Patents

Literature

33results about How to "Reduce soil content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

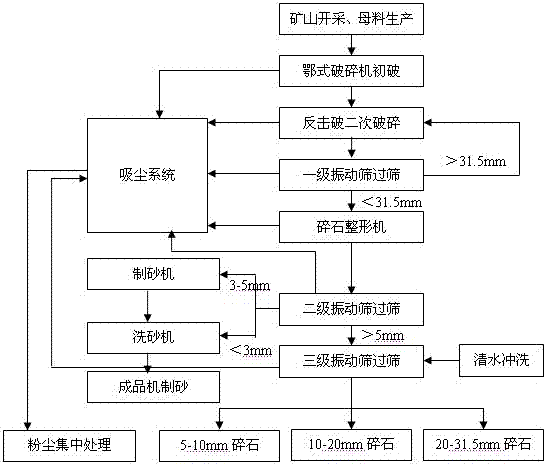

Machine-made sand processing process

ActiveCN102806133ALow stone dust contentReduce soil contentGrain treatmentsCrushed stoneProcess engineering

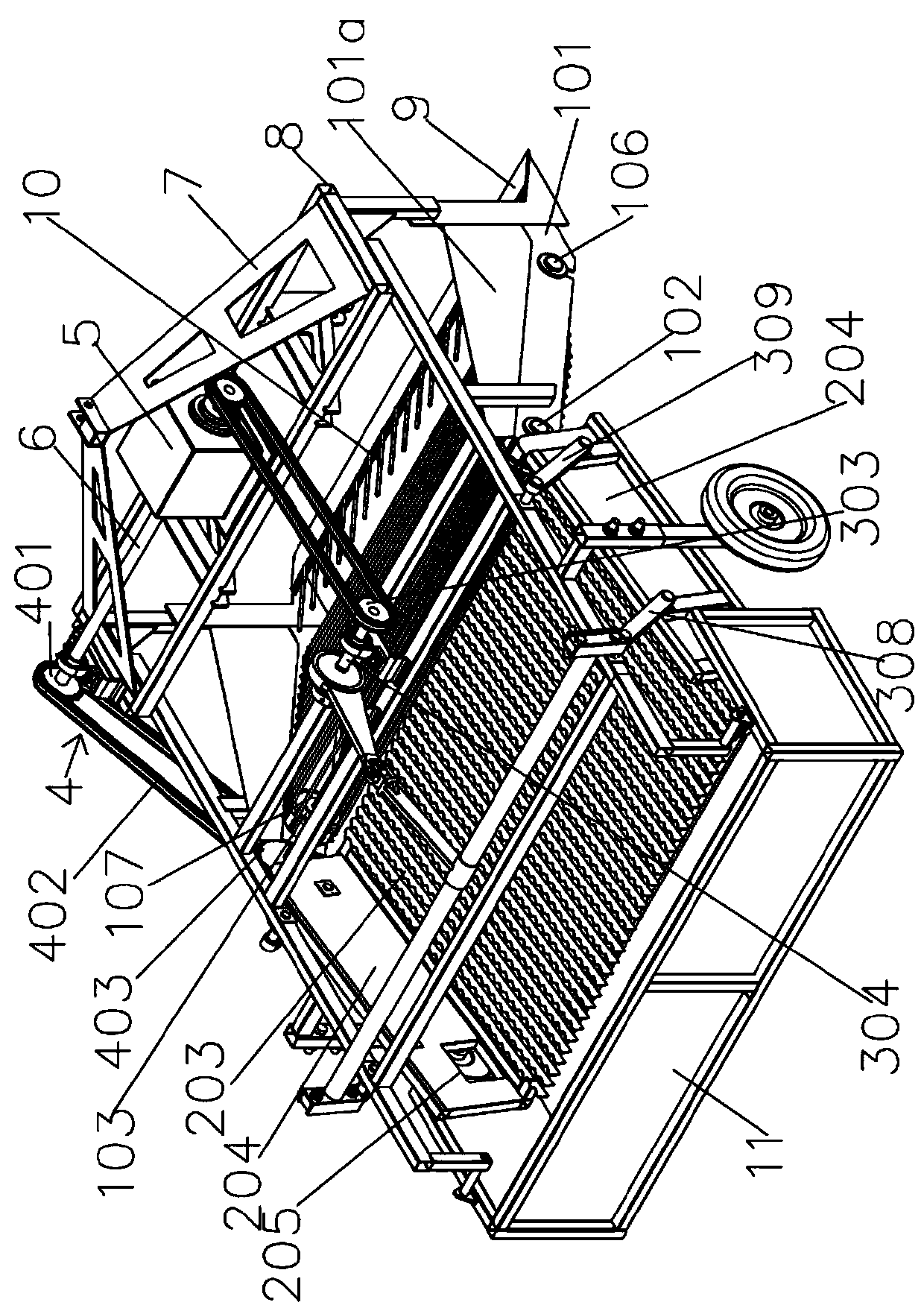

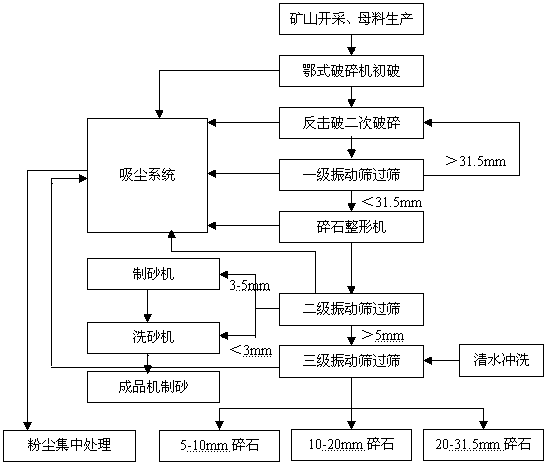

The invention discloses a machine-made sand processing process, which comprises the following processes that stone materials enter a jaw crusher to be decomposed into stone blocks not greater than 350mm, and then, the stone blocks enter a reverse smashing machine; the stone blocks are crushed into crush stones by the reverse smashing machine, the crushed stone enters a primary vibration sieve to be screened, the crushed stones smaller than 31.5mm enter an impact type crusher, and the crushed stones greater than 31.5mm return the reverse smashing machine to be crushed; after entering the impact type crusher to be crushed, the crushed stones enter a two-grade vibration sieve to be screened, and sand smaller than 3mm enters a sand washing machine; sand greater than 3 to 5mm enters an efficient fine crushing machine to be made into sand smaller than 3mm, and the sand smaller 3mm enters the sand washing machine after entering two-grade vibration sieve to be screened; the crushed stones greater than 5mm enter a three-grade vibration sieve; the crushed stones are screened into the crushed stones in three grades by the three-grade vibration sieve, and the crushed stones are used for material discharge in the vibration sieve after being flushed by water. The machine-made sand produced by the process provided by the invention has the advantages that each index can respectively meet the technical index of high-performance on machine-made sand, and the product quality is high, and stability and reliability are realized.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

