Net rack production line for producing heat insulation board wall

A thermal insulation board and production line technology, applied in online, application, household appliances, etc., can solve problems such as poor thermal insulation effect, short service life, long construction period of building exterior walls, etc., to reduce manual labor, improve production quality, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with specific embodiments.

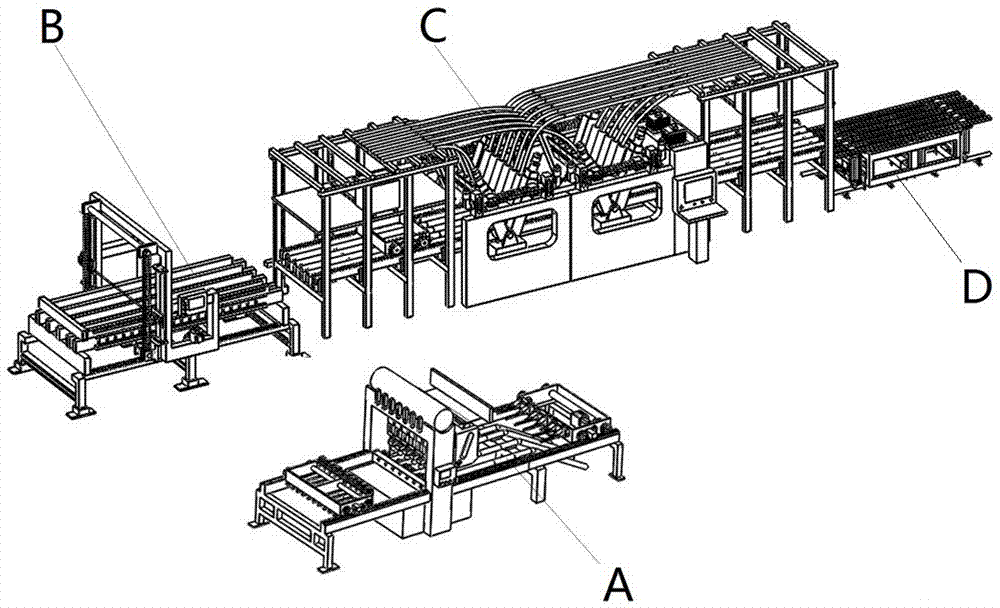

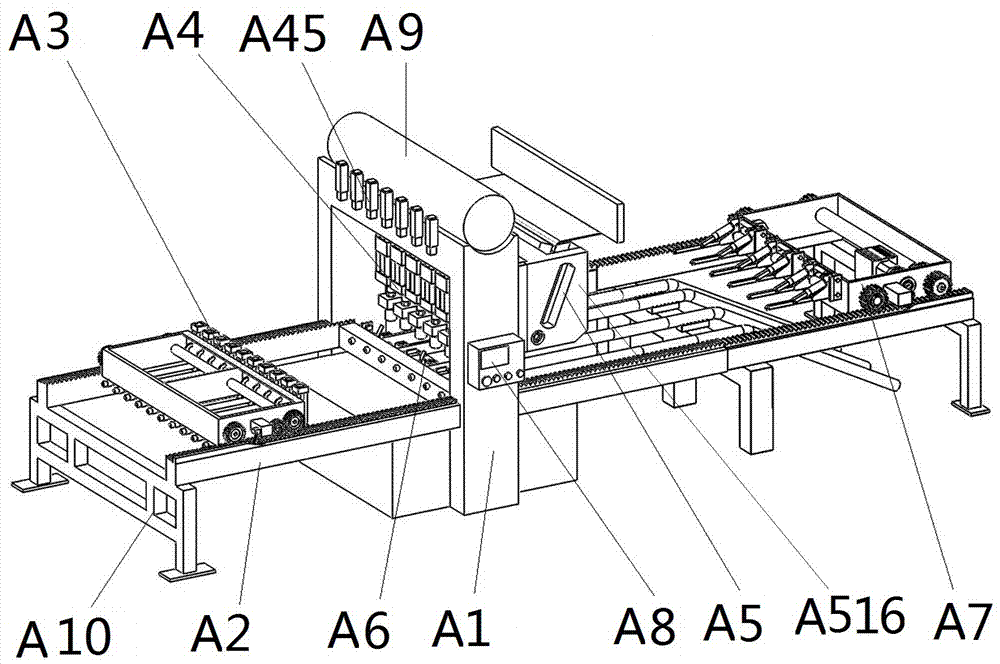

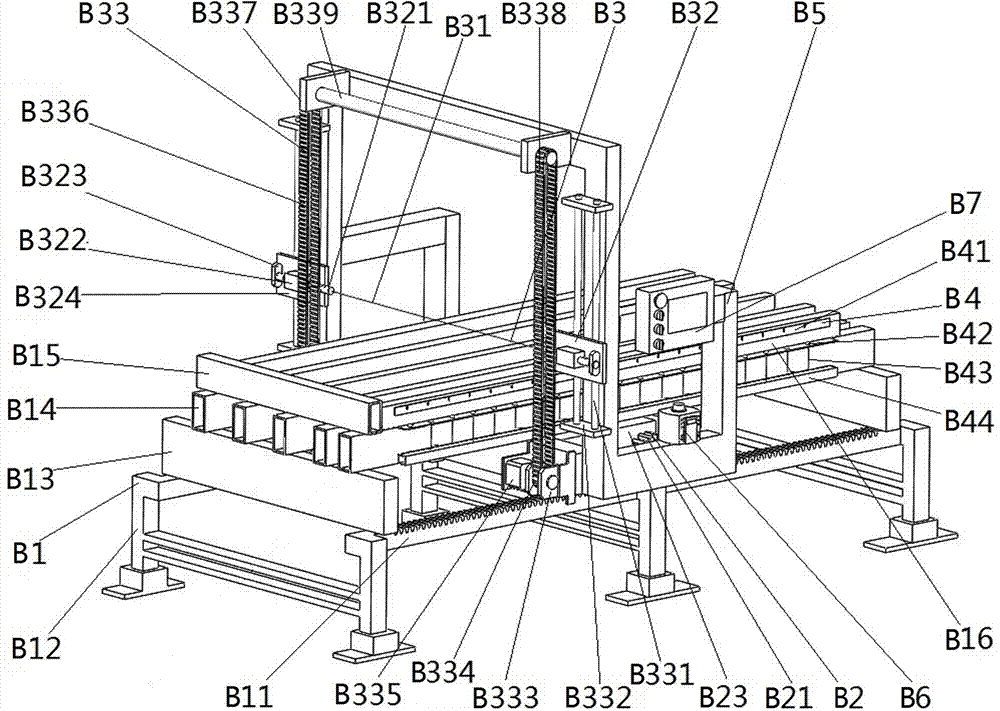

[0058] The production line of grid frame for insulation board wall, combined with Figure 1 to Figure 9 As shown, it includes flat screen welding machine A, insulation board cutting machine B, oblique rib welding machine C and grid insulation board conveyor D. Flat mesh welding machine A is used to weld the straightened longitudinal and transverse bars into a flat mesh layer; insulation board cutting machine B is used to cut the thickness and length and width directions of the insulation board and can cut out insulation boards that meet the specifications; The oblique rib welding machine C is used to insert the oblique ribs into the insulation board and cut them off, and can weld the oblique ribs to the upper and lower flat mesh layers; the grid insulation board conveyor D is used to transport the completed grid insulation board into place. The feeding end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com