Single-bag grouting hole sealing device for upward crossing boreholes and hole sealing method adopting single-bag grouting hole sealing device

A technology of sealing device and bag, which is applied in the direction of safety device, sealing/seal, earthwork drilling and mining, etc., which can solve problems such as difficult to maintain grouting pressure, air leakage, sealing effect, etc., to avoid coal wall cracks , Improve work efficiency and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

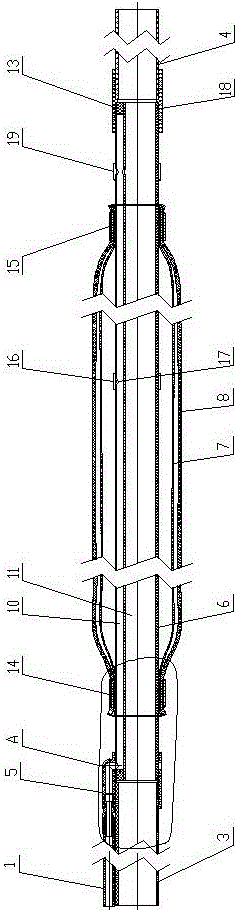

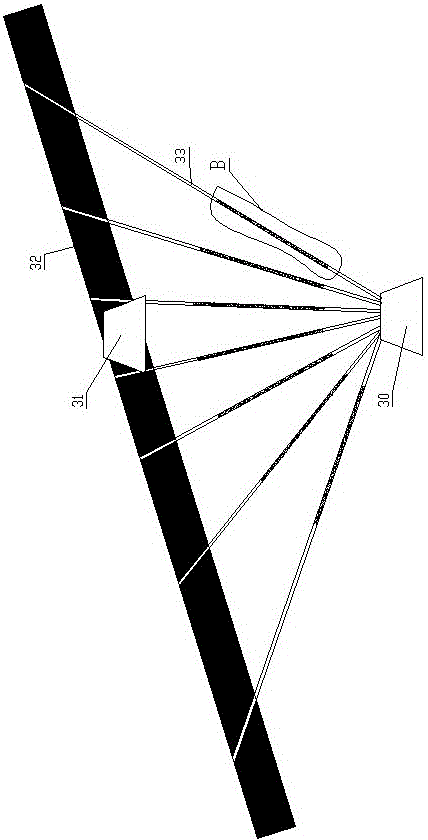

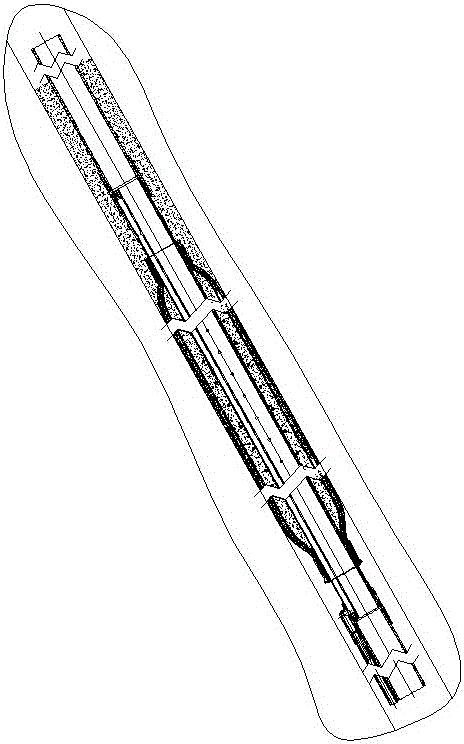

[0025] Such as figure 1 with 2 As shown, the single-bag grouting and sealing device for cross-layer upward drilling of the present invention includes a recyclable grouting pipe 1, a grouting pipe joint 2, a front gas drainage pipe 3, a rear gas drainage pipe 4, and a drainage device 5. The double-hole pipe 6 and the expansion bush 7, the front end of the double-hole pipe 6 is connected with the rear end of the front gas extraction pipe 3 through the drainage device 5, and the rear end of the double-hole pipe 6 and the front end of the rear gas extraction pipe 4 pass through the rear clamp 18 connection; the double holes in the double-hole pipe 6 are respectively the grouting channel 10 and the drainage channel 11, and the front and rear ends of the drainage channel 11 are respectively connected with the front gas drainage pipe 3 and the rear gas drainage pipe 4, and the expansion bushing 7 is cylindrical and hollow inside, and the expansion sleeve 7 is covered with an expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com