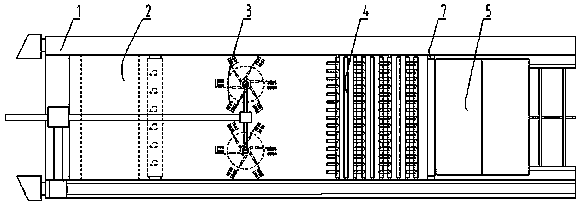

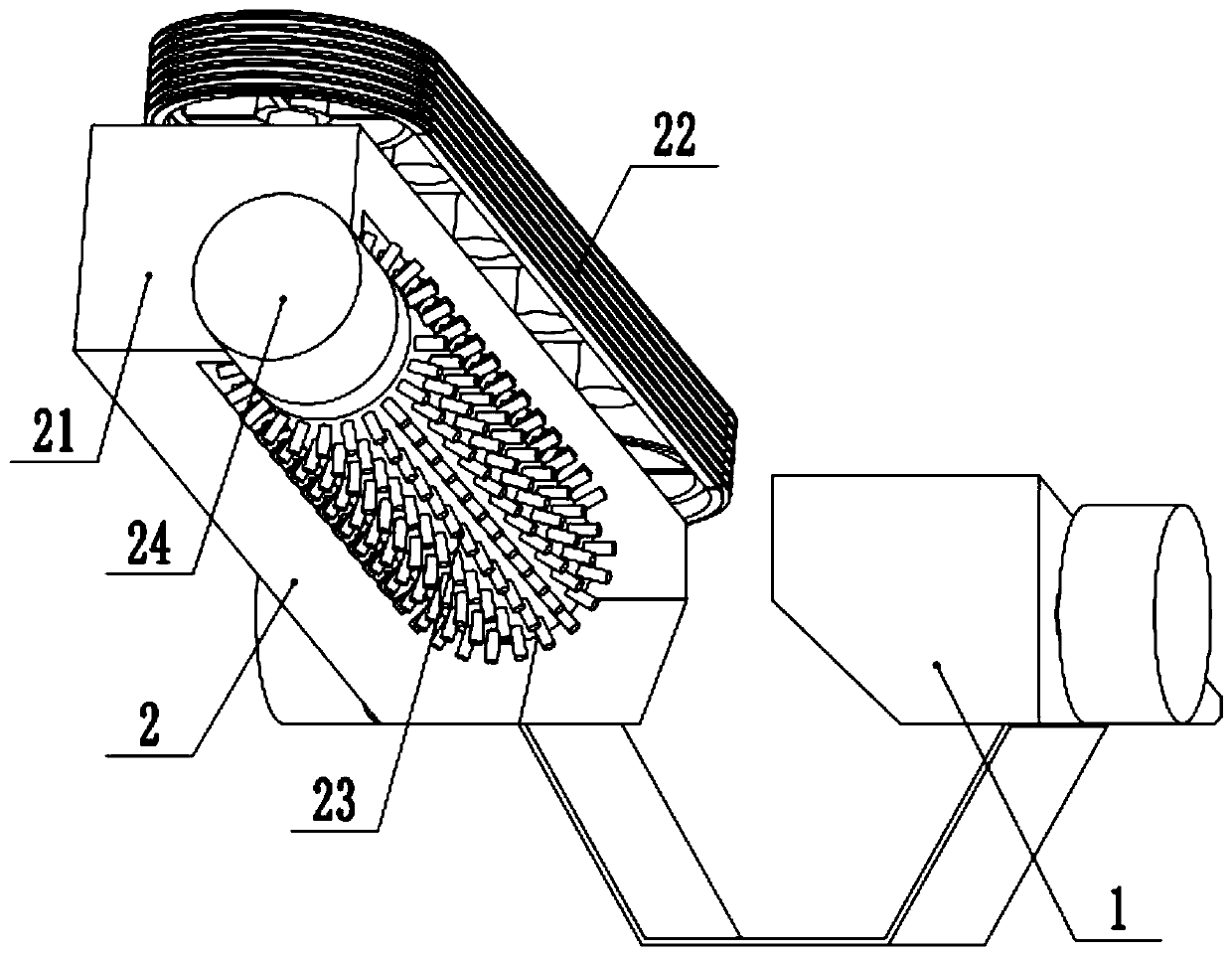

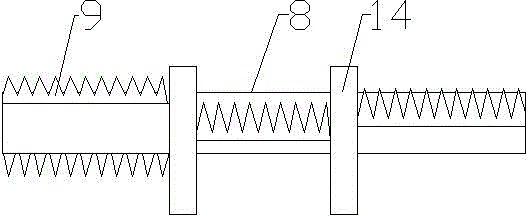

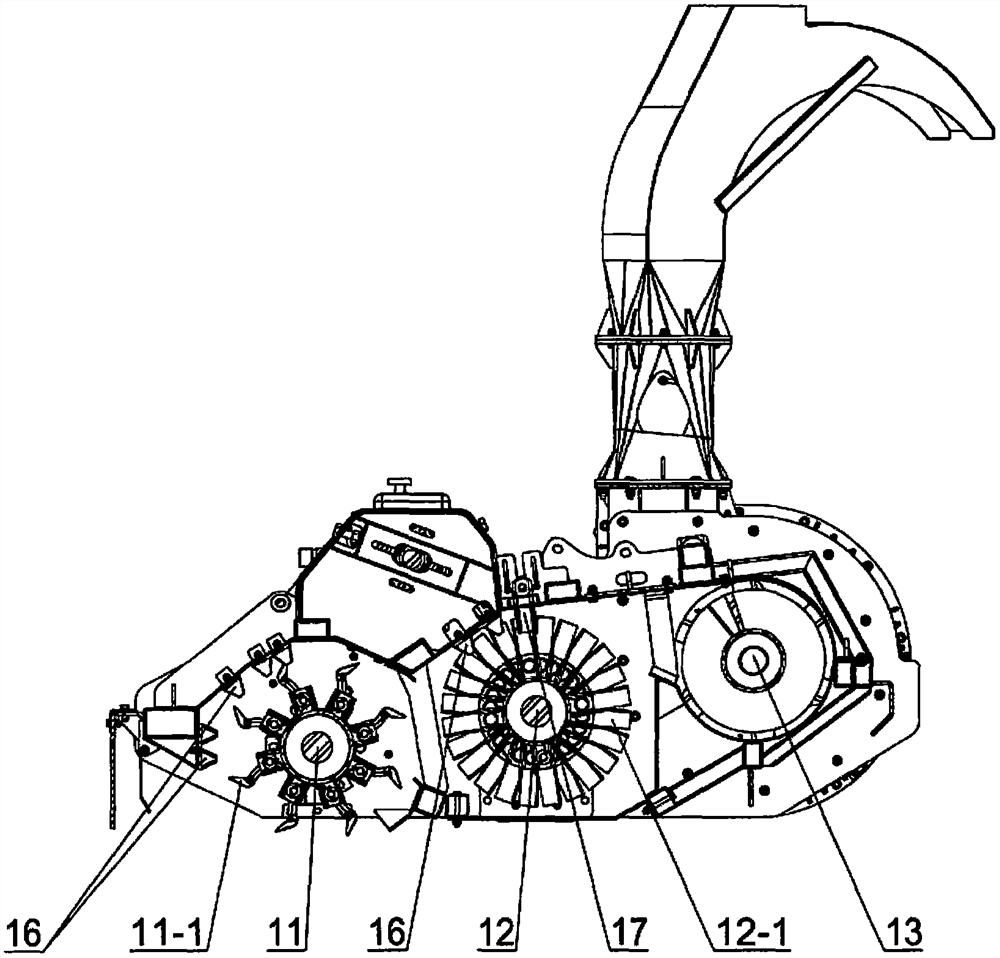

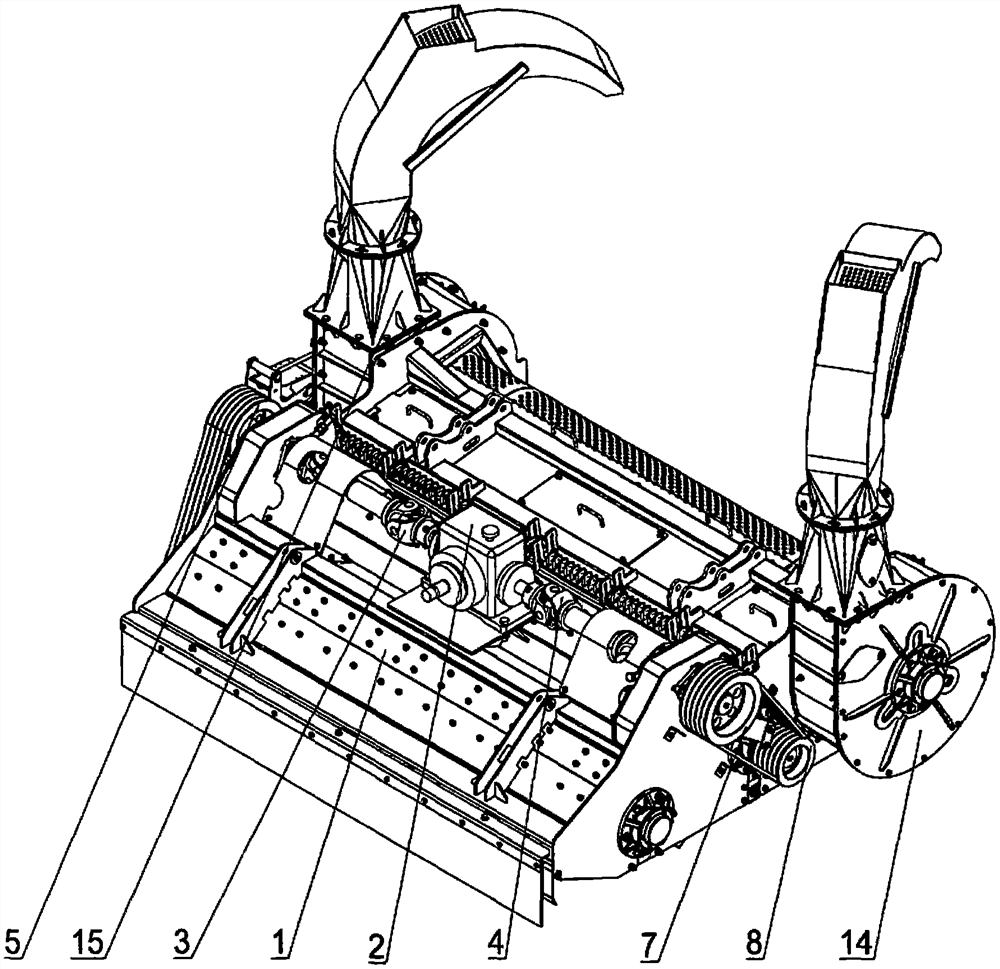

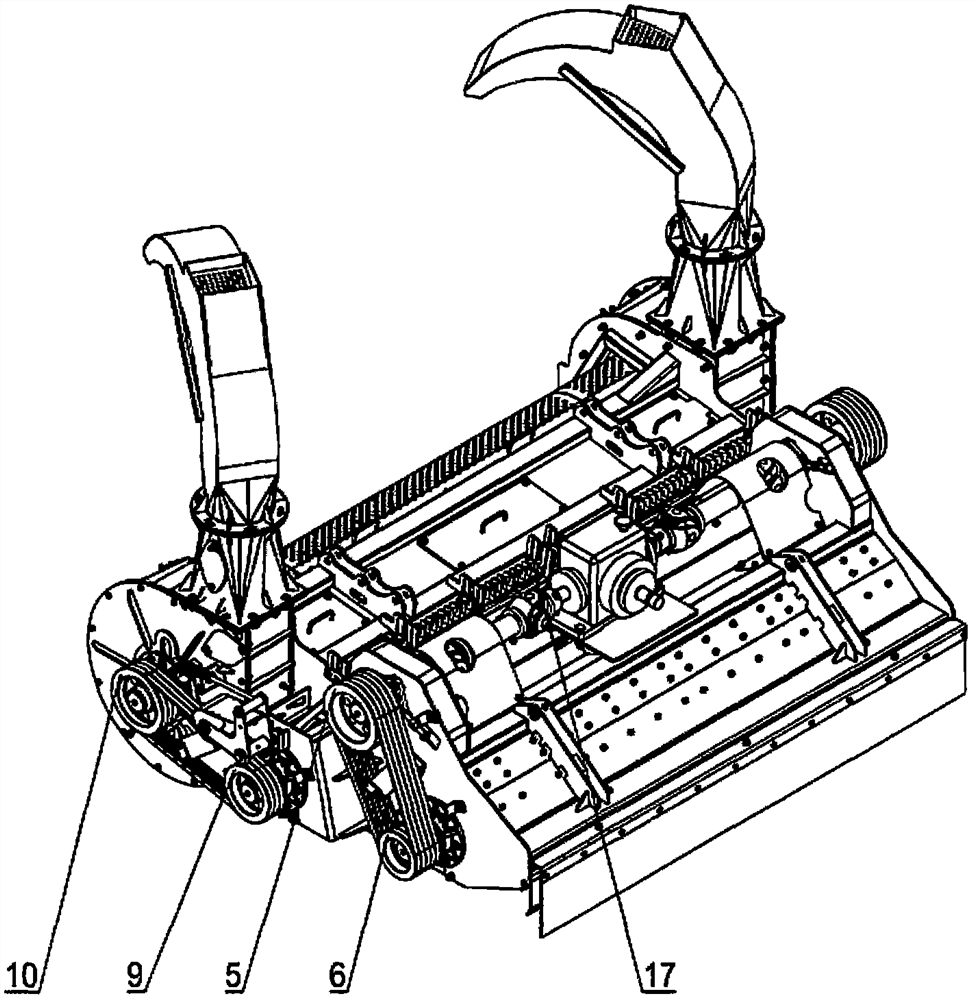

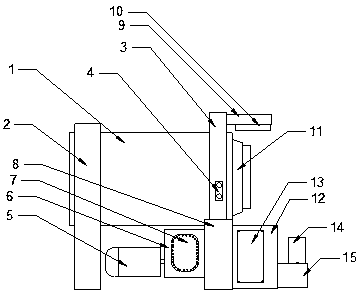

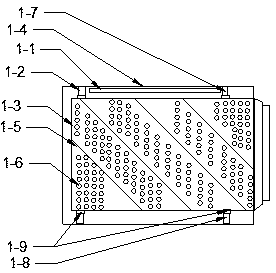

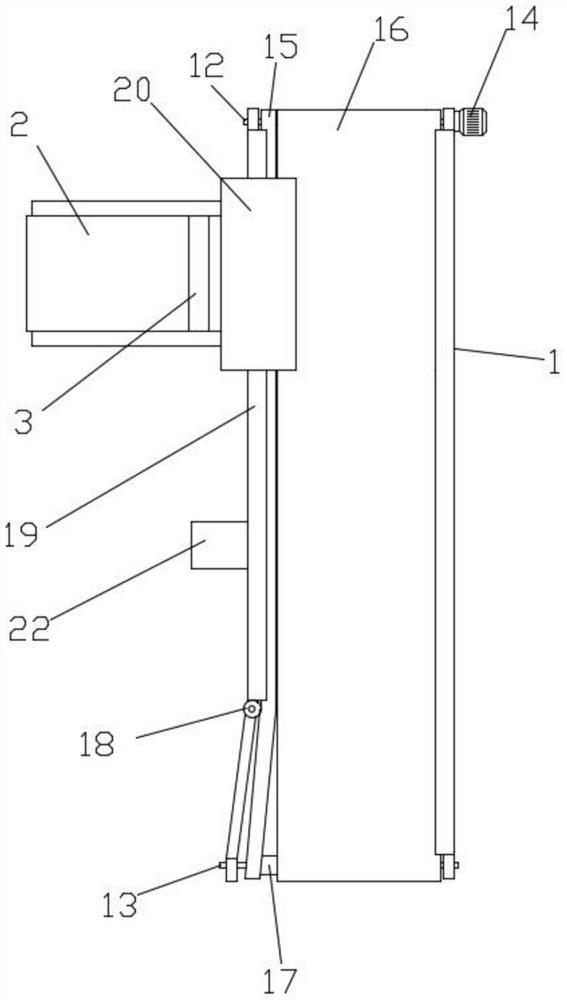

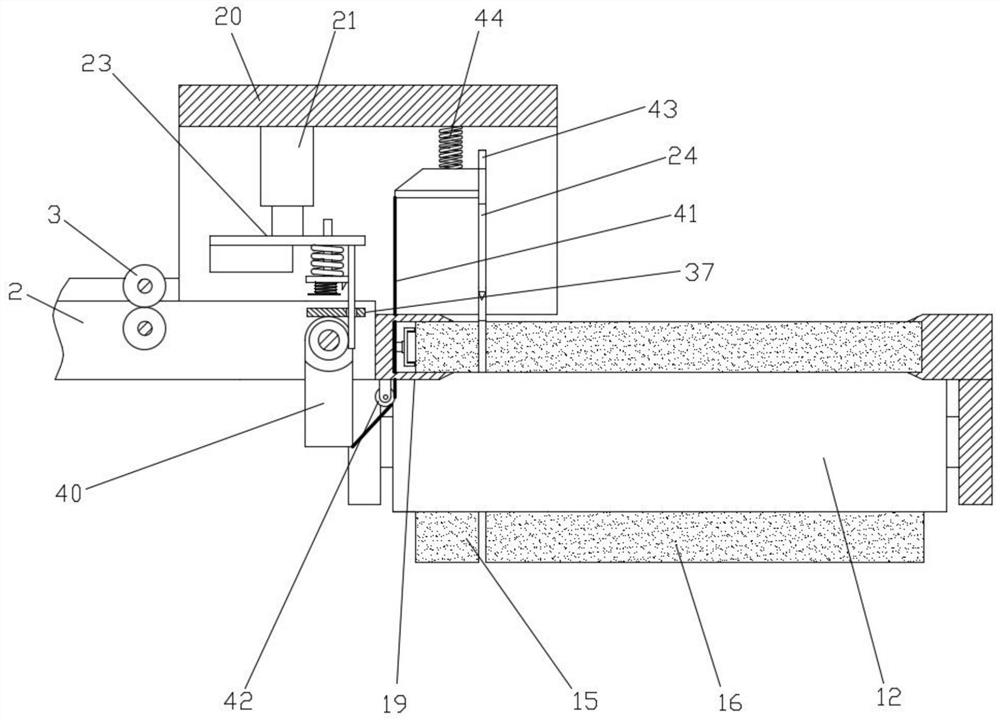

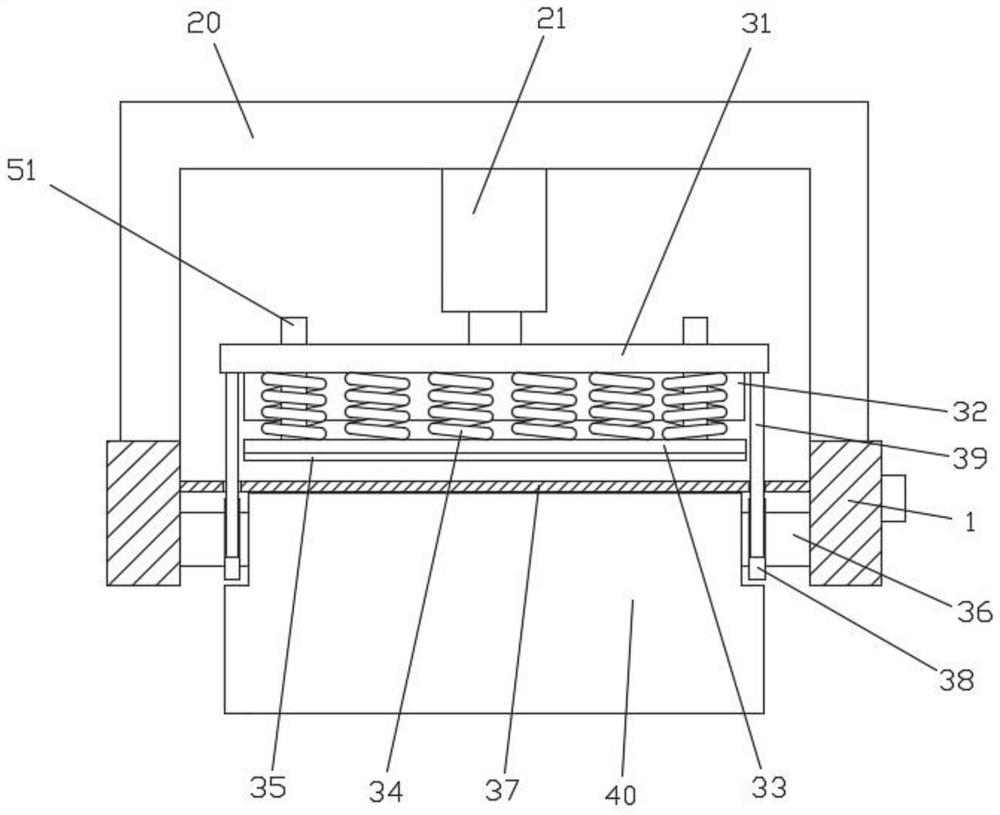

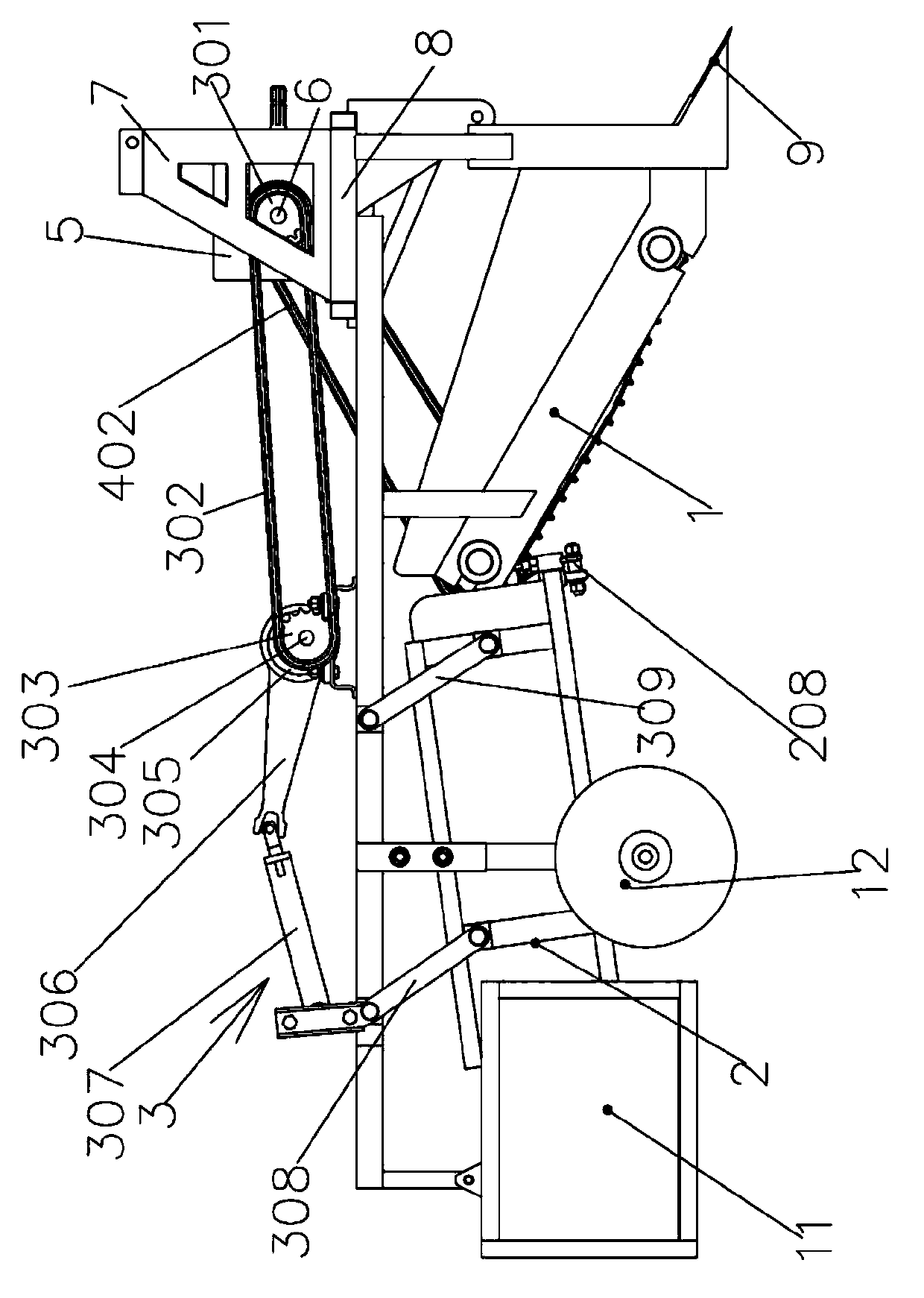

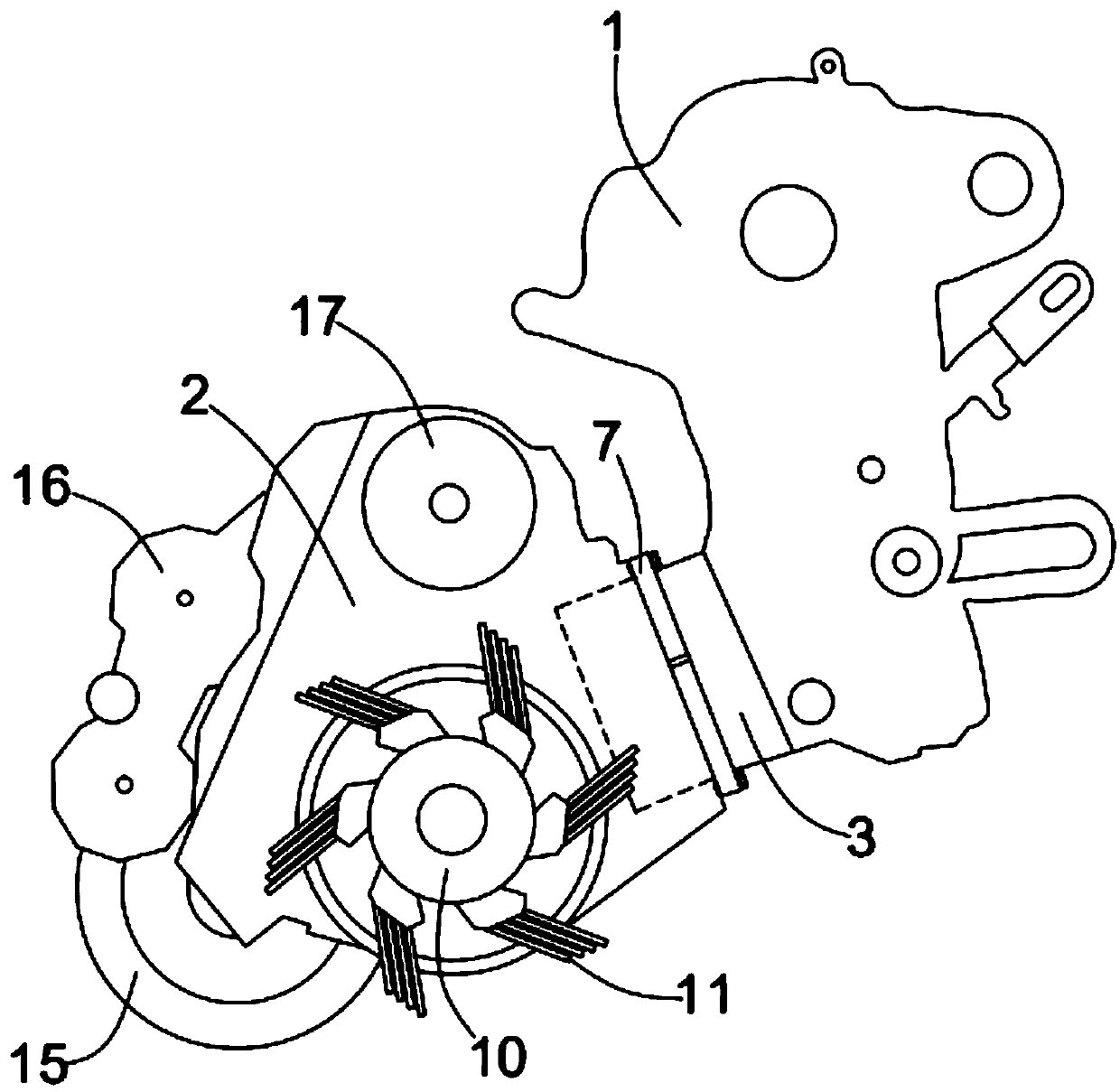

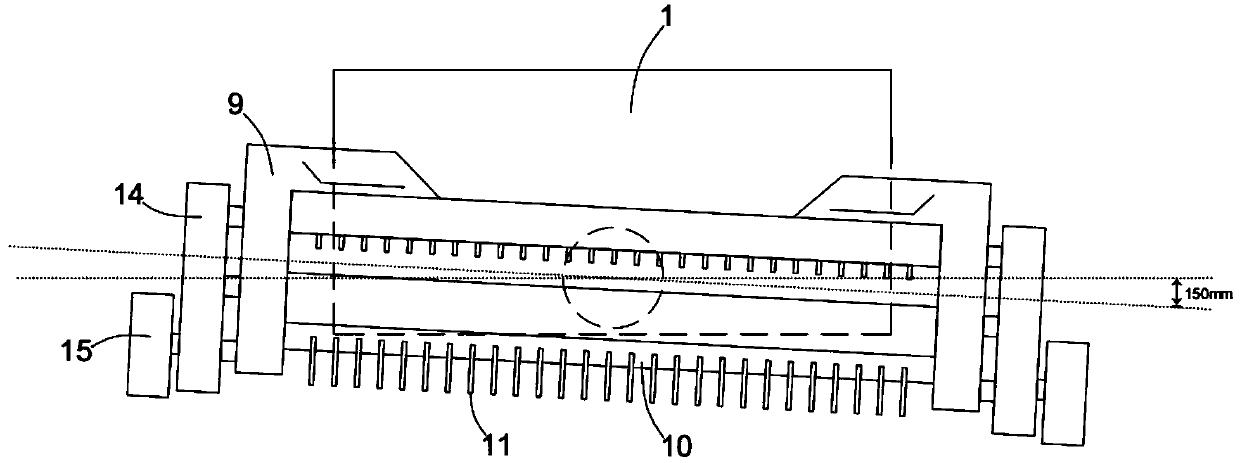

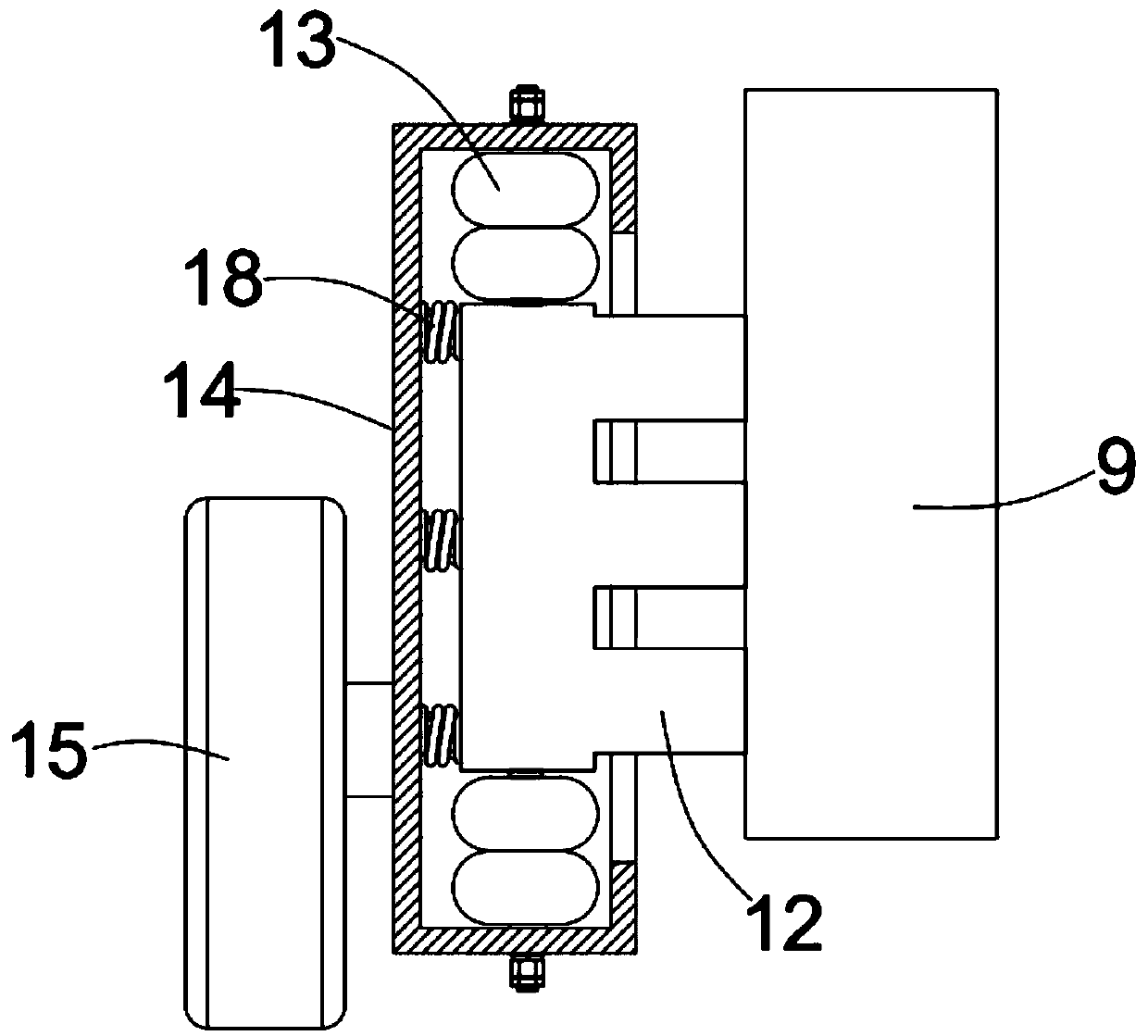

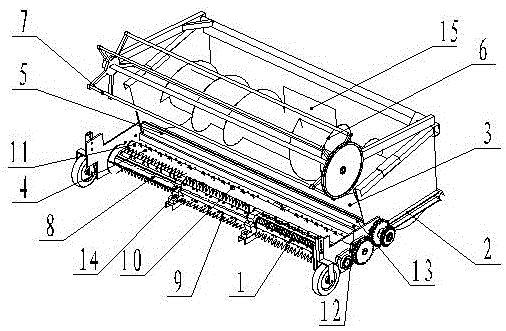

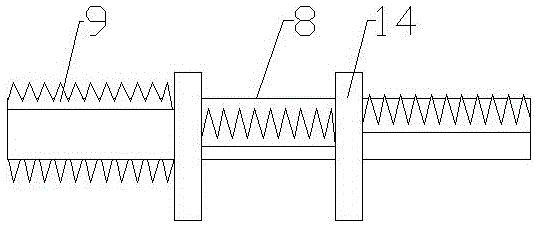

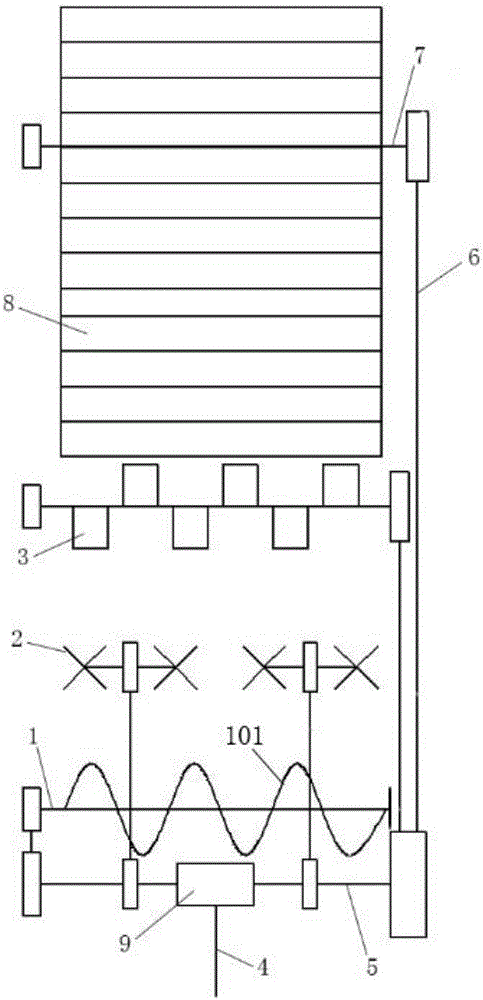

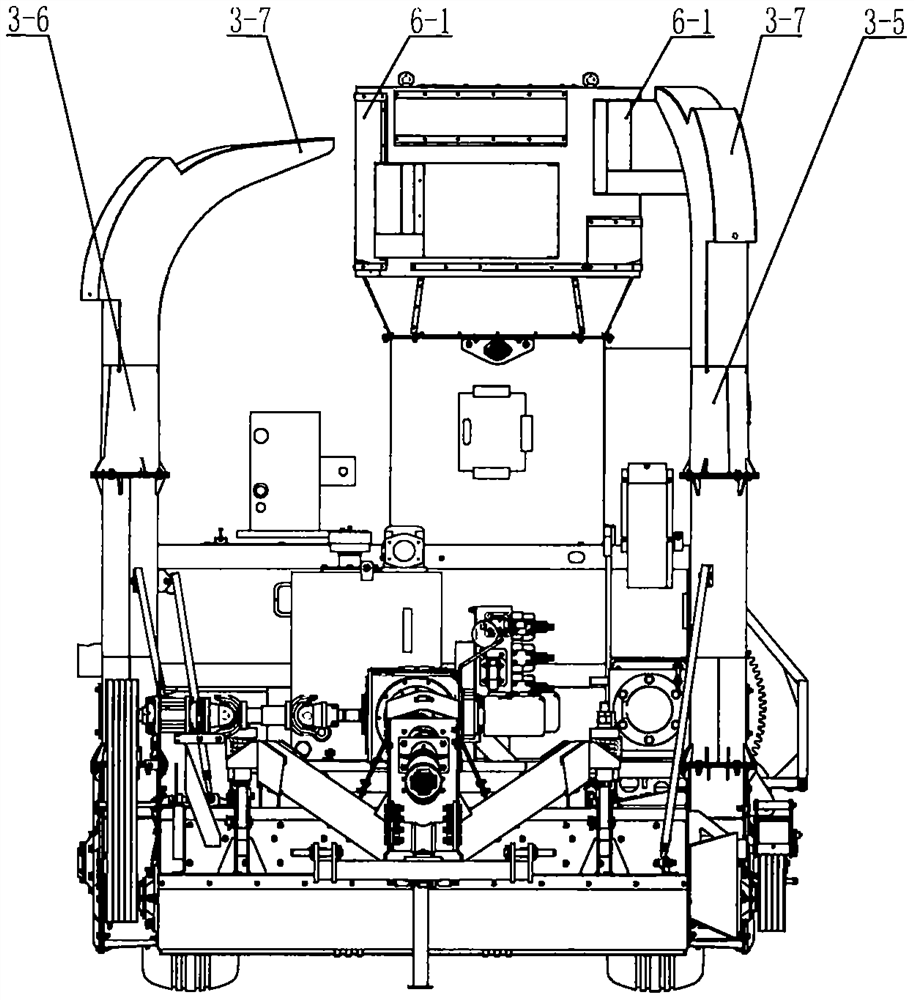

Cyperus esculentus harvest threshing, separating and cleaning system

PendingCN112056097AEasy to separateImprove liquidityThreshersAgricultural scienceAgricultural engineering

The invention discloses a cyperus esculentus harvest threshing, separating and cleaning system, and belongs to the technical field of agricultural machinery. The system comprises a frame, a threshingcylinder, a straw shaker, a cleaning fan and a transverse conveyor, the threshing cylinder is arranged at the end of one side of the frame through bolts, and the threshing cylinder comprises a threshing shaft component, an upper cover arc plate and a lower screen arc plate. The upper cover arc plate and the lower screen arc plate are fixedly connected through bolts to form a cylindrical structure,a feeding port is formed at one end, a discharging port is formed at the other end, and the threshing shaft component is arranged in the cylindrical structure. The whole set of threshing and cleaningsystem has good separability, liquidity and multiple cleaning functions through working components such as the tangential flow type threshing cylinder, a double-layer multi-stage four-box type strawshaker separation device, the cleaning fan and the transverse conveyor with the soil leakage function; and faults and problems such as winding of rhizomes, blocking of a screen and incomplete separation can be effectively prevented.

Owner:JILIN ACAD OF AGRI MACHINERY

Large-scale square banding machine

The invention provides a large-scale square banding machine. A compression chamber is internally provided with a compression plunger piston and a compression baffle which are driven by a hydraulic cylinder, a pre-compression chamber communicated with a compression chamber discharging port is arranged above the compression chamber, the pre-compression chamber is internally provided with two compression rollers driven by a hydraulic motor, a controller is combined with a hydraulic system, motion state signals are collected through various stroke switches and sensors, after the controller processes the motion state signals, a hydraulic system component is controlled to drive the compression plunger piston and the compression rollers to achieve the automatic control of banding machine compression. Compared with the compression method of a traditional large-scale square banding machine, the feeding mode is changed, and the soil content in bundled straw is reduced; the pre-compression chamber is added on the basis of an existing machine type to achieve the pre-compression deformation of the straw, thereby providing convenience for final compression forming; an electro-hydraulic automaticcontrol system replaces manual operation, thereby saving the labor, reducing the labor cost, improving the work efficiency, improving the working environment, and being capable of controlling, monitoring, alarming, and urgently stopping a machine in real time.

Owner:JILIN UNIV

Gathering type plastic film residue bundling and recovering machine

The invention discloses a gathering type plastic film residue bundling and recovering machine which comprises a machine frame. A straw breaking and returning mechanism for breaking and picking straw and stubbles in a land, a film gathering mechanism for gathering an agricultural film in the land and removing debris, a plastic film residue picking mechanism for picking plastic film residues, and abundling device for bundling the picked plastic film residues are sequentially arranged on the machine frame in the working and advancing direction. By means of the technical scheme, the straw and stubbles on the earth surface can be pulverized and returned to the field, the plastic film residues on the earth surface can be filtered and gathered on the lower side of the machine frame, the gatheredplastic film residues are picked by the plastic film residue picking mechanism and are then conveyed into a bundling machine to be bundled after debris is separated out, and therefore the recovered plastic film residues are low in soil content, the recovering effect is improved, the overall structure is simple, use is convenient, and the plastic film residue recovering effect can be greatly improved.

