Coal mine working face gas geological risk evaluation method

An evaluation method and technology of the working face, applied in the direction of instruments, complex mathematical operations, data processing applications, etc., can solve the problems of lack of pertinence of prevention and control measures, lack of detailed research on gas geology at the working face scale, and inability to effectively predict gas risks, etc. Reliable effect of grading and partitioning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

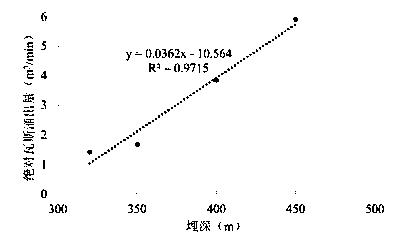

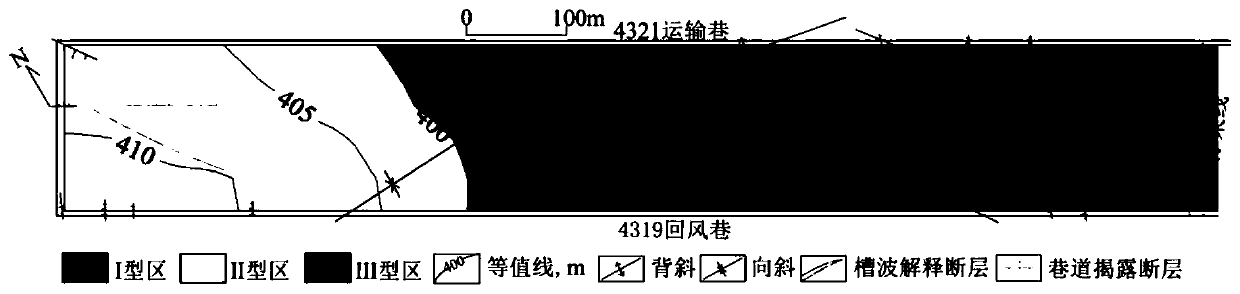

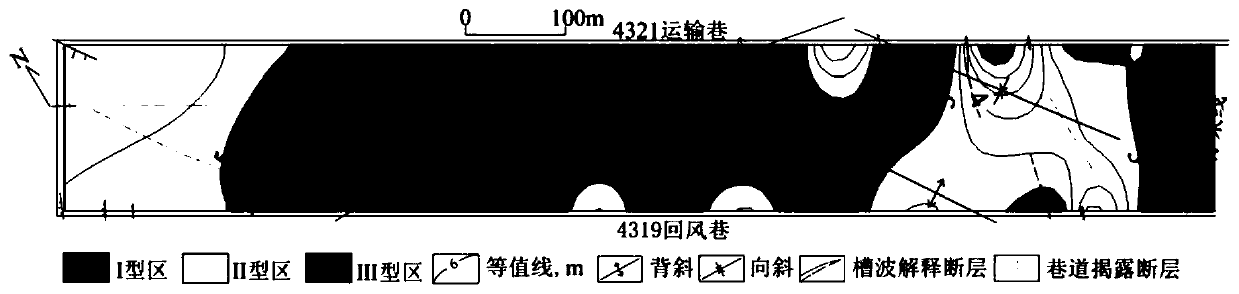

[0045] Based on the graded evaluation index and method proposed by the present invention, a mining face in the northern part of the Hancheng mining area is analyzed. The working face has a total length of 1149.49m and a width of 166.18m. The mined coal seam is No. 3 coal. At present, the cutting eye has been completed and the mining is expected to be completed in June 2020. Based on roadway foundation measurement data, coal structure catalog data, residual gas content test data, ventilation gas report and geophysical detection data, kriging interpolation method is used to draw the coal seam thickness, roof elevation, buried depth, coal structure, The absolute gas emission volume and residual gas content isoline distribution map, carry out gas geological single factor evaluation, and realize the comprehensive gas geological evaluation of the working face on this basis.

[0046] Basic characteristics of coal seam

[0047] (1) Buried depth

[0048] The burial depth of the No. 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com