining working face and production system are designed and arranged according to the rules and regulations, and the length of the working face is 240m;

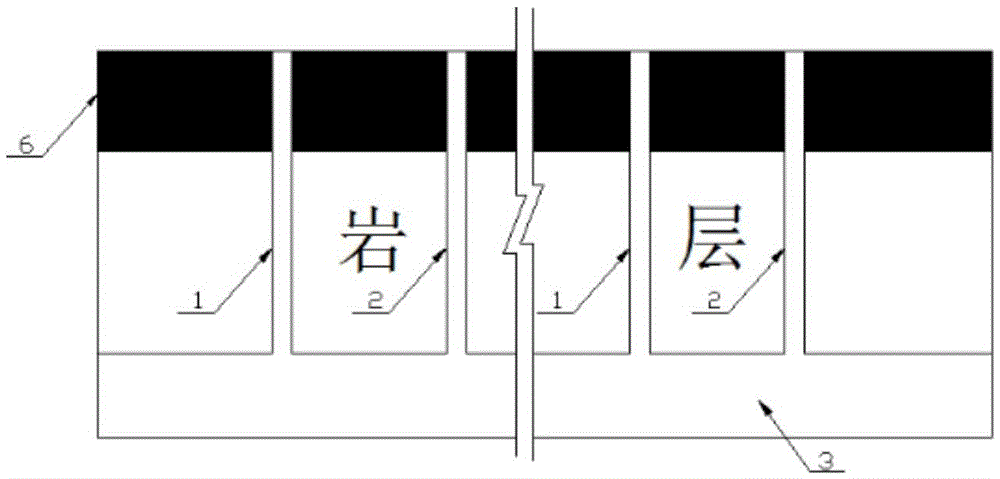

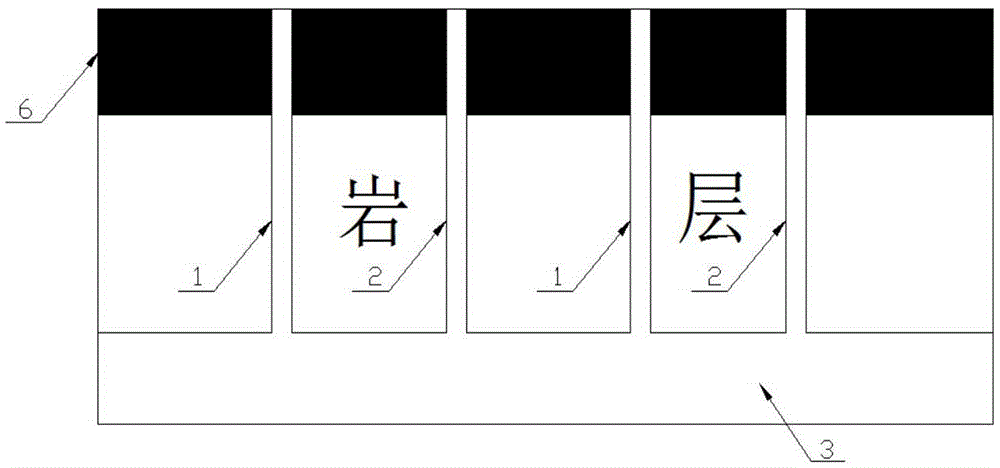

[0022] (2) According to the mining technical conditions of the 310205 working face of Xinyuan Coal Mine, the final hole distance D=5m between two adjacent interlayer drillings along the direction of the floor rock roadway is determined; Starting at a distance of 5m, several groups of interlayer drilling holes are constructed in the coal seam along the direction of the coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com