Owner:王洪钢

Harvester cutter head for harvesting peanuts with seedlings

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

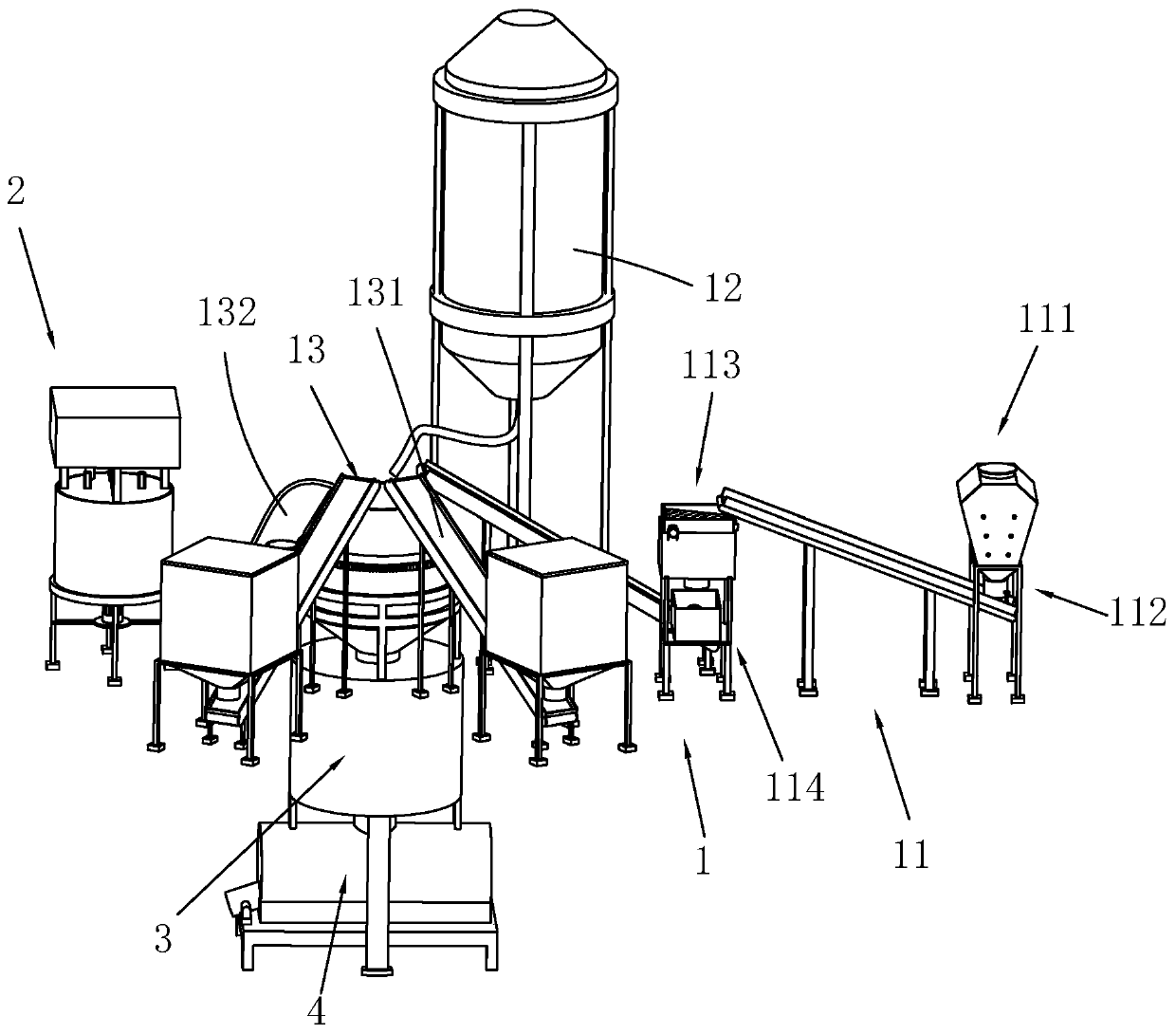

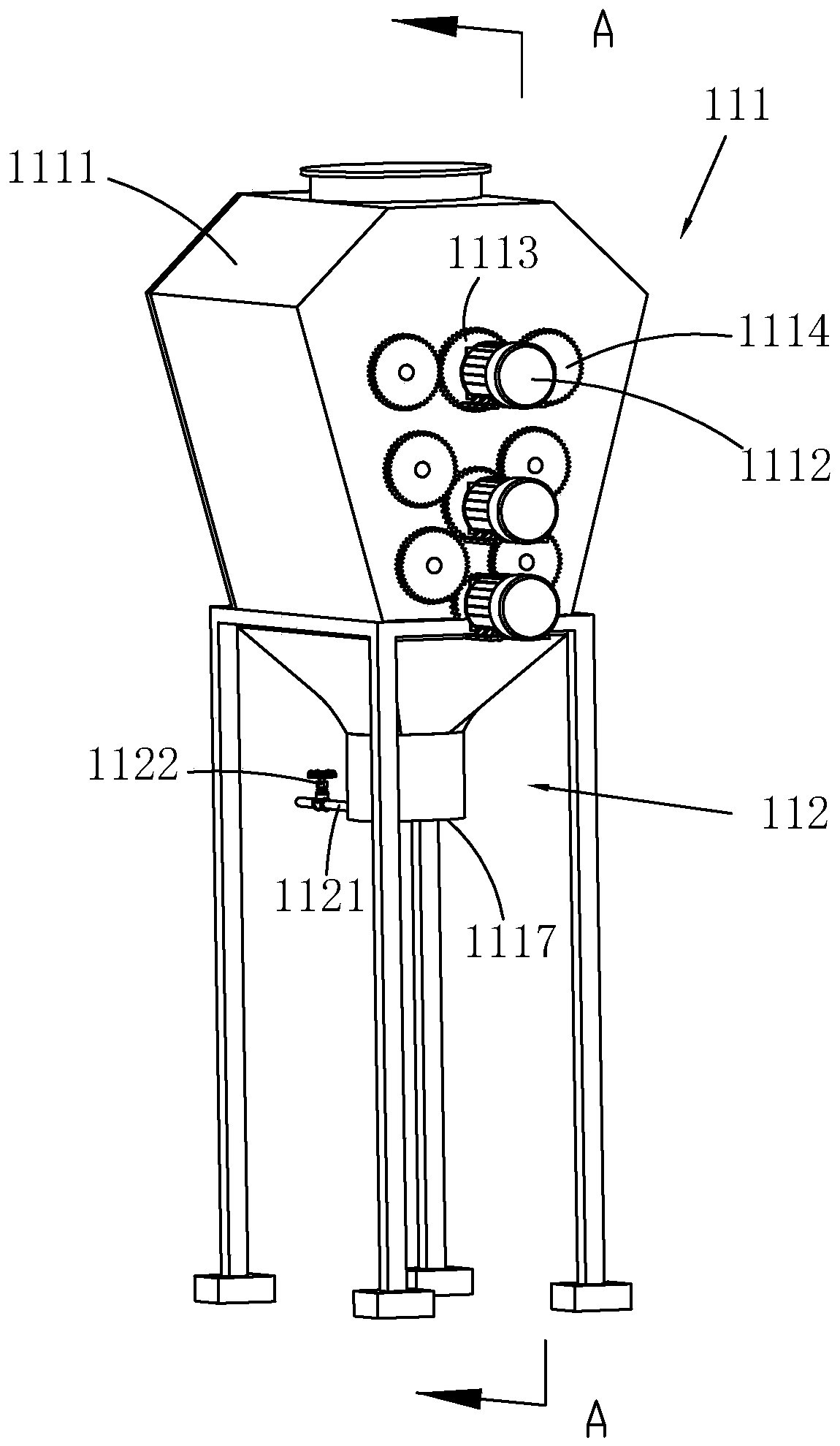

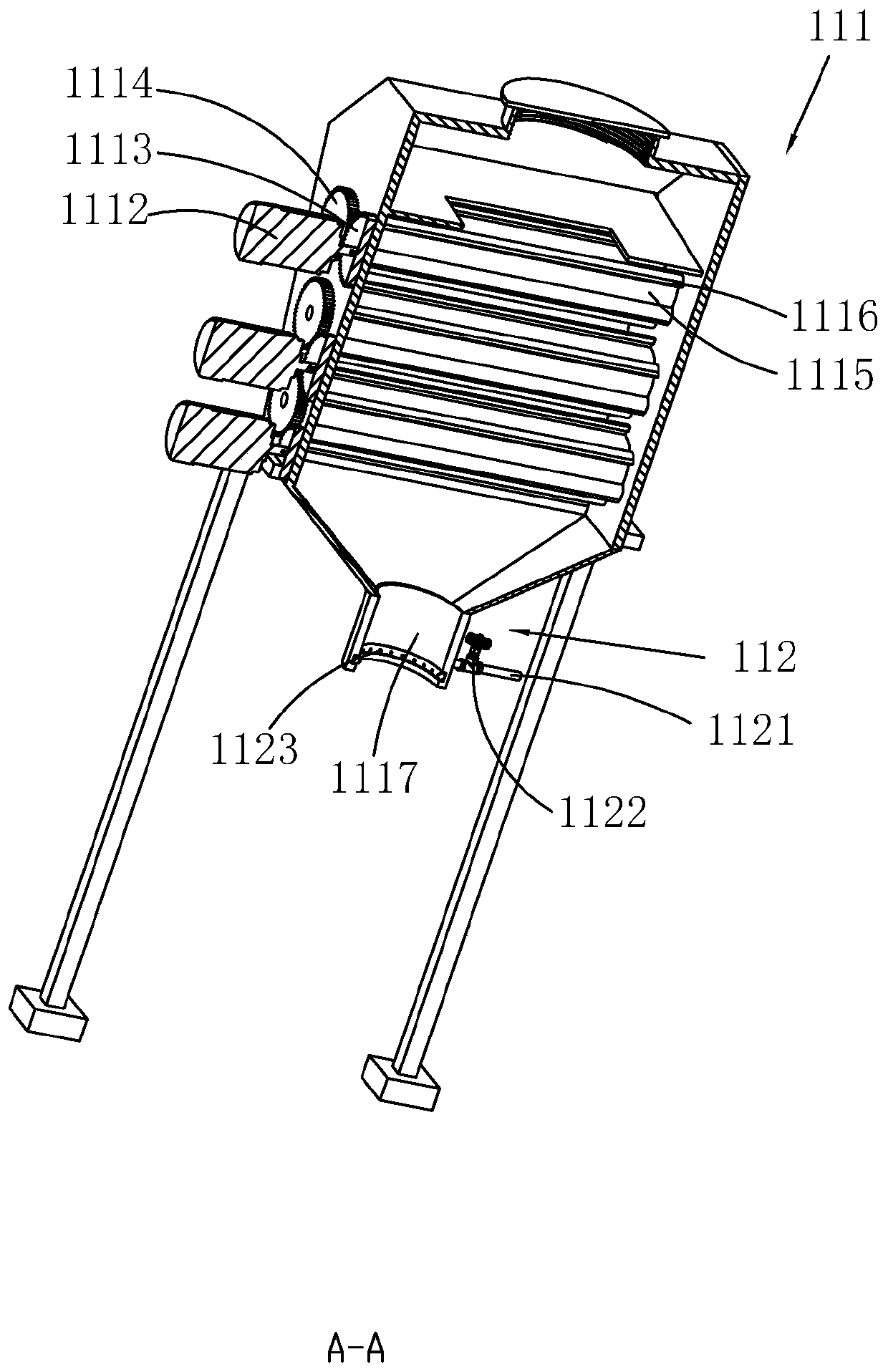

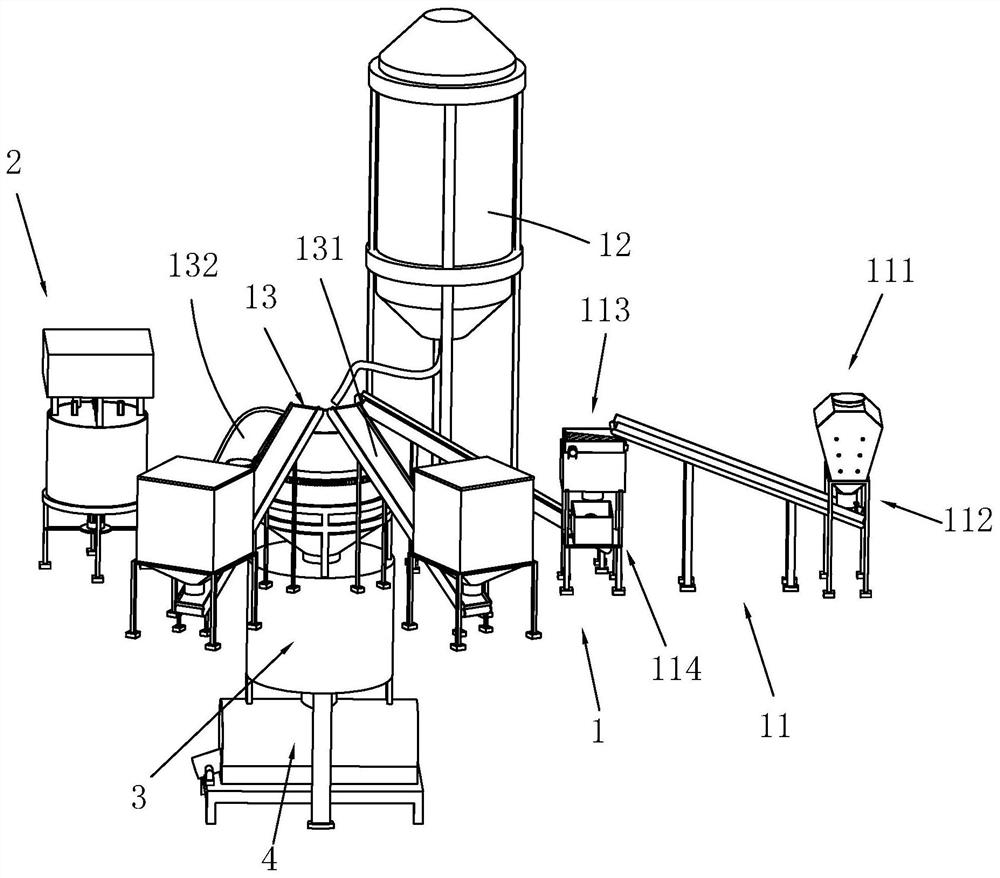

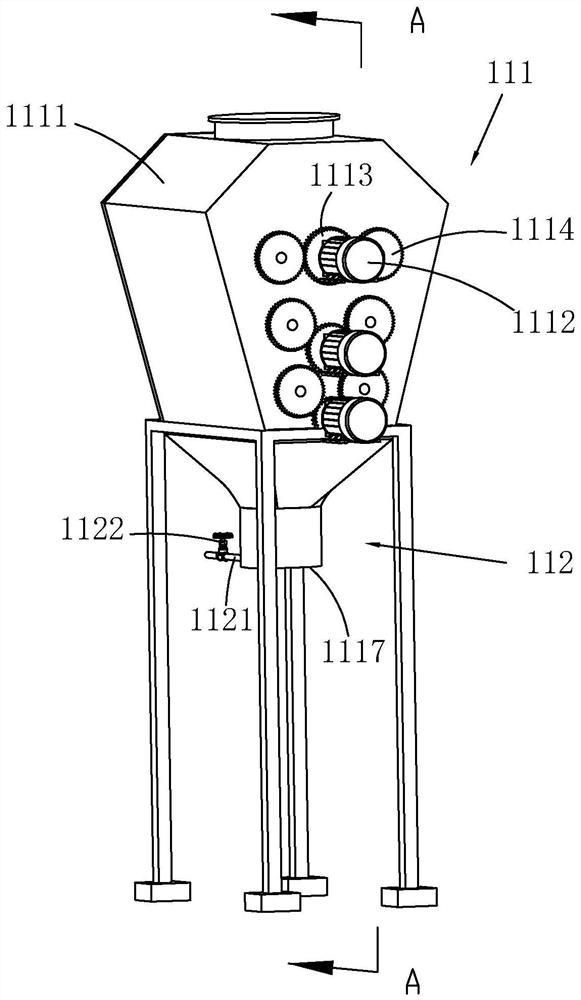

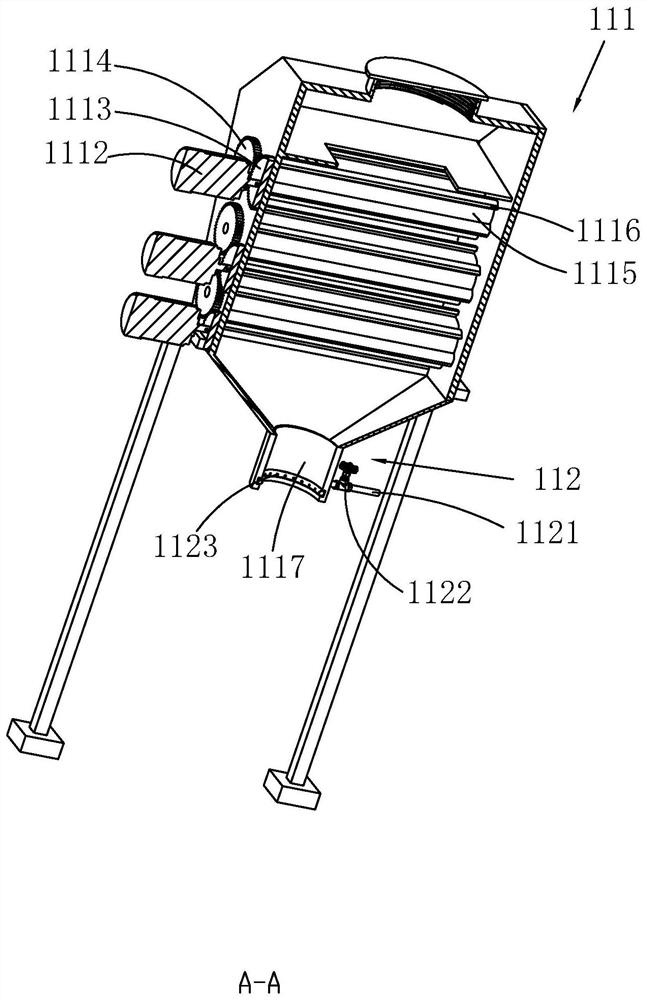

Concrete production system

ActiveCN109834843AQuality improvementIncrease profitMixing operation plantEngineeringMechanical engineering

The invention relates to a concrete production system, and belongs to the technical field of drilling equipment. The concrete production system comprises a feeding device and a stirring device. The feeding device comprises a gravel feeding device, a cement feeding device and a recycled concrete feeding device. The gravel feeding device, the cement feeding device and the recycled concrete feeding device communicates to the stirring device, a water supplying device is arranged on the stirring device, a discharging device is arranged below the stirring device. The recycled concrete feeding devicecomprises multistage smashing assemblies, a spray cleaning assembly is arranged on the lower parts of the multistage smashing assemblies, a drying and screening assembly is arranged on one side of the spray cleaning assembly, a weighing assembly is arranged on the side, away from the spray cleaning assembly, of the drying and screening assembly, and the weighing assembly is connected with the stirring device through a conveying belt. According to the concrete production system, recycled concrete is smashed, screened and reutilized, the utilization rate of raw materials is improved, and the whole quality of concrete is improved.

