A low-order pulverized coal rotary drying process with dust removal

A technology of rotary drying and pulverized coal, which is applied in the direction of non-progressive dryers, drying, drying machines, etc., can solve the problems of ineffective mechanical screening and a large amount of coal dust in the product, so as to improve the yield and increase the yield of coal tar Quality, reduce equipment and production costs, reduce the effect of coal dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

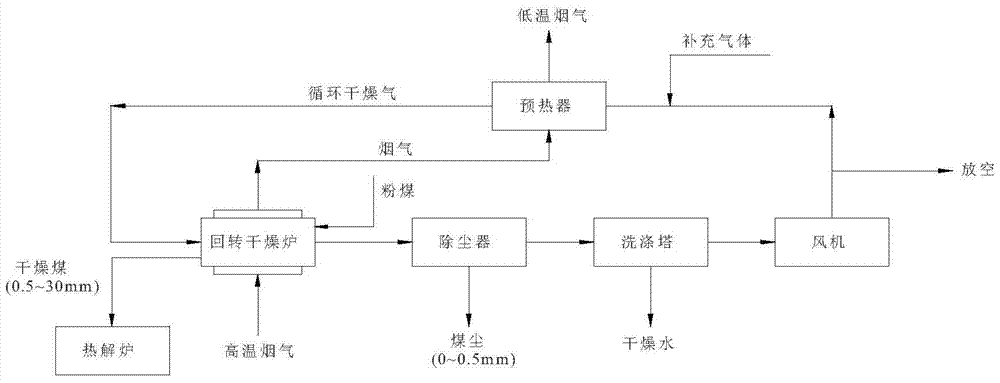

[0044] 6000kg raw long-flame coal with a particle size of ≤30mm is continuously added to the rotary drying furnace from the furnace head, and at the same time, 2kpaG, 200°C flue gas (O 2 Content ≤ 5vol%) contact with coal countercurrent as dedusting gas; 600°C high-temperature flue gas is introduced into the jacket of the rotary drying furnace as the drying heat source, and the flue gas at the outlet enters the preheater to heat and circulate the drying gas and then empties. After the coal is heated and dried to 250°C and the water content is 0%, it is sent to the downstream pyrolysis furnace. The gas at 115°C at the furnace head outlet of the rotary drying furnace enters the bag filter, washing tower, fan, and preheater in sequence, and performs unit operations such as dust removal, temperature reduction and recovery of dry water, pressurization and temperature rise, and then returns to the rotary drying furnace to form Closed circulation of drying gas. See the schematic dia...

Embodiment 2

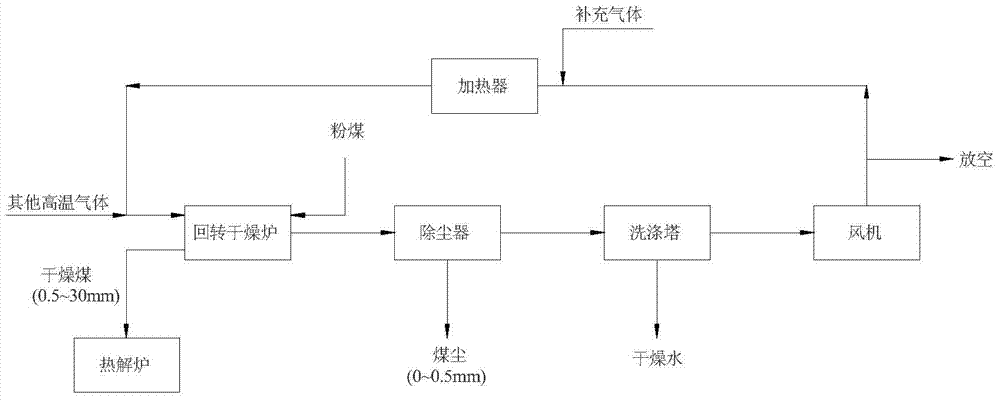

[0055] 1000kg of raw material long-flame coal with a particle size of ≤30mm is added to the rotary drying furnace from the furnace head, and 2kpaG, 500°C flue gas (O 2 Content 2vol%) contacts with coal countercurrently, and the dry gas at 200°C at the outlet enters the metal filter to remove coal dust, then enters the water cooler and gas-liquid separation tank to recover most of the dry water, and then returns to rotation after being pressurized by the fan and heated by the heater The tail of the drying furnace forms a closed loop of dedusting gas. At the same time, add a small amount of low-pressure N at the inlet of the heater 2 , vent the same amount of gas at the outlet of the fan to control the O of the dust removal gas in the rotary drying furnace 2 Content 3vol%. See the schematic diagram of the process flow figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com