Pure water production system

A production system, pure water technology, applied in multi-stage water treatment, water/sewage treatment, non-polluting water treatment and other directions, can solve the problems of increasing production costs, increasing the living burden of consumers, reducing production efficiency, etc. Ingenious, simple structure, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

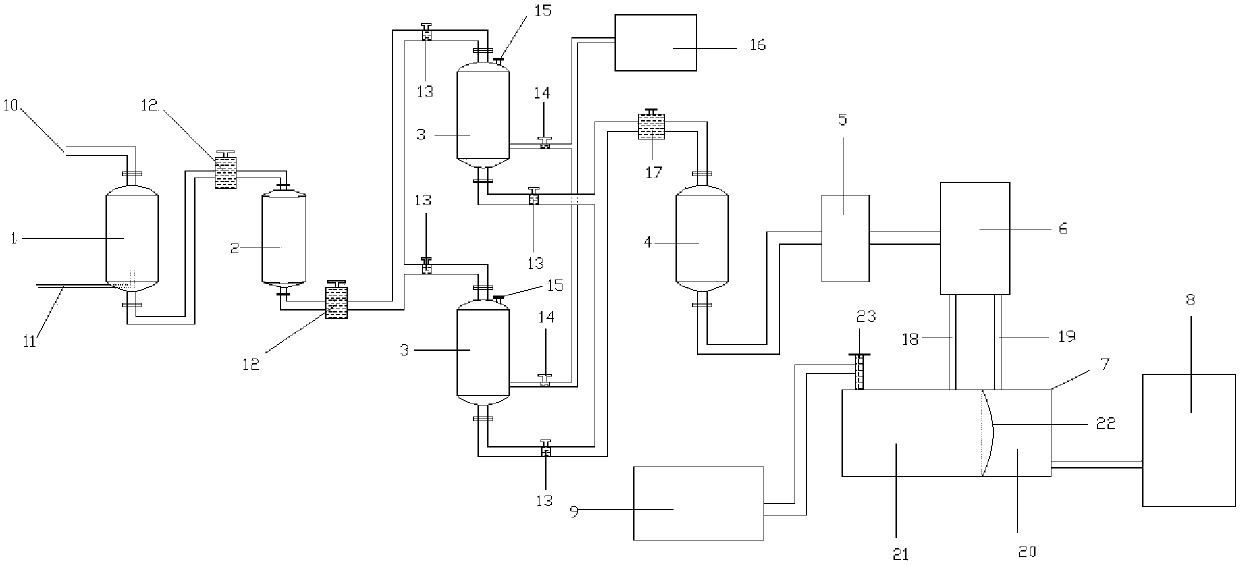

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, the pure water production system of the present invention includes a quartz sand tank 1, a precision filter 2, an activated carbon tank 3, a resin tank 4, a security film 5, a reverse osmosis device 6, and a water storage tank 7 connected in sequence through a water delivery pipe. And canning equipment 8, described water storage barrel is made of waste water chamber 21 and pure water chamber 20, and the water inlet of described waste water chamber 21 is connected with the waste water pipe of reverse osmosis device 6, and the water inlet of described pure water chamber 20 It is connected with the pure water pipe of the reverse osmosis device 6, the water outlet of the pure water chamber 20 is connected with the canning equipment 8, and a flow-making pipe 11 is also arranged at the bottom of the quartz sand tank, and the pipe of the flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com