Owner:咸阳天力商品混凝土有限公司

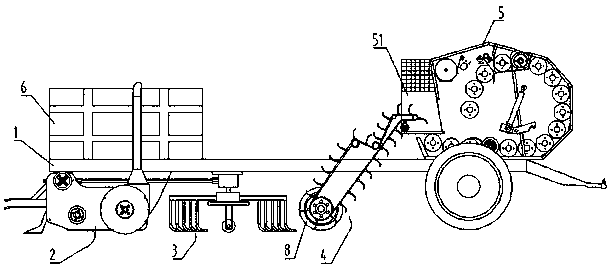

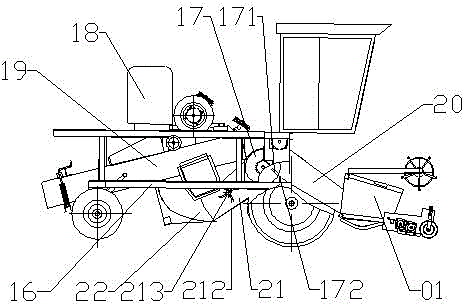

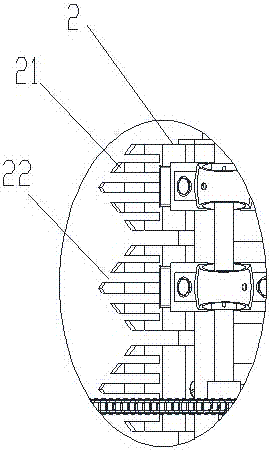

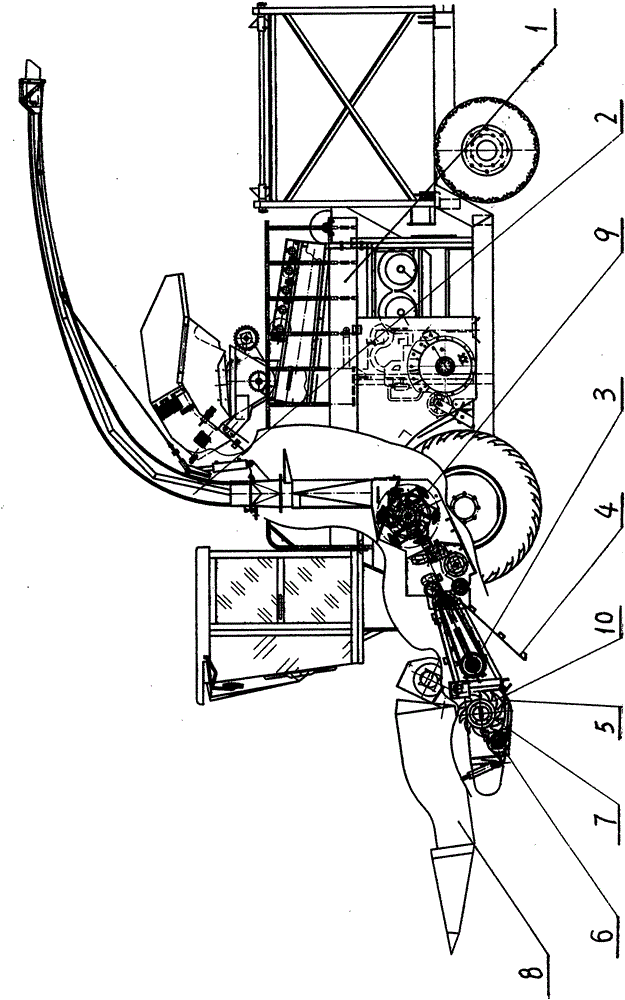

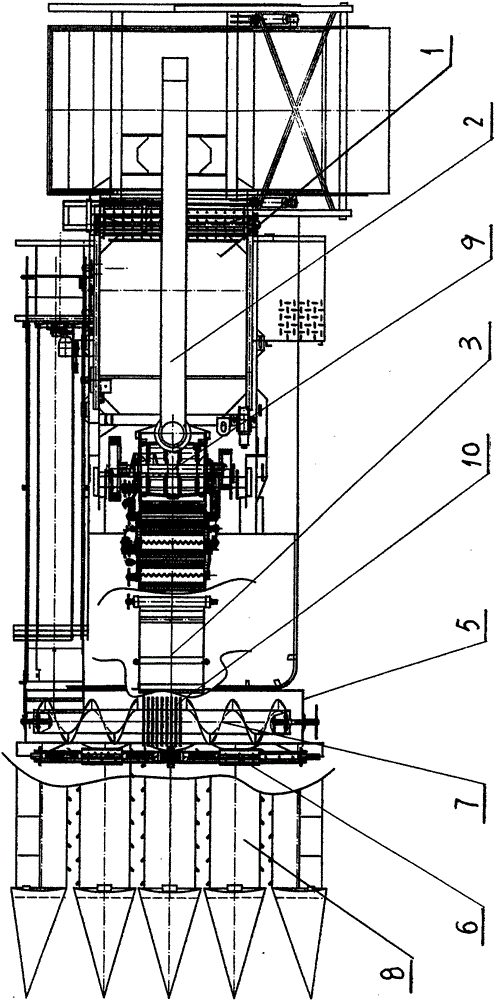

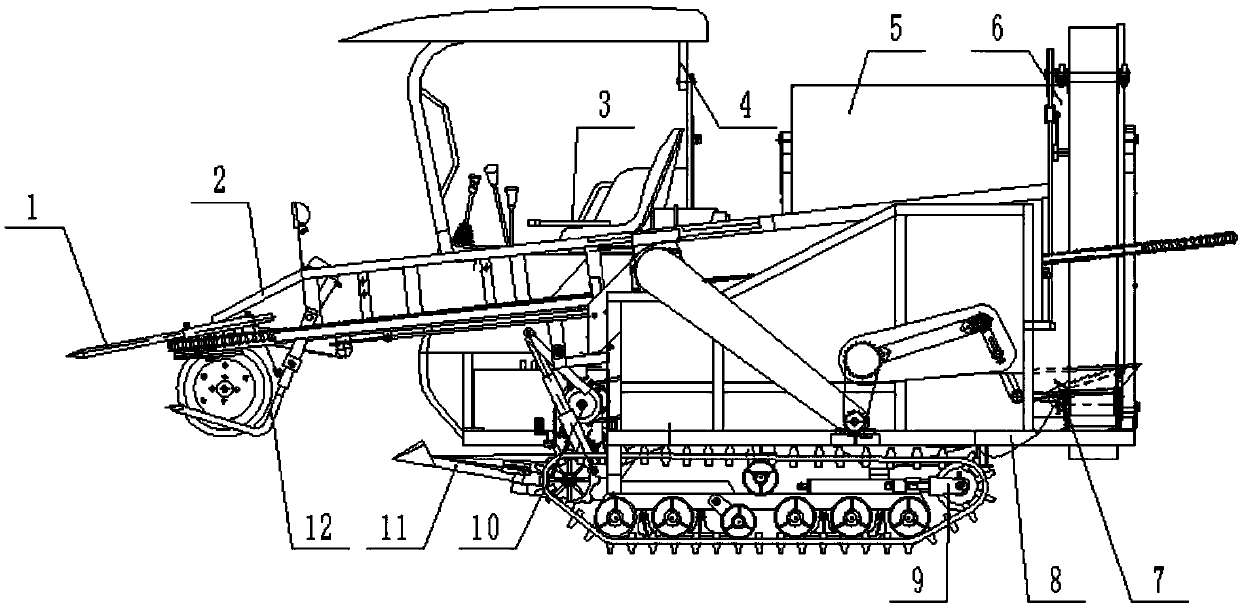

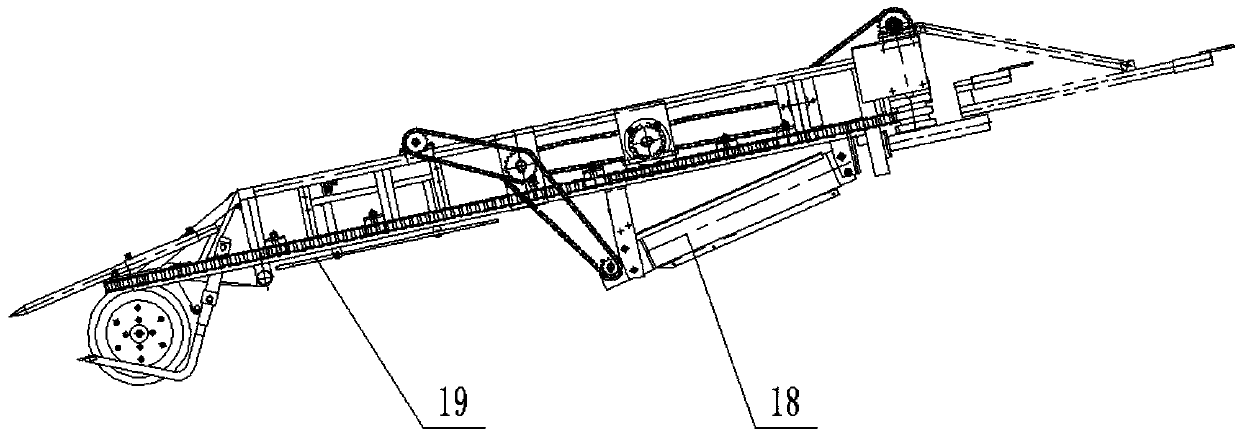

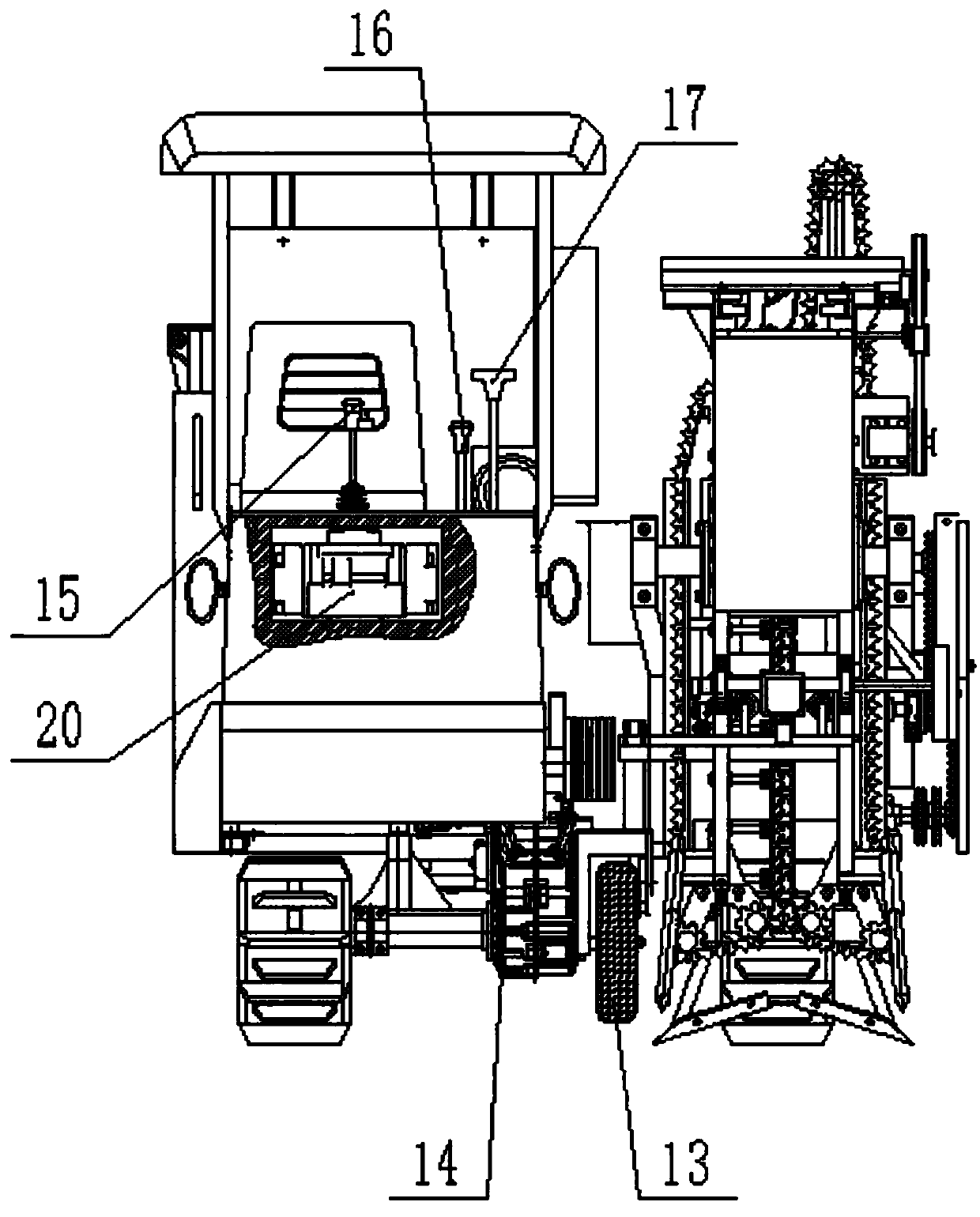

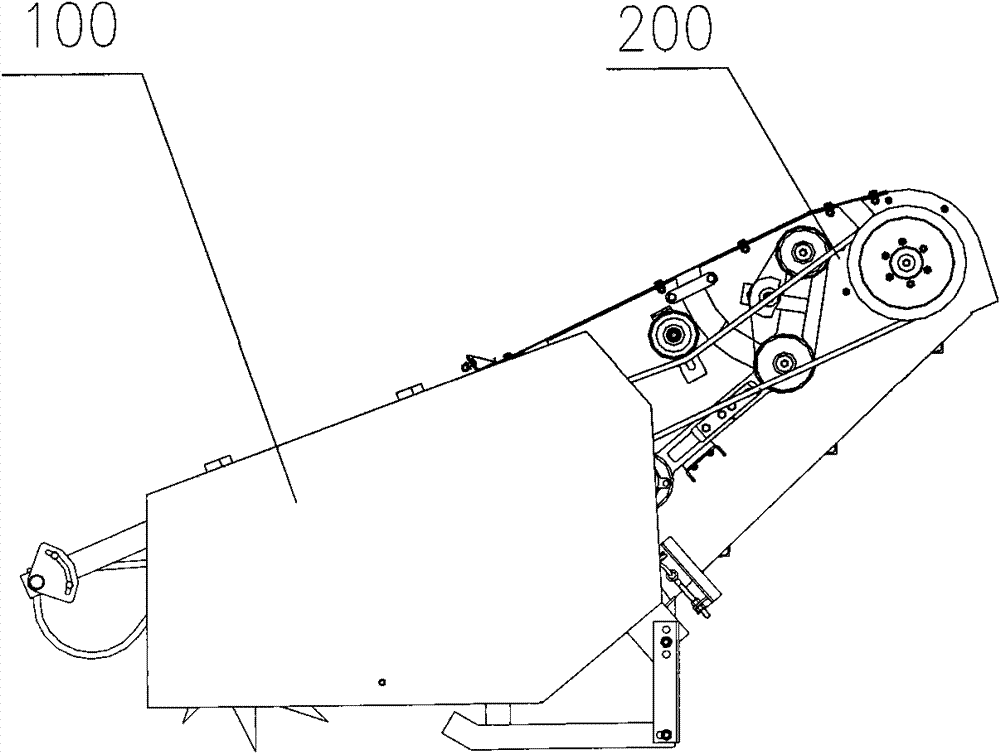

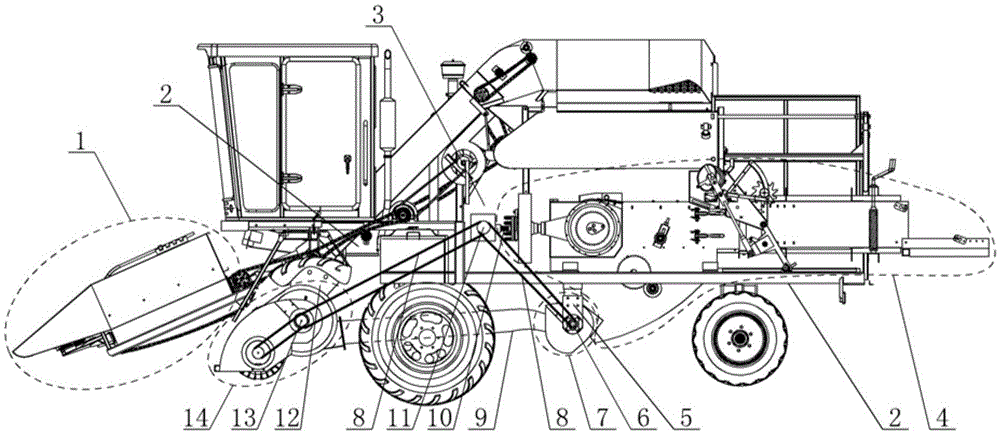

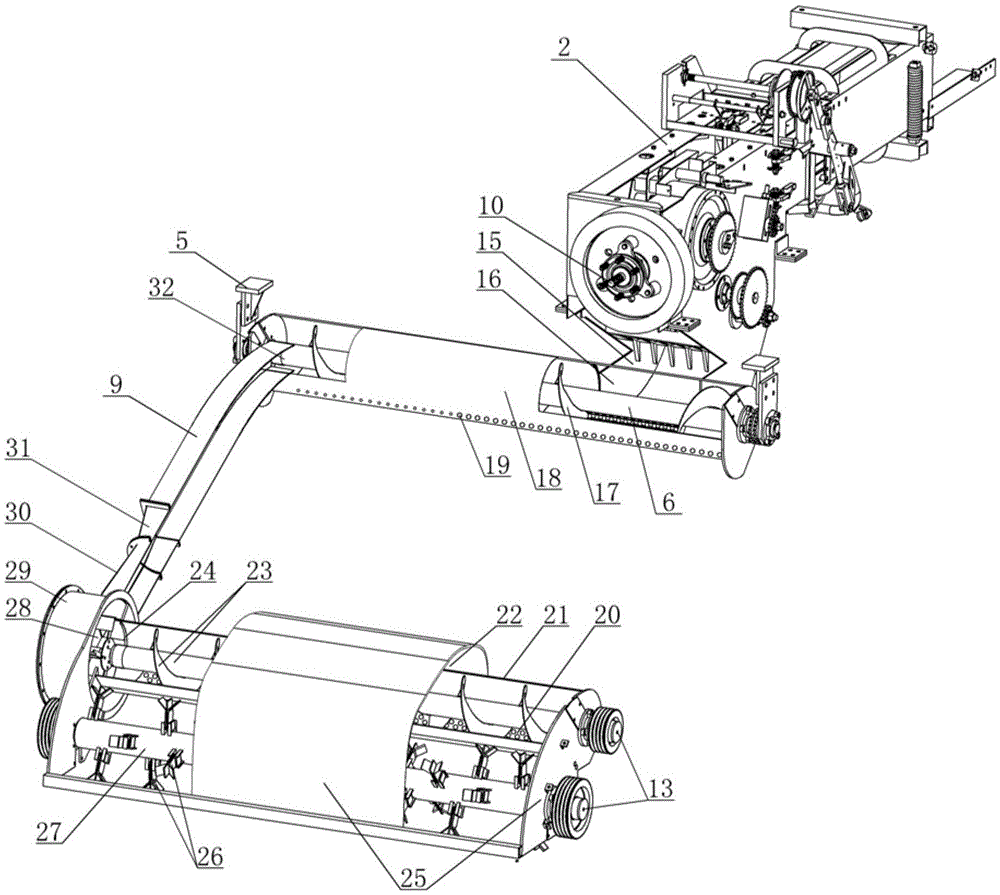

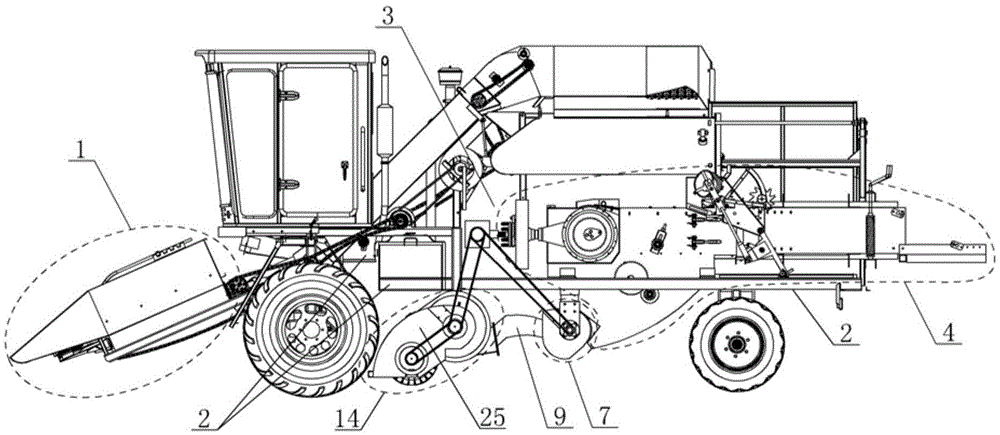

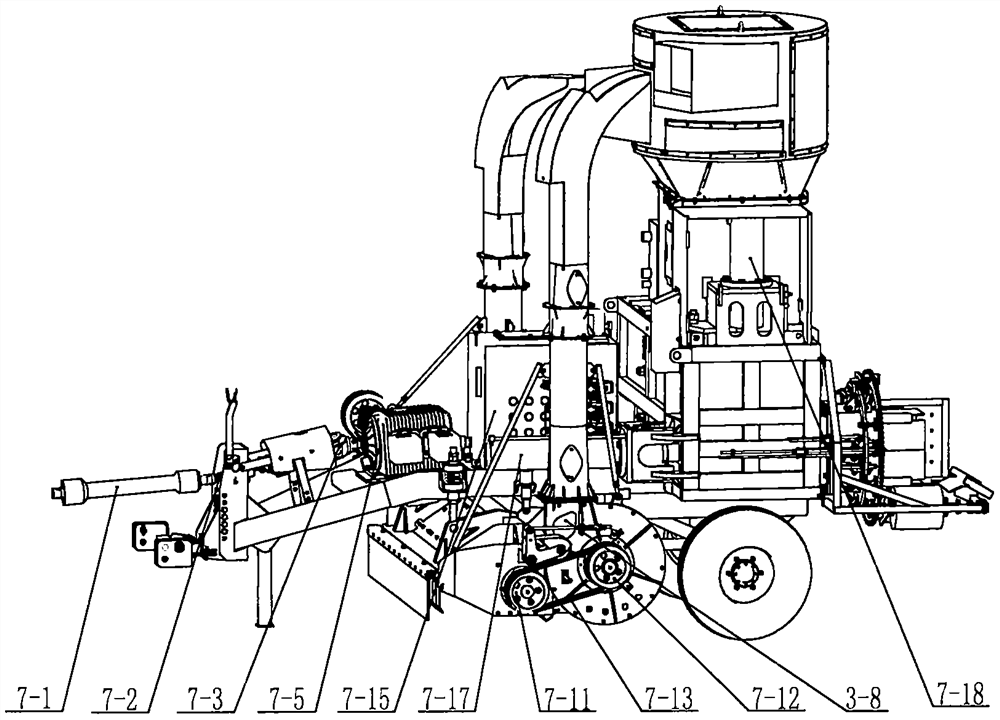

Self-propelled no-row cotton stalk combine harvesting and baling machine

ActiveCN104081927AAchieving wrong harvestImprove harvesting efficiencyReaper-bindersEngineeringInternal combustion engine

The invention relates to the field of agricultural implements, in particular to a self-propelled no-row cotton stalk combine harvesting and baling machine. The self-propelled no-row cotton stalk combine harvesting and baling machine comprises a self-propelled chassis, a no-row cotton stalk harvesting platform, a chain plate conveying device, a cutting device, a slide carriage conveying device and a baling device, wherein the no-row cotton stalk harvesting platform, the chain plate conveying device, the cutting device, the slide carriage conveying device and the baling device are successively arranged on the self-propelled chassis from front to back, and all the devices are in transmission connection with an internal combustion engine. The self-propelled no-row cotton stalk combine harvesting and baling machine can harvest cotton stalks in a no-row mode, harvesting efficiency of the cotton stalks is increased, soil contents in the cotton stalks after harvest are reduced, operation procedures of harvest of the cotton stalks are simplified, and workload is reduced.

Owner:滨州市农业机械化科学研究所

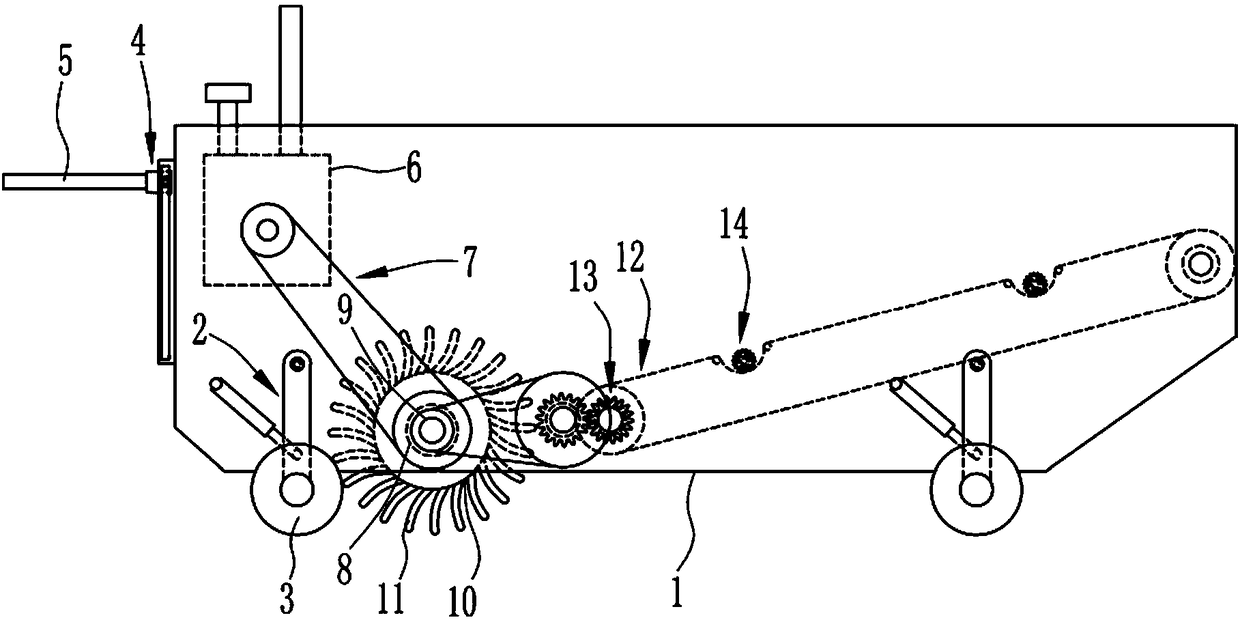

Field glume and straw pickup machine

The invention provides a field glume and straw pickup machine and belongs to agricultural machinery. The field glume and straw pickup machine comprises a rack assembly, a power transmission case, a cross flow fan impeller assembly, a screw conveyor shaft assembly and a centrifugal fan, wherein a flow guide plate and a mesh screen are mounted at the upper side part of the rack assembly sequentially from front to back and located above the cross flow fan impeller assembly and the screw conveyor shaft assembly respectively, and a cutter is mounted on a screw conveyor shaft and between the screw conveyor shaft assembly and the centrifugal fan. The field glume and straw pickup machine can be used for picking up crop glumes and crop straw, the collected glumes and straw contain little soil, are highly clean and can be directly processed into feed or biomass fuel for use, and the field glume and straw pickup machine has the characteristics of reasonable, novel and simple structure, good operation quality and high applicability.

Owner:HEIHE FANGYUAN AGRI MACHINERY TECH DEV

A concrete production system

ActiveCN109834843BQuality improvementIncrease profitMixing operation plantProcess engineeringWaste management

The invention relates to a concrete production system, and belongs to the technical field of drilling equipment. The concrete production system comprises a feeding device and a stirring device. The feeding device comprises a gravel feeding device, a cement feeding device and a recycled concrete feeding device. The gravel feeding device, the cement feeding device and the recycled concrete feeding device communicates to the stirring device, a water supplying device is arranged on the stirring device, a discharging device is arranged below the stirring device. The recycled concrete feeding devicecomprises multistage smashing assemblies, a spray cleaning assembly is arranged on the lower parts of the multistage smashing assemblies, a drying and screening assembly is arranged on one side of the spray cleaning assembly, a weighing assembly is arranged on the side, away from the spray cleaning assembly, of the drying and screening assembly, and the weighing assembly is connected with the stirring device through a conveying belt. According to the concrete production system, recycled concrete is smashed, screened and reutilized, the utilization rate of raw materials is improved, and the whole quality of concrete is improved.

Owner:咸阳天力商品混凝土有限公司

Straw cleaning and harvesting device with three cutter shafts

PendingCN112956328ARealize cutting and crushingClean thoroughlyMowersHeadersAgricultural scienceAgricultural engineering

The invention relates to a straw cleaning and harvesting device with three cutter shafts and belongs to the technical field of agriculture and husbandry machinery. The straw cleaning and harvesting device with three cutter shafts is mainly applied to different types of straws and can be used for cleaning and harvesting standing or laying straws. According to the design, straw is smashed and rubbed mainly through a front cutter shaft, a middle flail cutter shaft, a rear auger, an adjustable fixed cutter and a fixed cutter welding part, the smashed straw is cleaned through fan blades and feeding cylinders on two sides, such that a straw smashing effect and a straw rubbing effect are better, and forage is cleaner.

Owner:HUHHOT BRANCH OF CHINESE ACAD OF AGRI MECHANIZATION SCI

Sweet potato powder production process

The invention belongs to the field of food processing, and particularly relates to a sweet potato powder production process, which comprises: (1) cleaning sweet potatoes; (2) grinding the cleaned sweet potatoes into powder with a grinding machine, and adding water to dilute to obtain a sweet potato paste; (3) pumping the sweet potato paste into a first filter with a pump to separate; (4) pumping the filtered filtrate in the step (3) into a second filter to filter, and pumping the obtained filtrate into a precipitation tank; and (5) adding a saturated sweet potato powder solution to the precipitation tank, stirring, carrying out precipitation, pumping the water on the upper layer out after completing the precipitation, taking the sweet potato starch, drying, and bagging. According to the present invention, multi-time washing is performed so as to reduce the soil content in the sweet potato powder, the fermented saturated sweet potato powder solution is adopted to carry out precipitation so as to reduce the required precipitation time and increase the powder yield, and other chemical substances are not required to be added to the sweet potato powder so as to improve the taste and the nutritional value of the sweet potato powder.

Owner:YINGSHANG TIANHAO FOOD

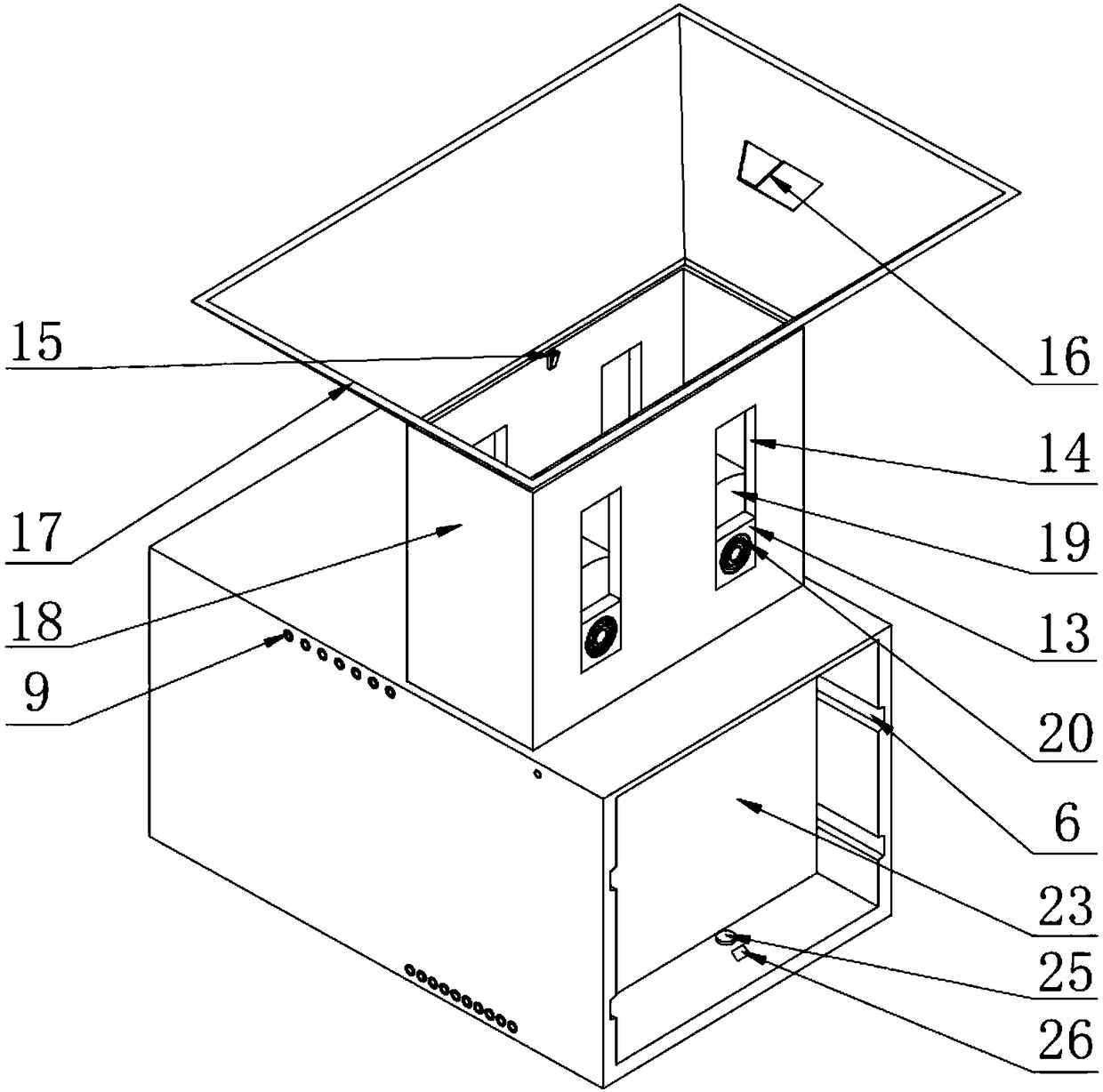

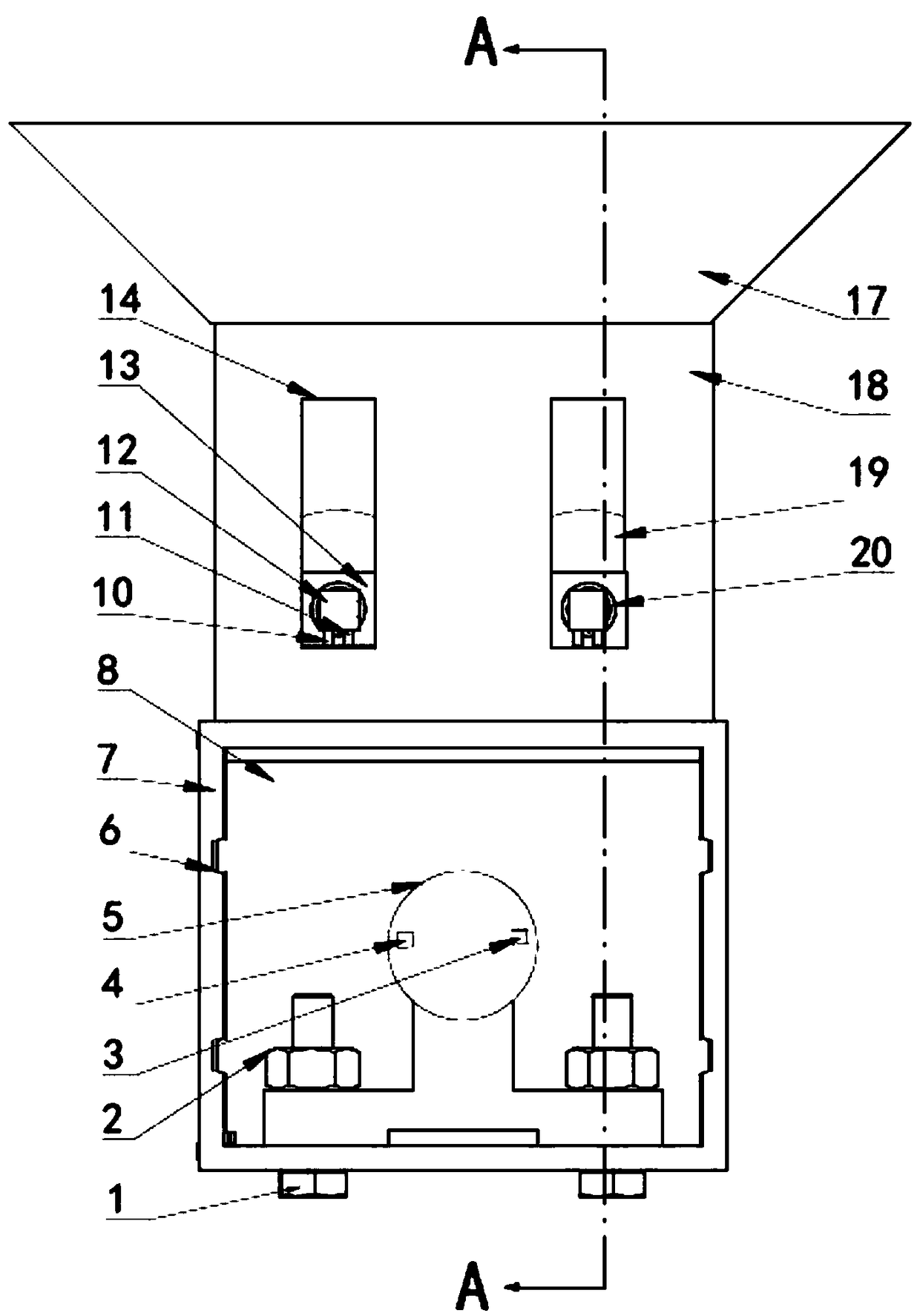

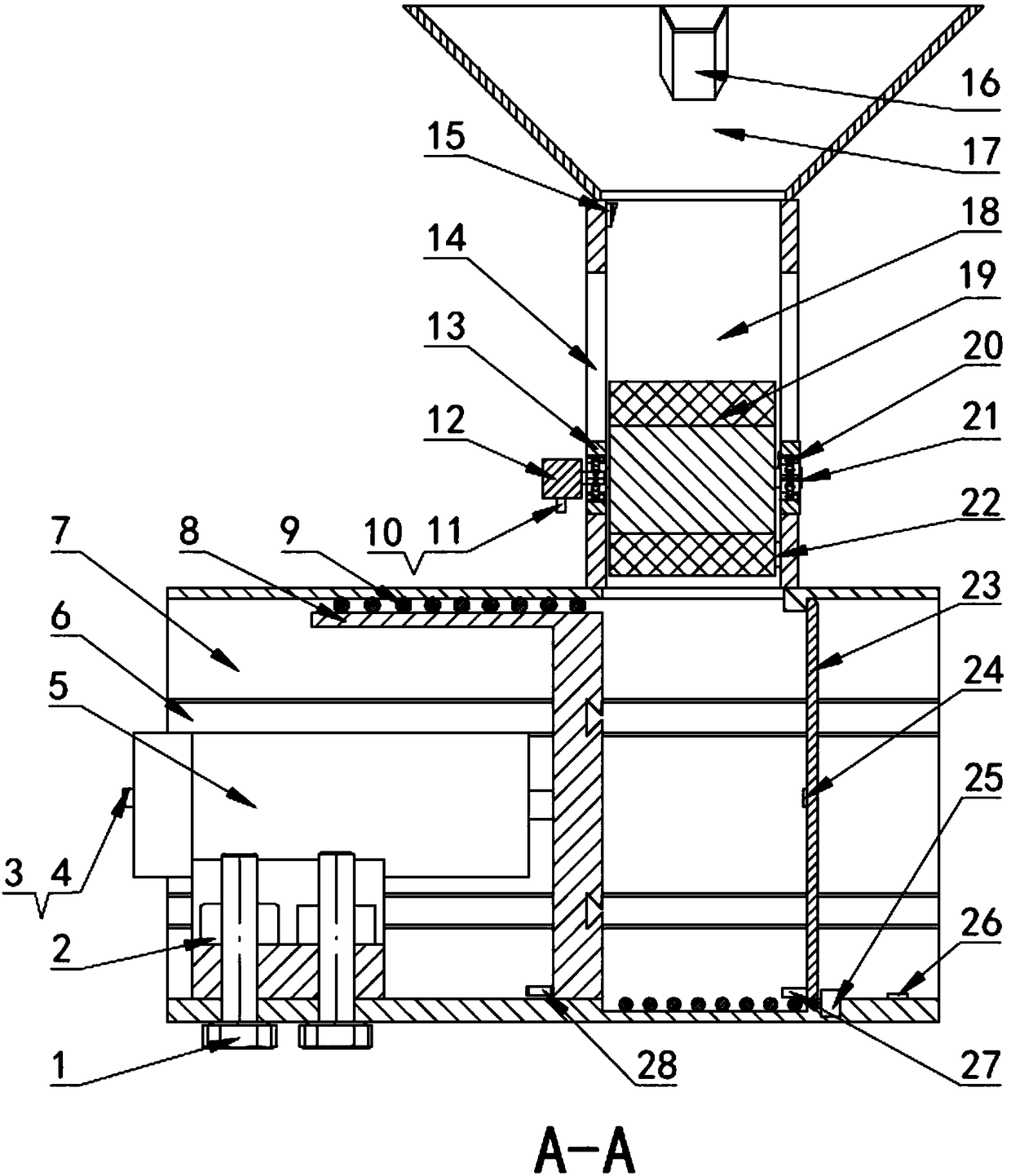

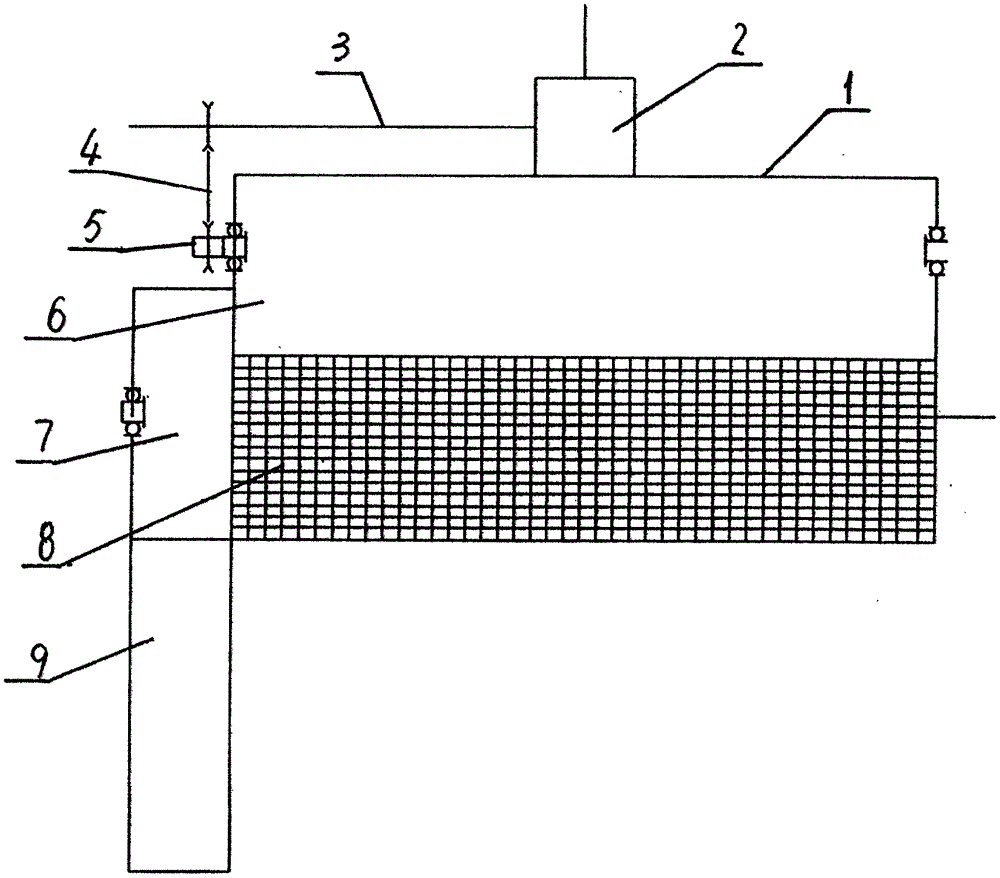

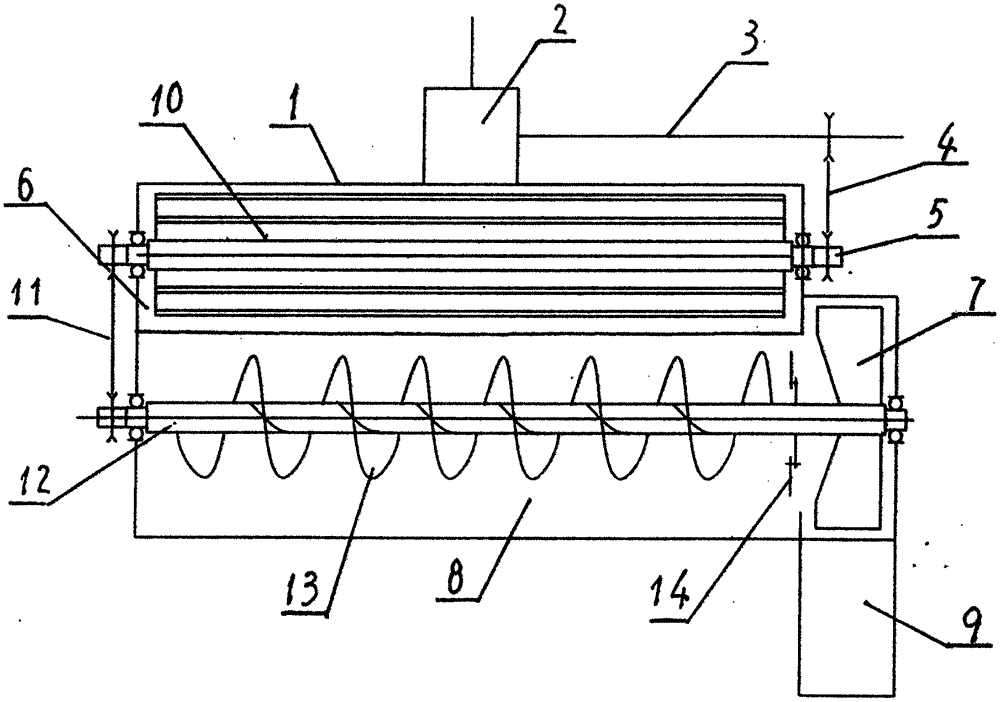

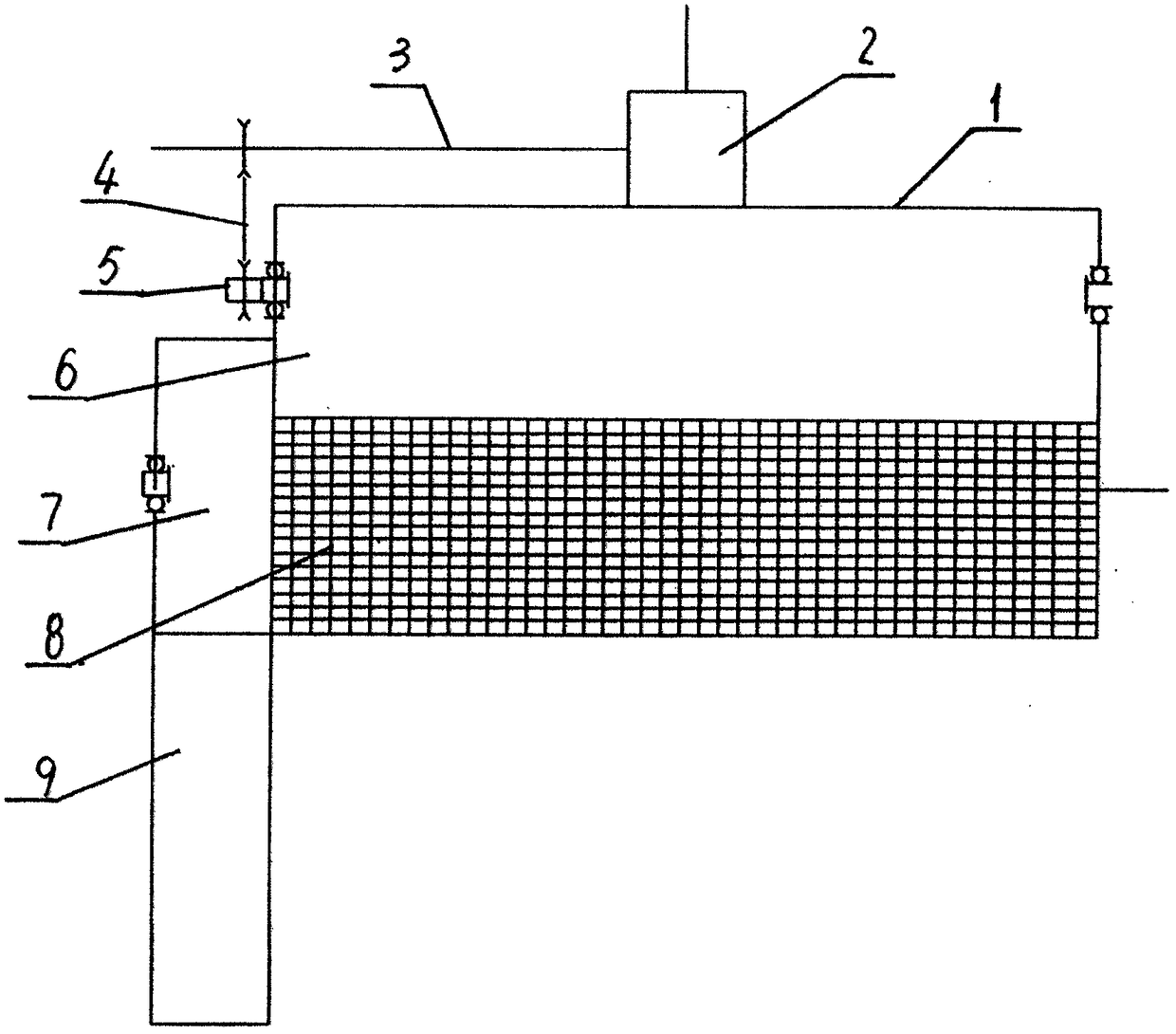

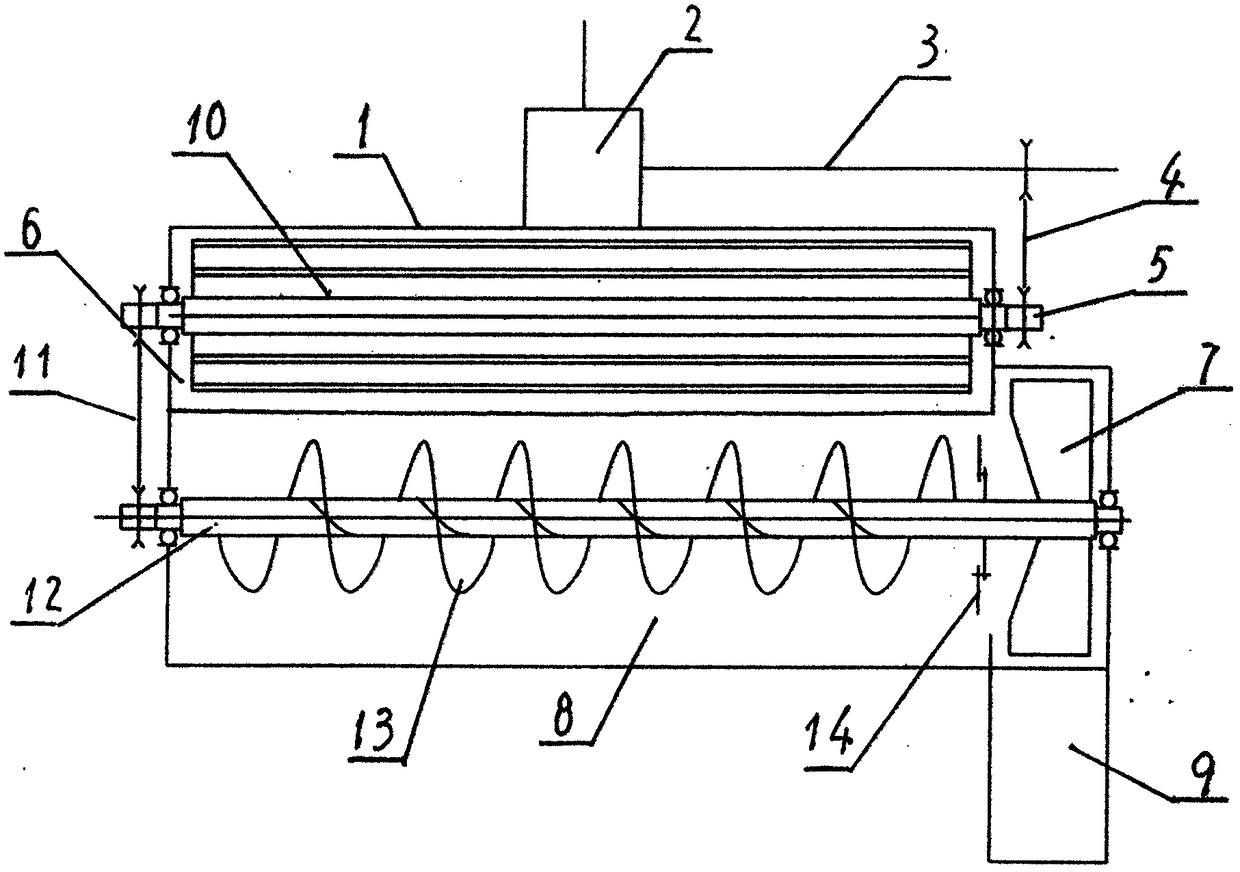

Equipment suitable for coal simple cleaning

PendingCN110449396AReduce soil contentHigh calorific valueCleaning using liquidsElectric machineryEngineering

The invention relates to equipment suitable for coal simple cleaning. The equipment suitable for the coal simple cleaning comprises a cleaning barrel, a front support, a rear positioning frame, a machine switch, a cleaning motor, a reduction gear box, a reduction gear box maintenance window hole, a rear transmission base, a lighting equipment support, an explosion-proof lighting lamp, a clean coaloutlet, a filtering water tank, a filtering water tank maintenance window, a water supply motor and a water pump; the front support is welded and connected with the cleaning barrel; the clean coal outlet is welded at one end of the cleaning barrel; the one side surface of the cleaning barrel is welded and connected with the rear positioning frame; the machine switch is mounted on the surface of the positioning frame through screws; the lighting equipment support is mounted on the one side surface of the positioning frame; the explosion-proof lighting lamp is fixed on the surface of the lighting equipment support through screws; the rear transmission base is welded and connected with the surface of the rear positioning frame; the reduction gear box is mounted on the surface of the transmission base; the reduction gear box is connected with the cleaning motor through a bearing; and coal just produced can be simply cleaned to reduce the content of mud and coal dust in the coal.

Owner:徐州市恩矿新材料有限公司

Peanut crushed soil seedling device

ActiveCN104067762BAvoid congestionImprove cleanlinessDigger harvestersSlide platePulp and paper industry

The invention provides an extensible tooth type soil pulverizing and seedling shifting device for peanuts. The soil pulverizing and seedling shifting device comprises a roller, a rotating main shaft, extensible teeth, a roller fixing disk, an extensible tooth fixed device and an extensible tooth moving device; the roller fixing disk, the extensible tooth fixed device and the extensible tooth moving device penetrate the rotating main shaft; the rotating main shaft is arranged in the center of the roller and connected with a power device through a driving chain wheel; the surface of the roller is provided with through holes; one end of every extensible tooth is arranged inside the roller and the other end of the extensible tooth is arranged outside the roller through the corresponding through hole; the periphery of the roller fixing disk is fixedly connected with the roller through bolts. The extensible tooth type soil pulverizing and seedling shifting device for peanuts is arranged at the front end of a conveyor device and accordingly clods after crop digging can be broken and accordingly the clods can be refined, the clods in the conveying process can be reduced, and the blocking of a fruit picking device is prevented; meanwhile the cleaning is convenient and the soil containing rate after harvest is reduced; peanut seedlings are directly shifted to a rear sliding plate after the soil pulverizing is achieved so as to fall onto the conveyor device and accordingly the width of the conveyor device is reduced.

Owner:QINGDAO AGRI UNIV

Process for regenerating plastic woven bag by utilizing waste plastics

InactiveCN112537086AImprove product qualitySimple structureBag making operationsPaper-makingAcetic acidEthylic acid

The invention relates to a process for regenerating a plastic woven bag by utilizing waste plastics. The process for regenerating the plastic woven bag by utilizing the waste plastics comprises the following steps: putting the waste plastics in an ultrasonic environment in advance; pre-cleaning soil on the surfaces of the waste plastics by using ultrasonic waves; performing shearing after the cleaning is completed; and putting the sheared material into a cleaning solution containing hydrochloric acid and acetic acid, so that acetic acid and hydrochloric acid in the cleaning solution can reactwith the soil on the surfaces of the waste plastics after being diluted, calcium carbonate in the soil is corroded, and the surfaces of the waste plastics are further cleaned; and therefore, the content of soil mixed into the waste plastics during production of the plastic woven bag is reduced, and the production quality of the plastic woven bag is improved.

Owner:安徽聚屹新材料科技有限公司

Potato digging and harvesting device

ActiveCN105230217BReduce the stress areaImprove performance in soilDiggersAgricultural engineeringShovel

The invention provides a potato digging and harvesting device, which includes a frame, a gearbox arranged on the frame, and a digging shovel for digging potatoes. A connecting frame is connected to the digging shovel; a power output shaft of the gearbox is connected to a The eccentric wheel that moves eccentrically under the action of power, the part that deviates from the center of the eccentric wheel is connected with the connecting frame through the connecting screw. When the eccentric wheel moves eccentrically, it drives the excavating shovel to make a circular motion to loosen the soil to be excavated; the excavating shovel includes a shovel body , The shovel body is provided with a plurality of openings at intervals, forming a grid shape, so as to reduce the force-bearing area of the shovel body. The device reduces the force-bearing area of the shovel body by setting the grid-shaped shovel body, improves the soil penetration ability of the shovel body, and improves work efficiency.

Owner:QINGDAO AGRI UNIV

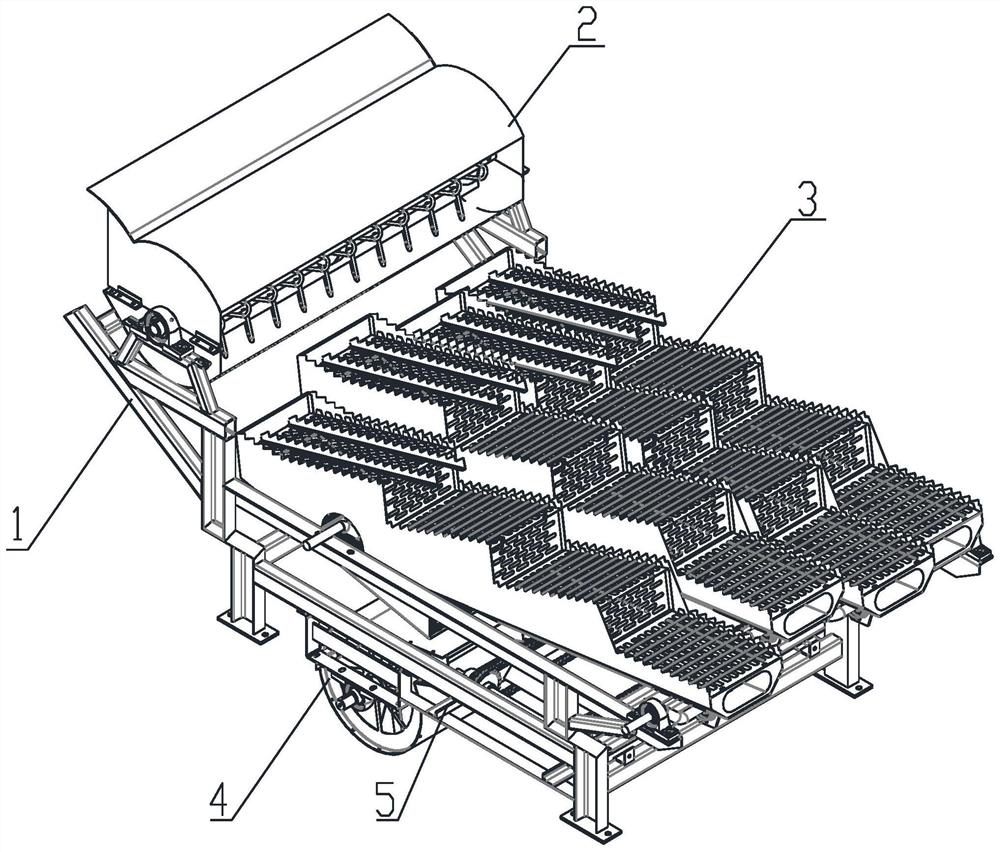

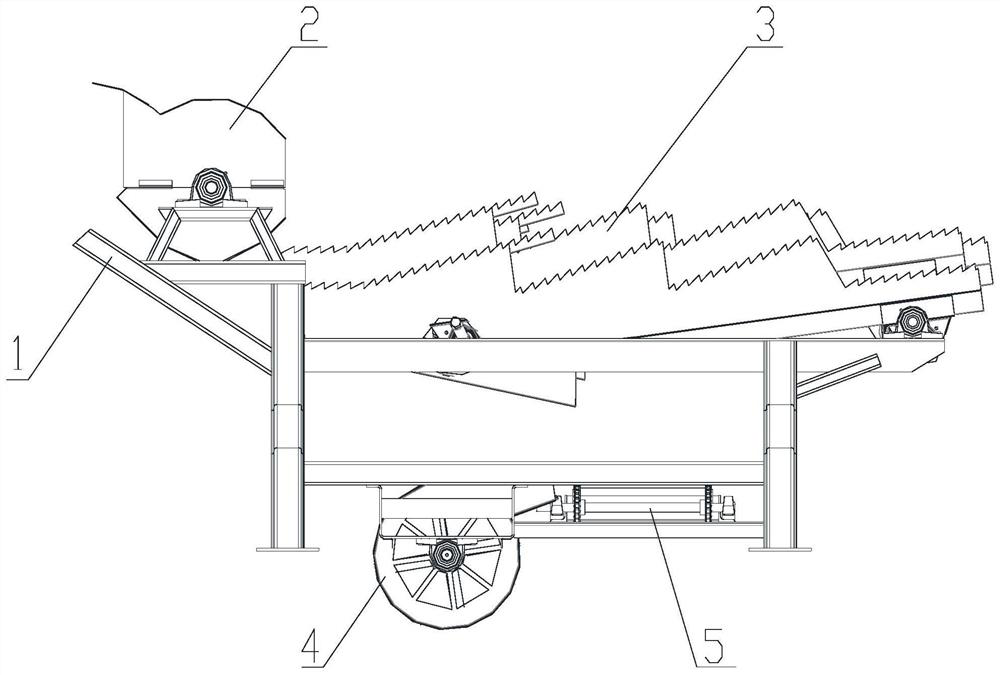

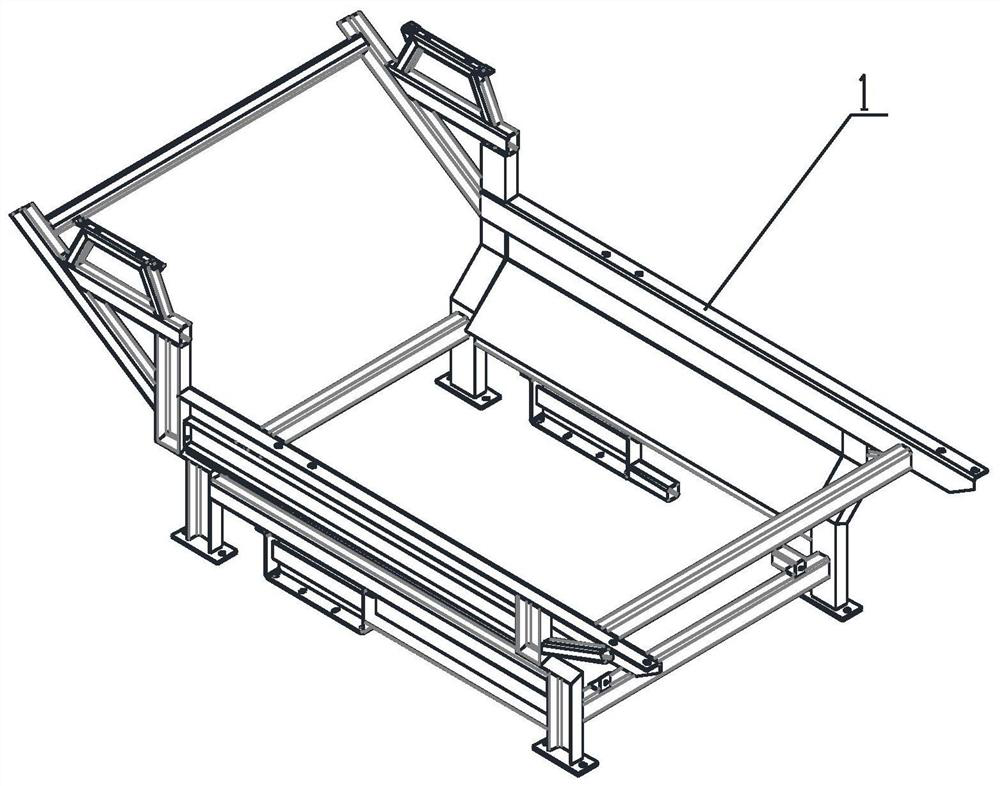

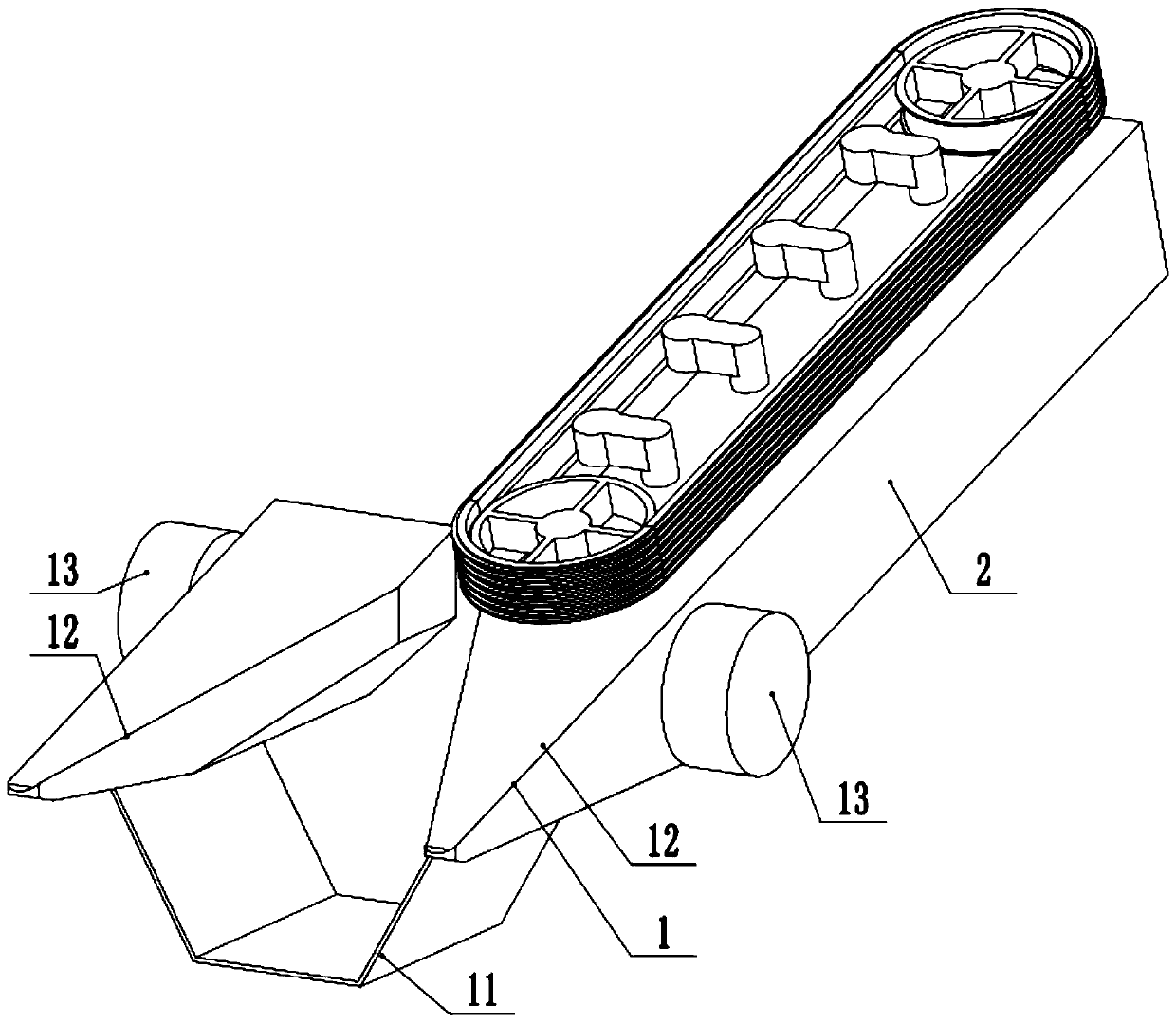

Rod chain and side backward inclined vibrating screen combined residual film recovery machine

ActiveCN110024516AReduce separation loadReduce soil contentSievingScreeningEngineeringMechanical engineering

The invention relates to a rod chain and side backward inclined vibrating screen combined residual film recovery machine. A front film-soil separation mechanism and a rear film-soil separation mechanism are arranged front and back to finish film-soil separation operation in sequence, film-soil separation operation efficiency can be improved remarkably, and the soil content of residual films in a film collecting basket is reduced; the front film-soil separation mechanism is provided with a conveying belt assembly; the conveying belt assembly is provided with a plurality of front discharging gaps through which soil can pass; the rear film-soil separation mechanism is provided with an inner screen frame and a vibrating screen frame, and side shielding plates are arranged on the left side andthe right side of the vibrating screen frame separately; a plurality of saw-toothed screen pieces are arranged on the upper side of the inner screen frame, and the vibrating screen frame is obliquelyarranged front and back; the inner screen frame is inclined upwards relative to the vibrating screen frame such that a screen surface has a lowermost end facing a side discharge opening of one of theside shielding plates. Large-block soil can be discharged from the side soil discharge openings and cannot enter the film collecting basket.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Machine-made sand processing process

ActiveCN102806133BLow stone dust contentReduce soil contentGrain treatmentsCrushed stoneProcess engineering

The invention discloses a machine-made sand processing process, which comprises the following processes that stone materials enter a jaw crusher to be decomposed into stone blocks not greater than 350mm, and then, the stone blocks enter a reverse smashing machine; the stone blocks are crushed into crush stones by the reverse smashing machine, the crushed stone enters a primary vibration sieve to be screened, the crushed stones smaller than 31.5mm enter an impact type crusher, and the crushed stones greater than 31.5mm return the reverse smashing machine to be crushed; after entering the impact type crusher to be crushed, the crushed stones enter a two-grade vibration sieve to be screened, and sand smaller than 3mm enters a sand washing machine; sand greater than 3 to 5mm enters an efficient fine crushing machine to be made into sand smaller than 3mm, and the sand smaller 3mm enters the sand washing machine after entering two-grade vibration sieve to be screened; the crushed stones greater than 5mm enter a three-grade vibration sieve; the crushed stones are screened into the crushed stones in three grades by the three-grade vibration sieve, and the crushed stones are used for material discharge in the vibration sieve after being flushed by water. The machine-made sand produced by the process provided by the invention has the advantages that each index can respectively meet the technical index of high-performance on machine-made sand, and the product quality is high, and stability and reliability are realized.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

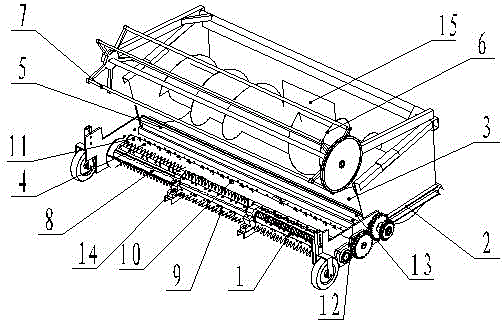

A pick-up device and a collection device using the pick-up device

ActiveCN113273389BReduce soil contentReduced Power RequirementsLoadersAgricultural scienceAgricultural engineering

Owner:哈尔滨科罗得农业装备开发有限公司

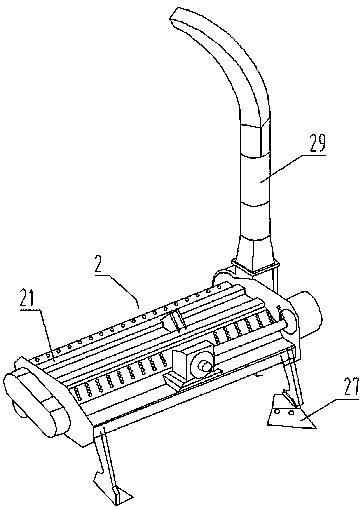

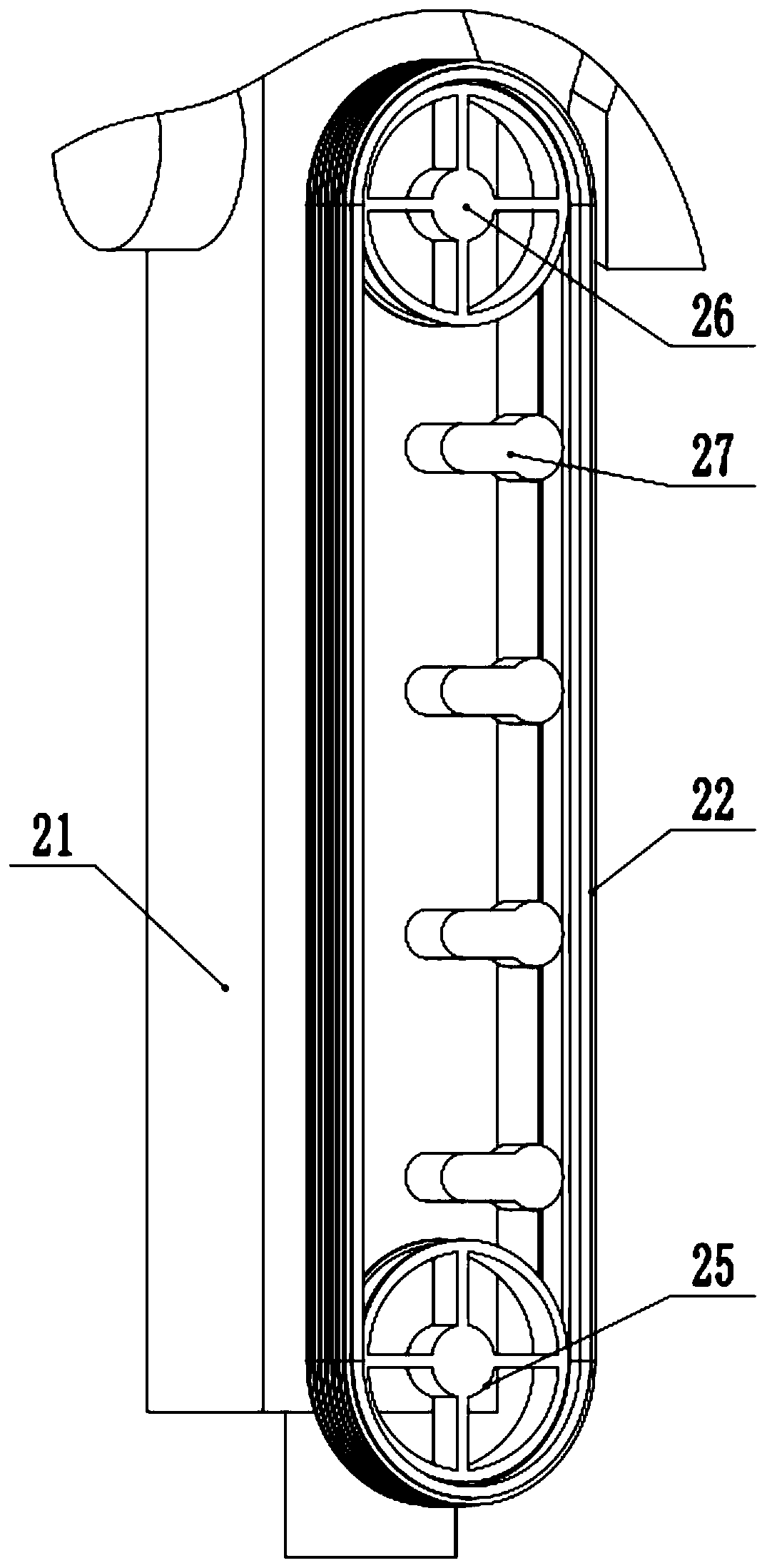

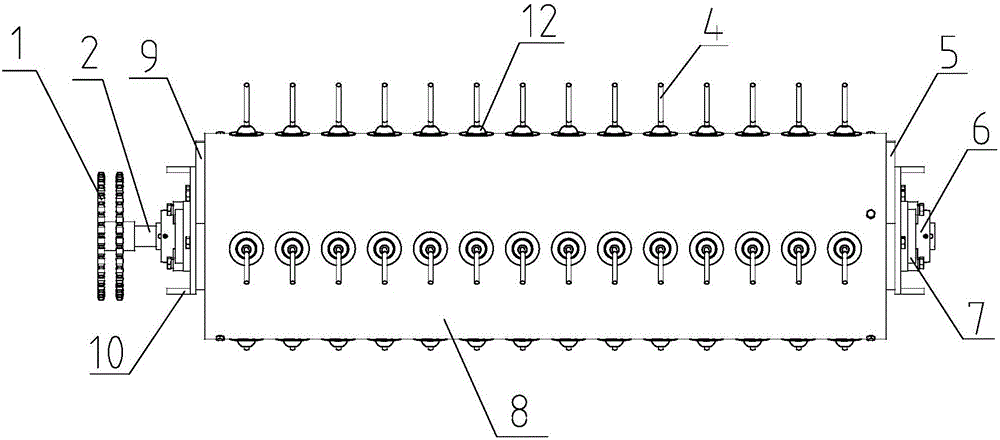

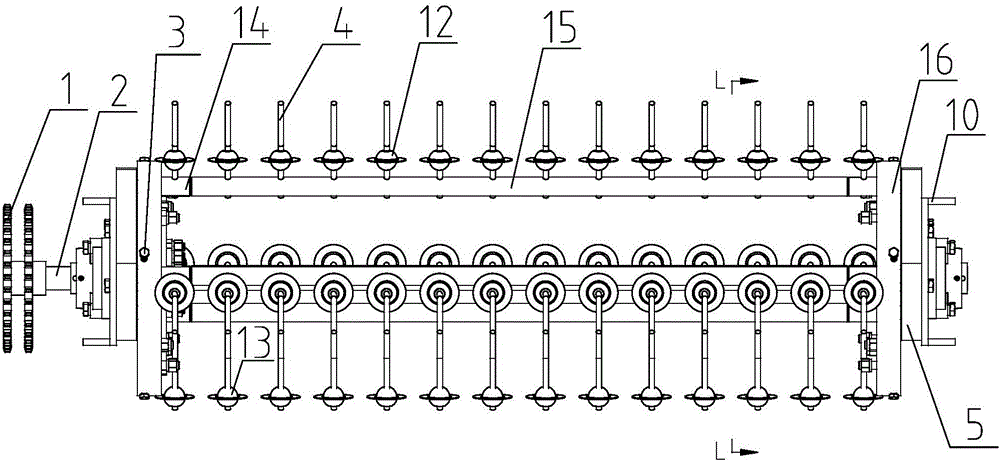

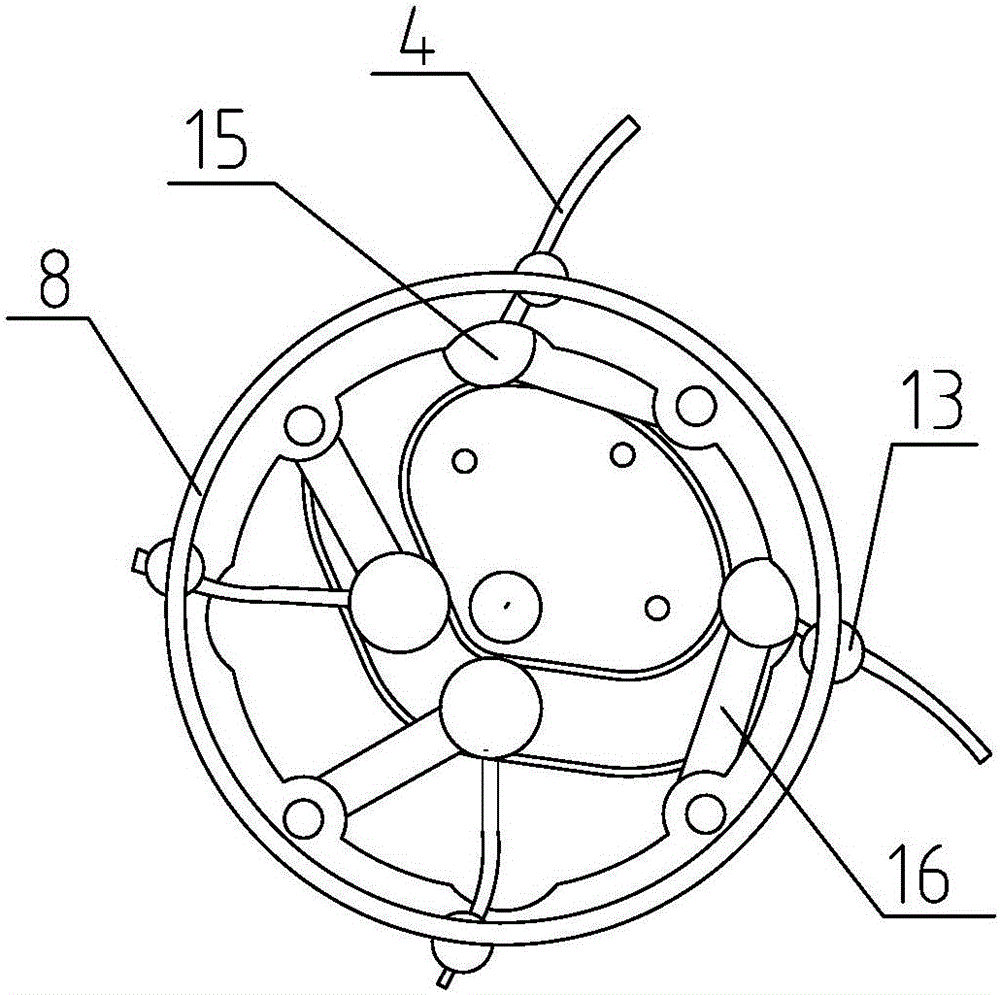

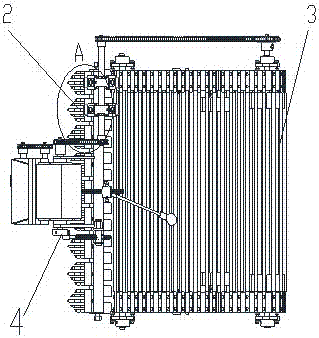

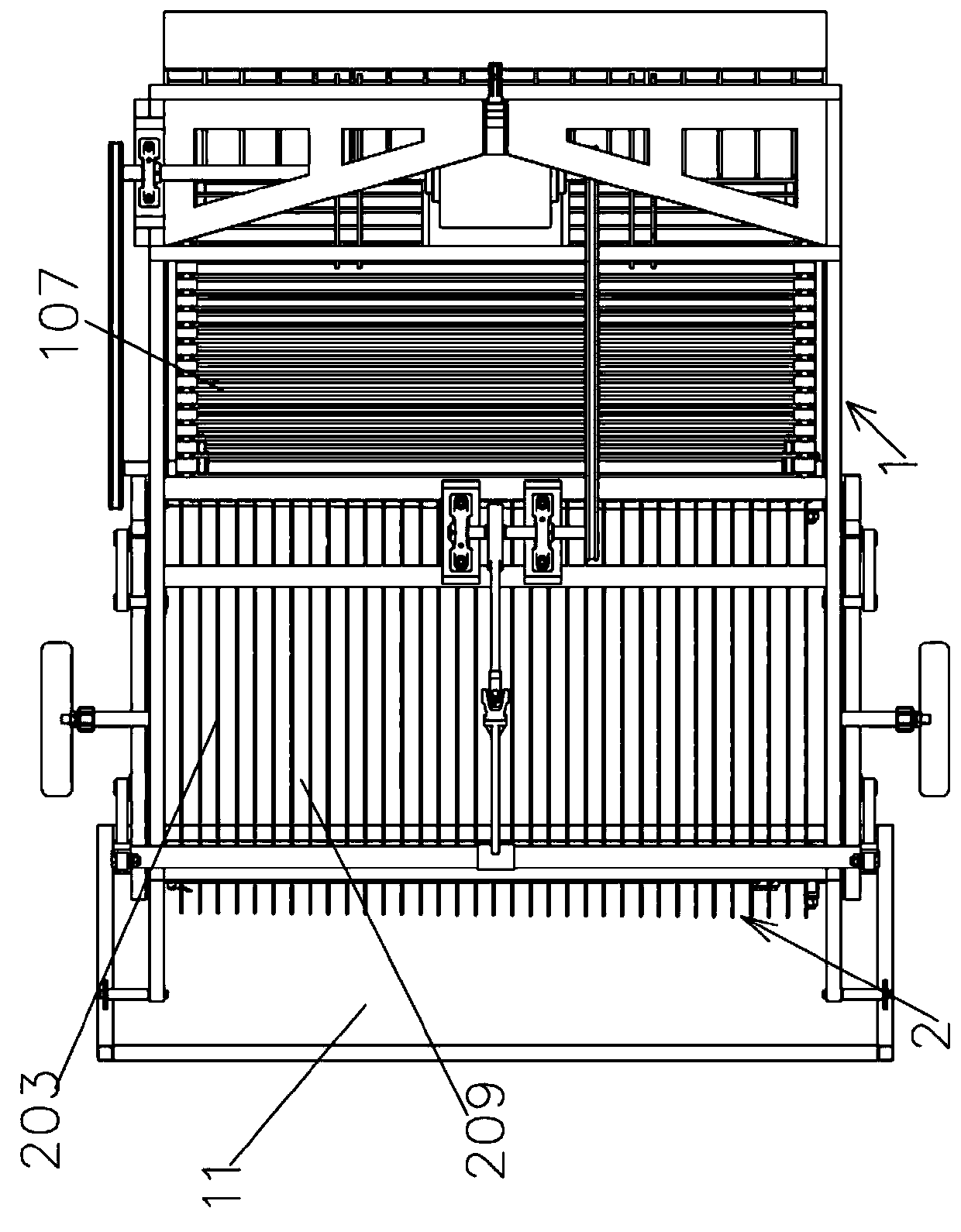

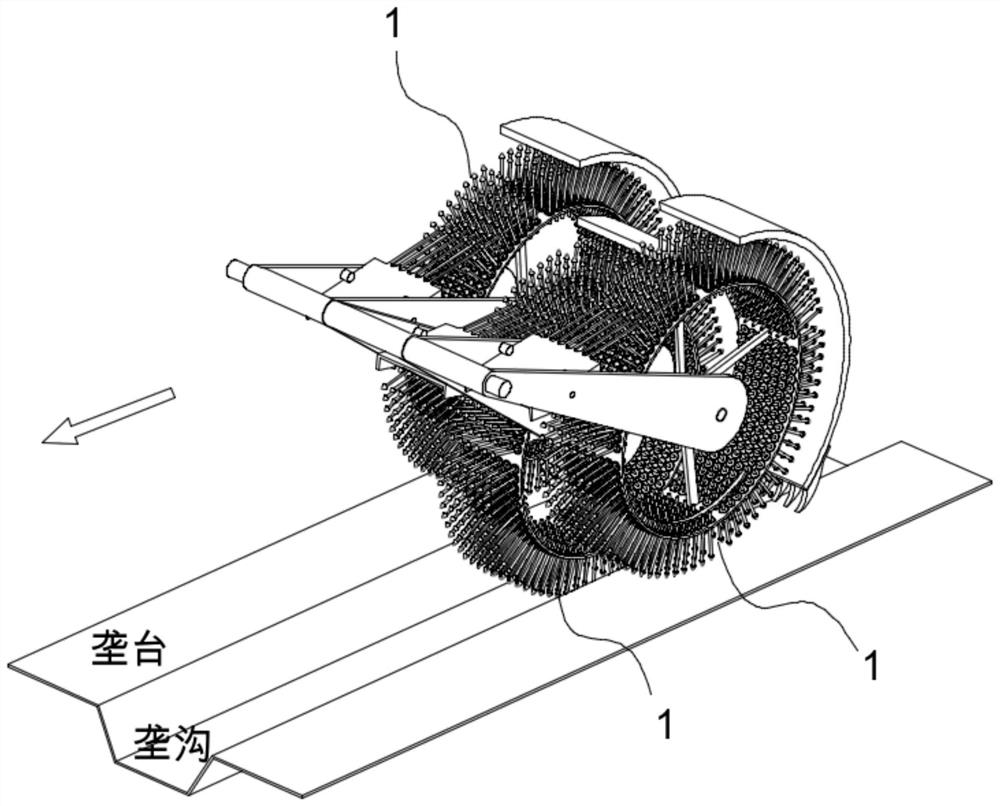

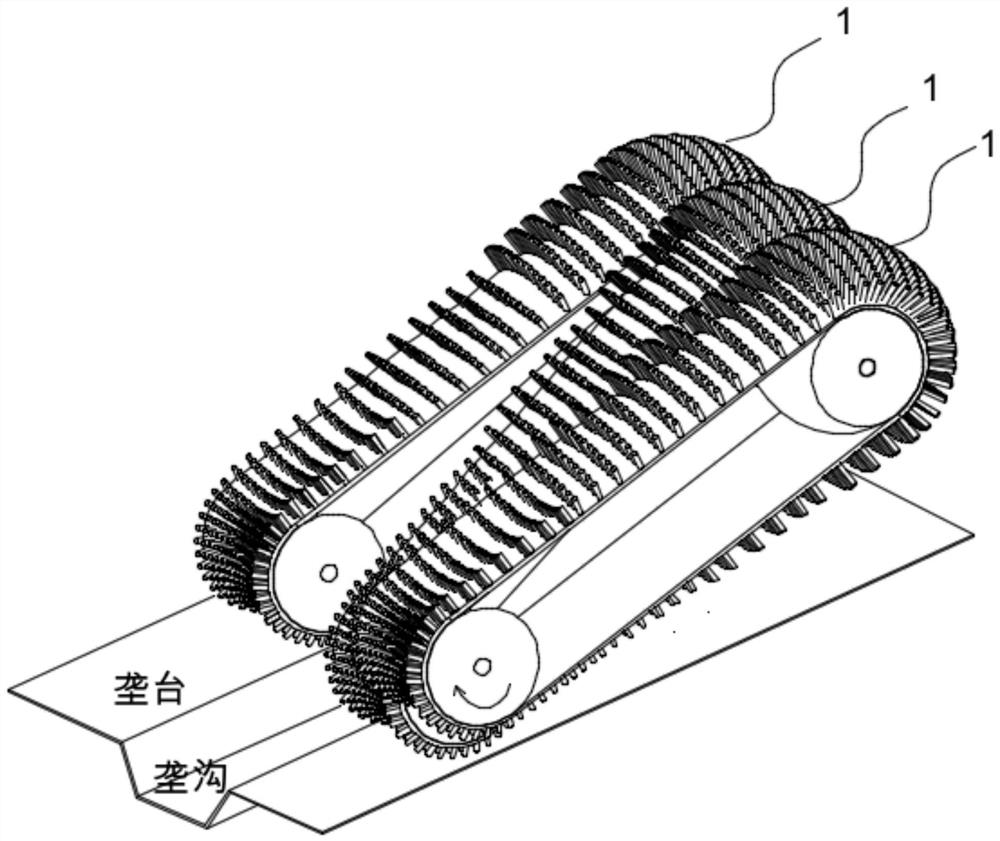

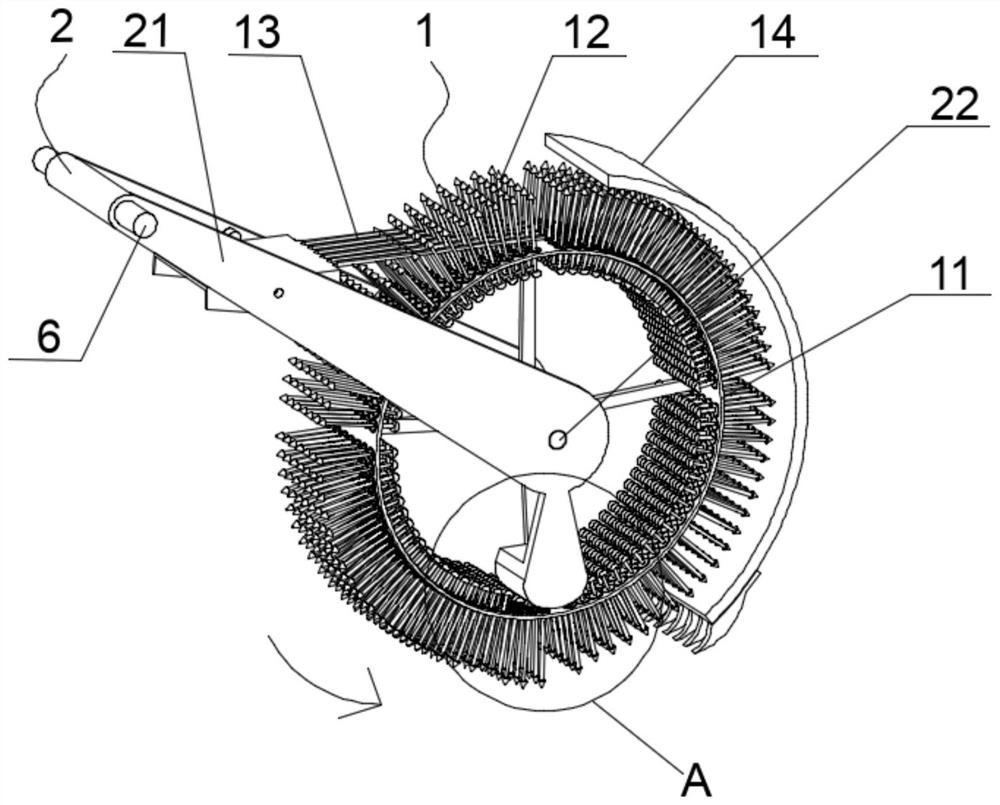

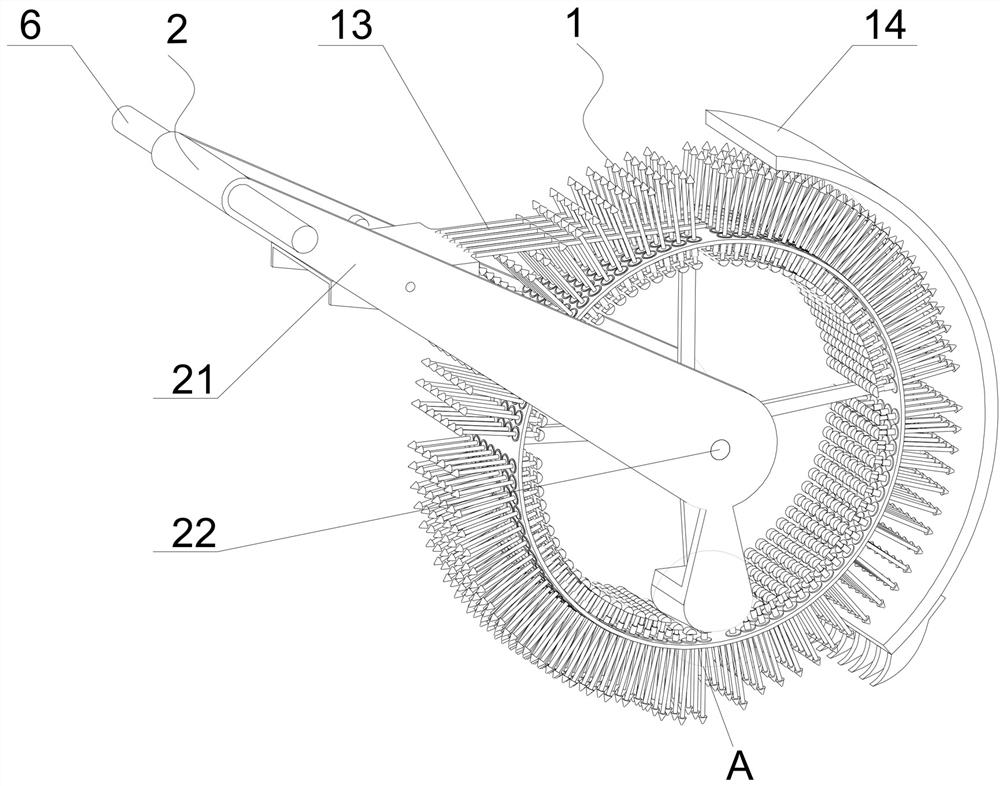

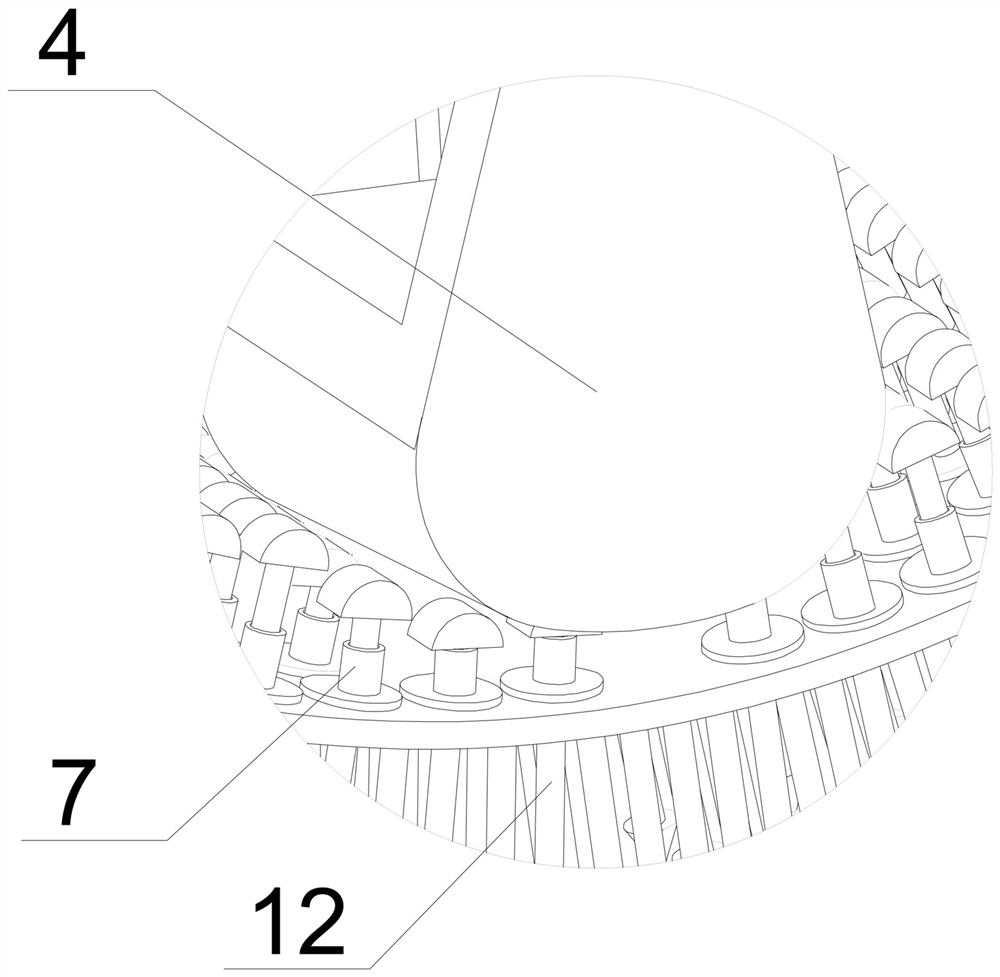

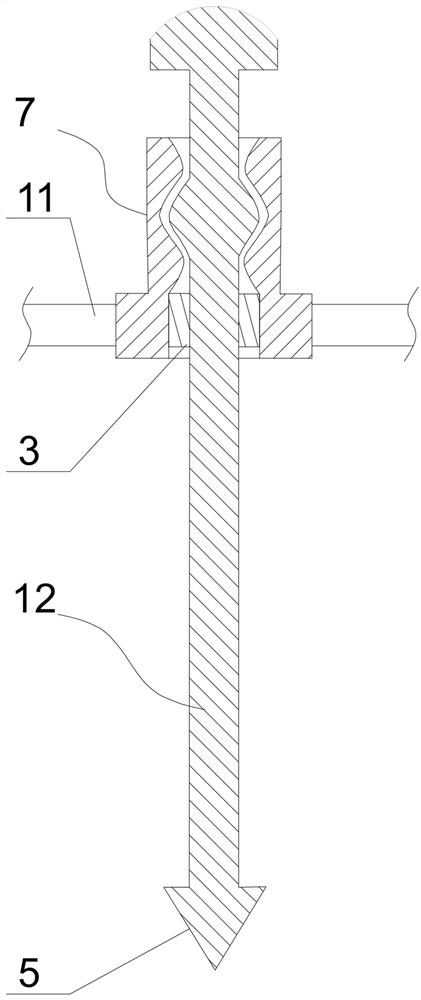

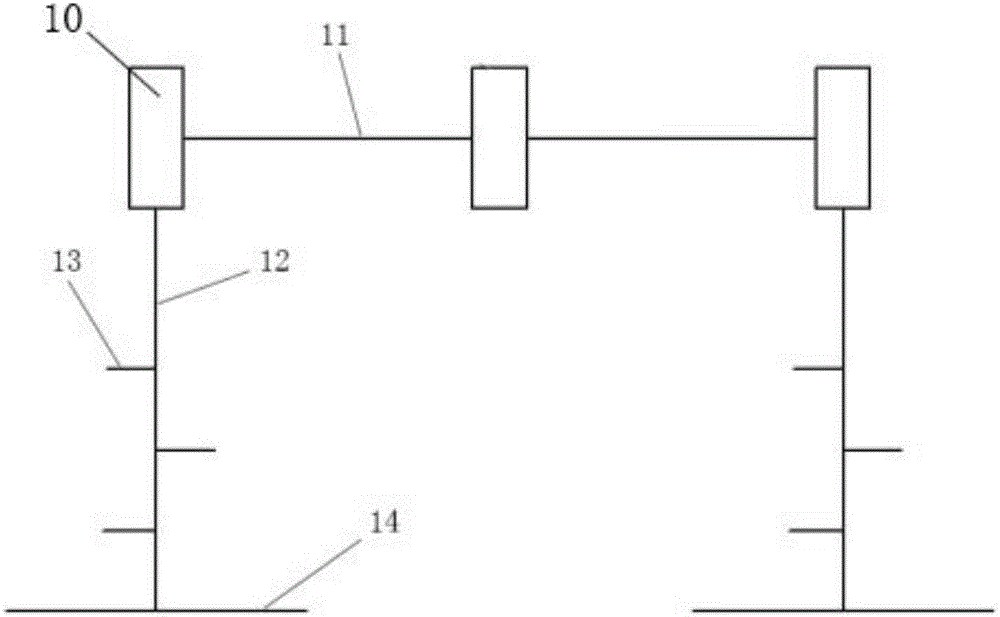

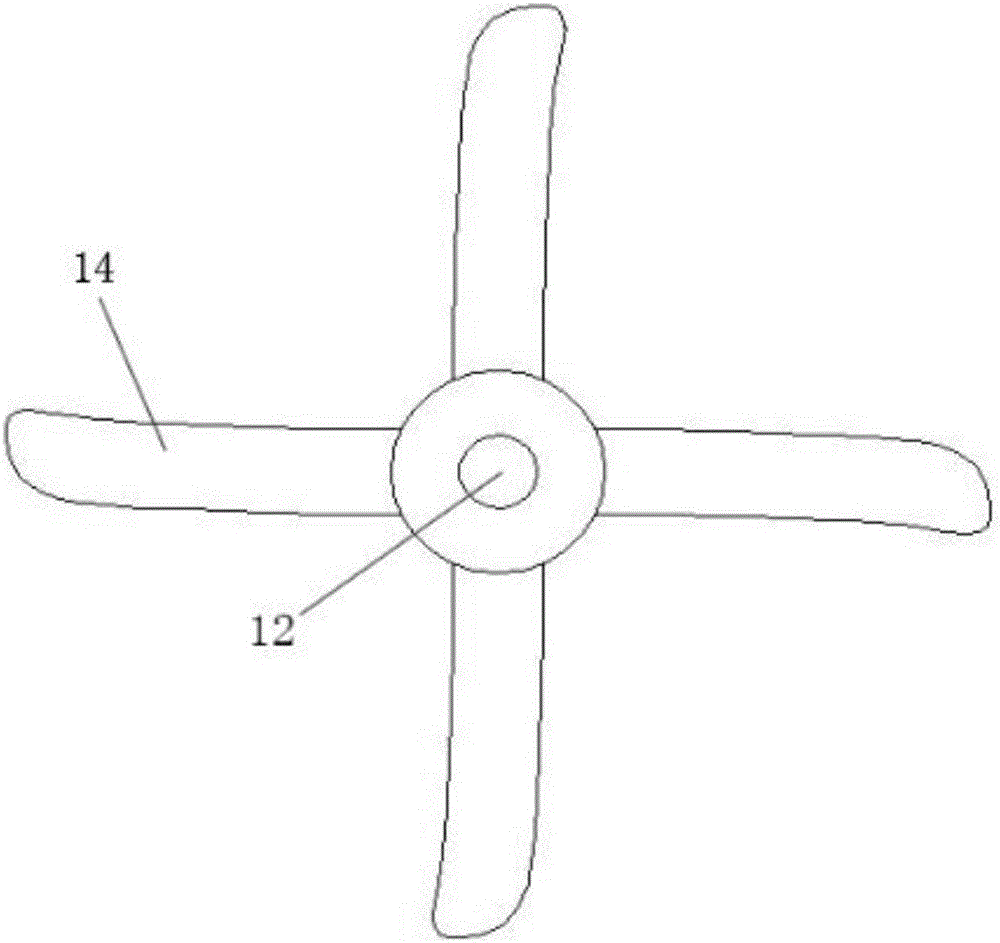

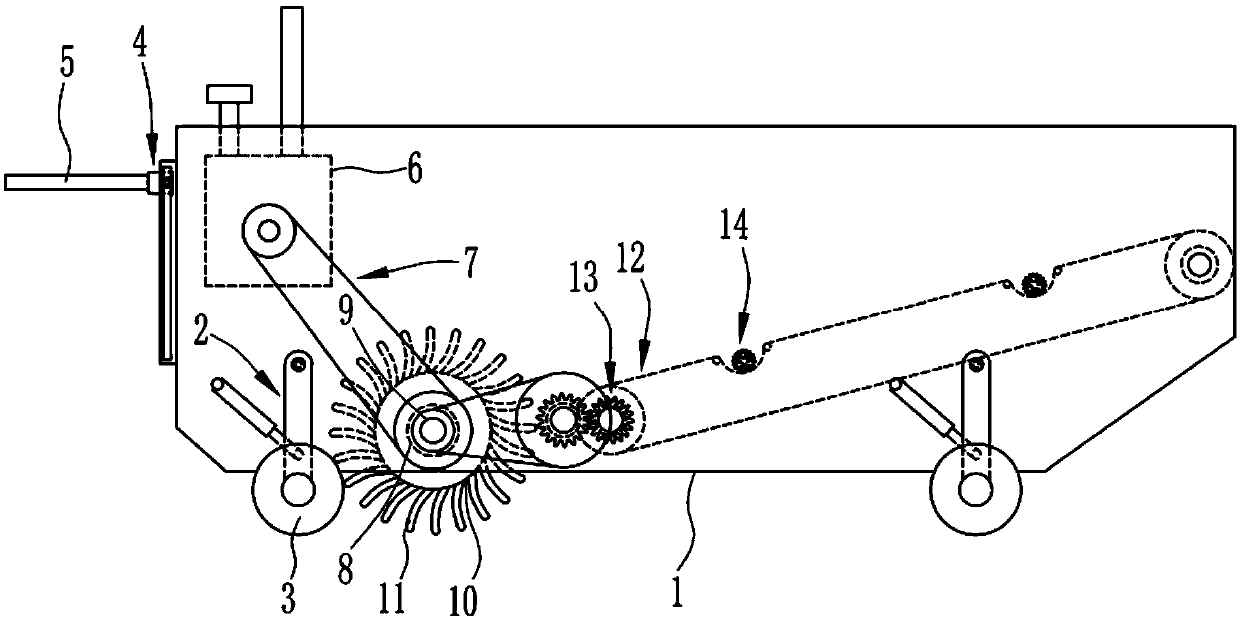

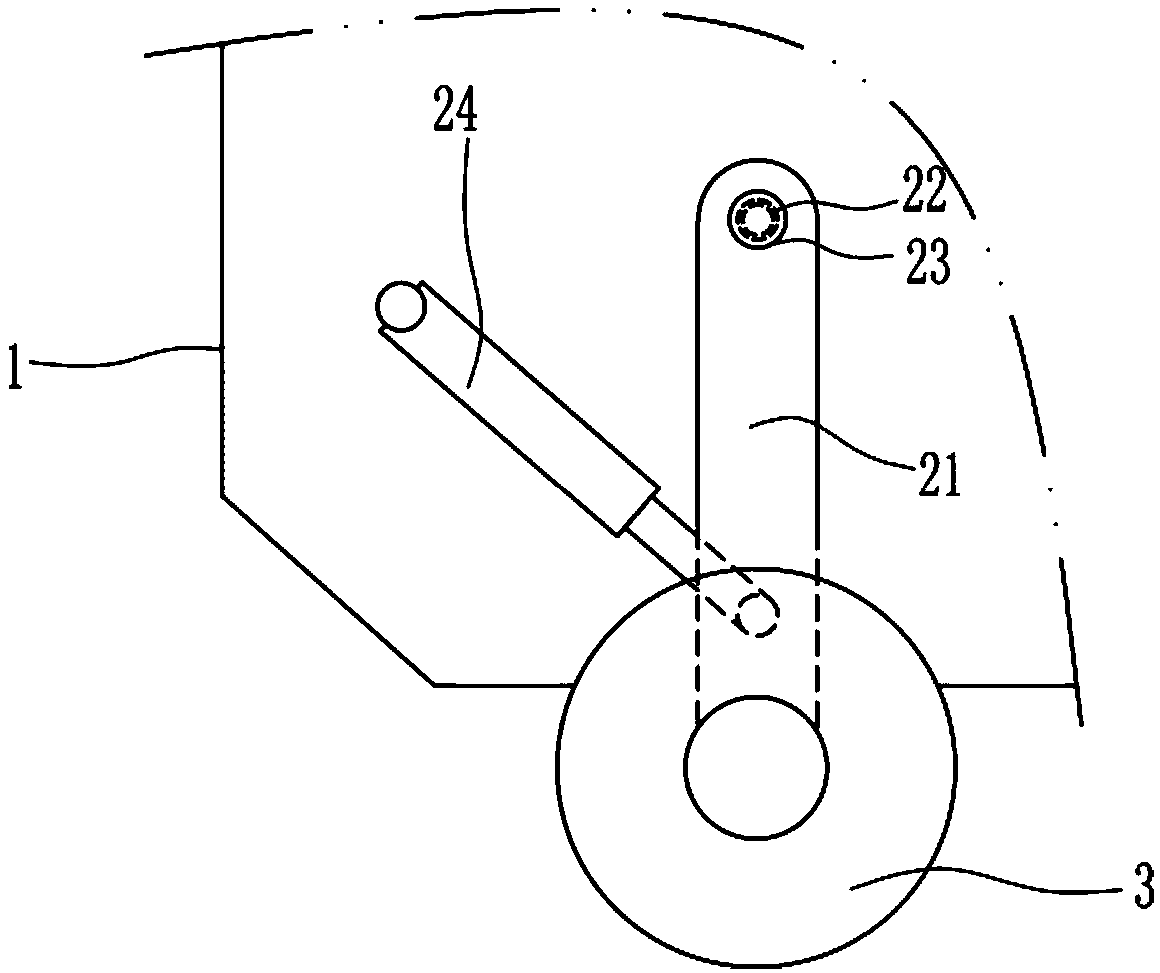

Pickup device and collecting device using same

PendingCN113632645AReduce operating costsReduce soil contentLoadersAgricultural engineeringMechanical engineering

The invention belongs to the technical field of agricultural machinery, particularly relates to a pickup device and a collecting device using the same, and aims to overcome the defect that when an existing straw pickup device is used for picking up straw in a non-flat area, pickup needles are prone to deflection, and therefore picking missing is caused. The pickup device adopts an annular movement mechanism, the annular movement mechanism comprises a pickup wheel and pickup needles distributed on the periphery of the pickup wheel in a penetrating mode, and an active pressurizing mechanism enabling the pickup needles to actively stretch out towards the ground and a straightening device arranged between the pickup needles and the pickup wheel and used for straightening the pickup needles are further arranged on the annular movement mechanism. The object to be picked up is attached to the pickup wheel by using the pickup needles and is taken away from the ground. The collecting device using the pickup device comprises a pickup device body and comb teeth, the comb teeth are arranged at the discharging end of the pickup device body, and the pickup device body is arranged on the front portion or the side portion or the rear portion of the collecting device. According to the pickup device, the situation that the pickup needles are blocked in the pickup process and deflect or deviate is effectively avoided.

Owner:哈尔滨科罗得农业装备开发有限公司

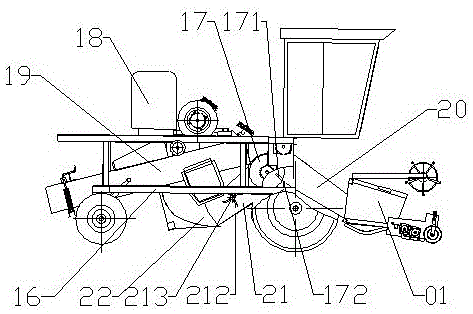

Swing type pickup mechanism for wrapping machine

The invention discloses a swing type pickup mechanism for a wrapping machine. The swing type pickup mechanism comprises a center suspension and a pickup mechanism, wherein a center shaft is fixedly arranged on the center suspension, is movably inserted in a center through hole in the pickup mechanism, and is sleeved with a torsion spring; a convex ring is fixedly arranged on the center shaft, andis movably arranged in a fixed clamp nozzle of the pickup mechanism; the pickup mechanism comprises a winder fixed rack; air bag damping seats are fixedly arranged above and under an auxiliary liftingblock; an auxiliary wheel is fixedly arranged at the end, far from the auxiliary wheel lifting block, of an auxiliary wheel elevator. The pickup mechanism can rotate around the center suspension of the pickup mechanism at a certain angle, so that the pickup mechanism and the ground are kept flush; support is provided to the pickup mechanism through the auxiliary wheel, the service life of the pickup mechanism is prolonged, and the soil content of silage is reduced.

Owner:安徽思嘉瑞机械设备有限公司

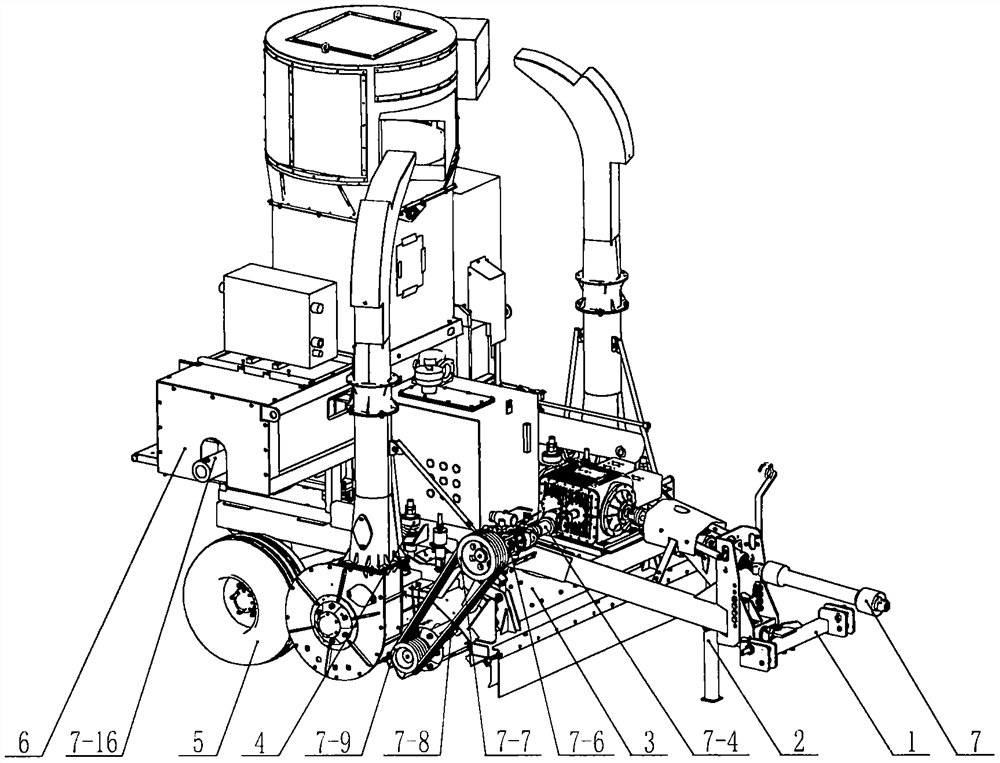

A self-propelled non-aligned cotton stalk combined harvesting and bundling machine

ActiveCN104081927BAchieving wrong harvestImprove harvesting efficiencyReaper-bindersEngineeringInternal combustion engine

The invention relates to the field of agricultural implements, in particular to a self-propelled no-row cotton stalk combine harvesting and baling machine. The self-propelled no-row cotton stalk combine harvesting and baling machine comprises a self-propelled chassis, a no-row cotton stalk harvesting platform, a chain plate conveying device, a cutting device, a slide carriage conveying device and a baling device, wherein the no-row cotton stalk harvesting platform, the chain plate conveying device, the cutting device, the slide carriage conveying device and the baling device are successively arranged on the self-propelled chassis from front to back, and all the devices are in transmission connection with an internal combustion engine. The self-propelled no-row cotton stalk combine harvesting and baling machine can harvest cotton stalks in a no-row mode, harvesting efficiency of the cotton stalks is increased, soil contents in the cotton stalks after harvest are reduced, operation procedures of harvest of the cotton stalks are simplified, and workload is reduced.

Owner:滨州市农业机械化科学研究所

Corn harvester equipped with corn straw cutting, smashing, recovering, concentrated placing and strip laying device

InactiveCN105145004ASolve the pollution problemQuality assuranceCrop conditionersMowersAgricultural engineeringWork function

The invention discloses a corn harvester equipped with a corn straw cutting, smashing, recovering, concentrated placing and strip laying device, and belongs to agricultural machinery. A hob type straw cutting cutter shaft assembly, a straw bidirectional conveying auger shaft assembly and a straw collecting baffle are sequentially arranged below the rear side of a horizontal stem pulling and ear picking roller harvesting table assembly from front to back in parallel. Straw throwing rake teeth are arranged in the middle of the straw bidirectional conveying auger shaft assembly and located at the discharge port of the middle of the straw collecting baffle. A straw smashing device with a smashed straw throwing cylinder assembly is fixedly arranged on the corn harvester. The front end and the rear end of a straw conveying assembly are connected with the discharge port of the straw collecting baffle and the feed port of the straw smashing device. A straw strip laying and unloading plate is hinged to or inserted in the lower portion of a shell of the straw conveying assembly. By means of the device, smashing, recovering or strip laying can be conducted on corn straw in the field, and the device is novel and reasonable in structure, diversified in work function, good in work quality and high in efficiency.

Owner:HARBIN LONGMU MACHINERY EQUIP CO LTD

Efficient peanut combine harvester

InactiveCN109548455ASave energyReduce soil contentDigger harvestersDifferential phaseAgricultural engineering

The invention belongs to the field of needle selectors and discloses an efficient peanut combine harvester which comprises a harvesting mechanism mainframe, a round-pipe grain lifter, a soil shaking mechanism, a pair roller differential phase fruit picking roller arranged on the harvesting mechanism mainframe, a ploughing blade arranged on the lower side of the front end of the harvesting mechanism mainframe, a seedling separator arranged on the lower side of the front end of a rack, a cleaning device arranged on the lower side of the rear end of the rack, a fruit collection box arranged abovethe cleaning device, a lifter arranged on the upper side of the cleaning device, a chassis arranged at the lower end of the rack and a traveling mechanism arranged at the lower end of the chassis ofthe rack. The efficient peanut combine harvester is simple in structure and can effectively avoid the problems of low yield and low peanut harvesting rate in the prior art.

Owner:临沭县东泰机械有限公司

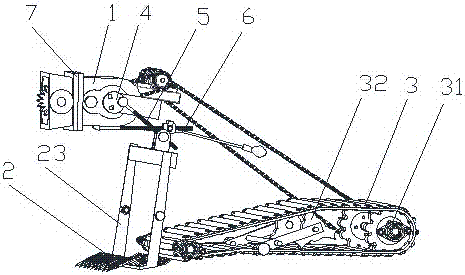

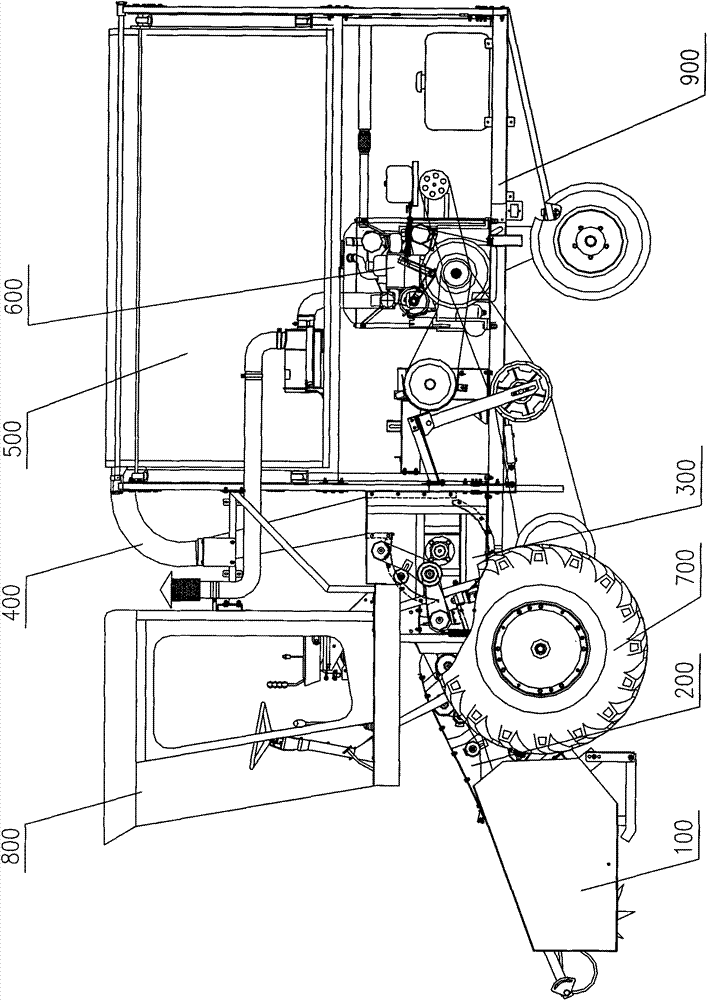

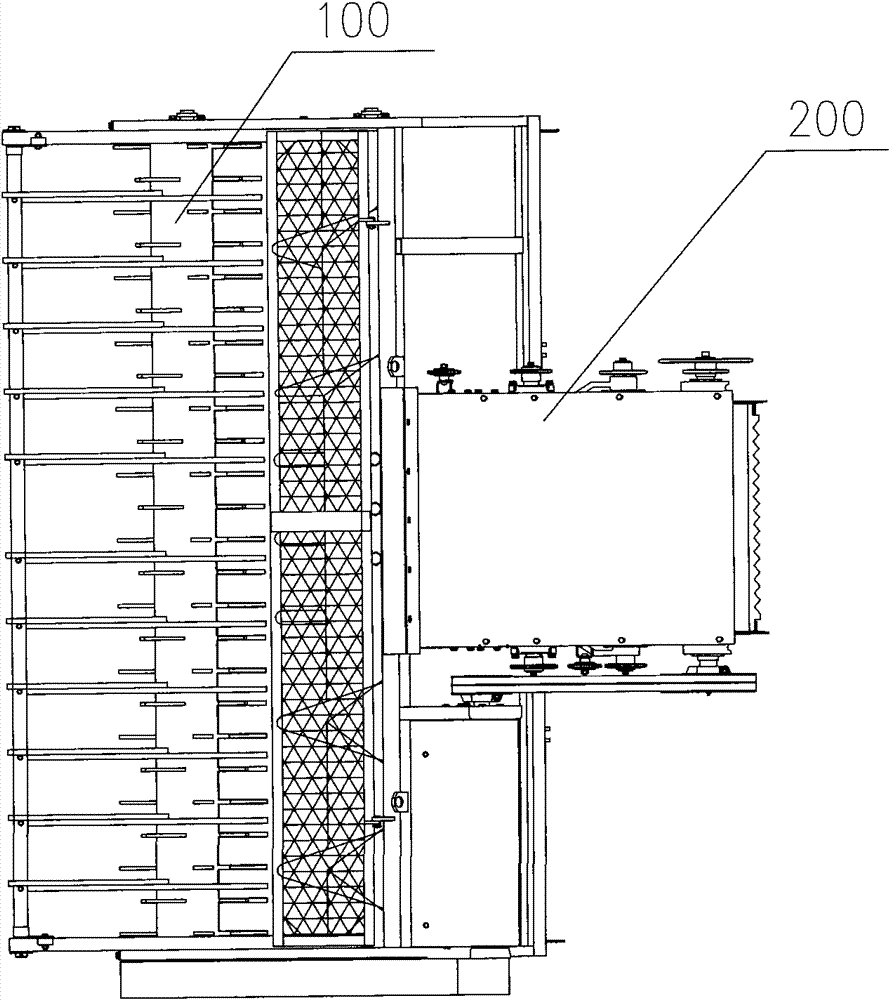

Straw harvesting method and straw harvesting machine

ActiveCN102334410BAchieve harvestMeet the needs of the harvestLoadersCrop conditionersEngineeringTillage

The invention discloses a straw harvesting method and a straw harvesting machine used for harvesting straws which are pulled down on the ground. The straw harvesting machine comprises an engine, a chopper, a thrower, a storing box, a picking and transporting platform and a gap bridge transportation device, wherein the picking and transporting platform is used for picking up the straws which are pulled down on the ground; and the gap bridge transportation device is used for transporting the picked straws; the picking and transporting platform is connected with the inlet of the gap bridge transportation device by virtue of the gap bridge transportation device; the outlet of the chopper is connected with the storing box through the thrower; and a hydraulic turnover device is installed on thestoring box; the engine is respectively in power connection with the picking and transporting platform, the gap bridge transportation device, the chopper, the thrower and the hydraulic turnover device. Through the straw harvesting method and the straw harvesting machine, the straws which are pulled down on the ground are harvested, thereby meeting the requirement of deep tillage and sowing.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Field chaff and straw picker

The invention provides a field glume and straw pickup machine and belongs to agricultural machinery. The field glume and straw pickup machine comprises a rack assembly, a power transmission case, a cross flow fan impeller assembly, a screw conveyor shaft assembly and a centrifugal fan, wherein a flow guide plate and a mesh screen are mounted at the upper side part of the rack assembly sequentially from front to back and located above the cross flow fan impeller assembly and the screw conveyor shaft assembly respectively, and a cutter is mounted on a screw conveyor shaft and between the screw conveyor shaft assembly and the centrifugal fan. The field glume and straw pickup machine can be used for picking up crop glumes and crop straw, the collected glumes and straw contain little soil, are highly clean and can be directly processed into feed or biomass fuel for use, and the field glume and straw pickup machine has the characteristics of reasonable, novel and simple structure, good operation quality and high applicability.

Owner:HEIHE FANGYUAN AGRI MACHINERY TECH DEV

Eleocharis tuberosa excavator

The invention discloses an eleocharis tuberosa excavator. The eleocharis tuberosa excavator comprises a machine frame, a vibrating screen, a clod breaking roller and a spiral digging roller; the eleocharis tuberosa excavator is characterized by further comprising a deep soil digging device; the deep soil digging device comprises a rotating shaft and a cutting slice; the upper end of the rotating shaft is assembled on the machine frame, and extends vertically and downwardly; the cutting slice is combined with the lower end of the rotating shaft in a certain angle; and the deep soil digging device is arranged between the clod breaking roller and the spiral digging roller. The eleocharis tuberosa excavator disclosed by the invention is compact in structure and high in harvesting efficiency; and, use of the labour force is greatly reduced.

Owner:广西贺州市海达机械设备有限责任公司

Tractive straw tedding and soil removing machine

The invention discloses a straw tedding and soil removing machine and in particular relates to a tractive straw tedding and soil removing machine. The technical problem to be solved by the invention is to provide a tractive straw tedding and soil removing machine capable of reducing straw soil content and straw water content and uniformly collecting straw water. In order to solve the technical problem, the invention provides such a tractive straw tedding and soil removing machine comprising a rack, height regulating systems, land wheels, a connecting mechanism, a traction frame, an engine, a driving system, first bearing blocks, a first rotating shaft, a roller, elastic feeding teeth, a conveying system, a reversing system and jittering systems; the land wheel is connected with the rack bythe height regulating system; and the traction frame is fixedly connected to one side of the rack by the connecting mechanism. By using the tractive straw tedding and soil removing machine, the effects of reducing straw soil content and straw water content and uniformly collecting straw water are achieved.

Owner:张桂春

Self-propelled corn harvesting machine

InactiveCN105580556AReduce soil contentMeet the requirements of the demand sideHarvestersEconomic benefitsEngineering

The invention discloses a self-propelled corn harvesting machine. A cornstalk collector, a soil remover and a bundling machine are arranged behind a header of the harvesting machine in sequence, and the cornstalk collector and the bundling machine are in power connection with a power device of the harvesting machine; the soil remover is provided with a screen drum which is fixedly connected with a machine frame through a support, a feed inlet in one end of the screen drum is communicated with a discharge outlet of the cornstalk collector through a feeding pipeline, and a discharge outlet in the other end of the screen drum corresponds to a feed inlet of the bundling machine; a shaft lever is installed in the screen drum, screw blades are fixedly connected to the shaft lever, the two ends of the shaft lever are connected to the screen drum in a rotary mode, and the shaft lever is in power connection with the power output end of the power device through a power transmission mechanism; the power input end of the cornstalk collector and the power input end of the bundling machine are in power connection with the power device through power transmission mechanisms respectively. By the adoption of the self-propelled corn harvesting machine, corn ears and cornstalks can be collected at the same time, soil in cornstalk fragments can be screened out through the soil remover, and economic benefits of farmers can be increased after baled cornstalks are sold.

Owner:SHULAN CITY TONGYONG MACHINERY

Material crushing and square bundle forming machine

PendingCN114246071AReduce soil contentPick up effect is goodMowersBalingAgricultural scienceAgricultural engineering

The invention belongs to the technical field of agriculture and animal husbandry machinery, and particularly relates to a smashing square bundle forming machine capable of harvesting crop straw. The machine mainly comprises a traction frame body, a supporting frame, a crushing and dust removing header, a floating profiling mechanism, a walking mechanism, a forming mechanism and a transmission system. The material crushing and square bundle forming machine is driven and dragged by a tractor, can perform continuous operations of cutting, picking, feeding, crushing, conveying, dust removing, compression forming, net winding and bundle discharging on standing or lodging long straws, and adapts to the current crop straw harvesting development direction in China. The harvester has the characteristics of good picking effect, high crushing degree, low soil content of materials, ideal forming effect, stable transmission system, high reliability and the like.

Owner:HUHHOT BRANCH OF CHINESE ACAD OF AGRI MECHANIZATION SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com