Self-propelled no-row cotton stalk combine harvesting and baling machine

A self-propelled, baler technology, applied in the field of agricultural machinery and tools, can solve the problems of large power consumption, work in the soil, and difficulty in improving the harvesting efficiency of cotton stalks, and achieve the effects of reducing workload, reducing soil content, and reducing soil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

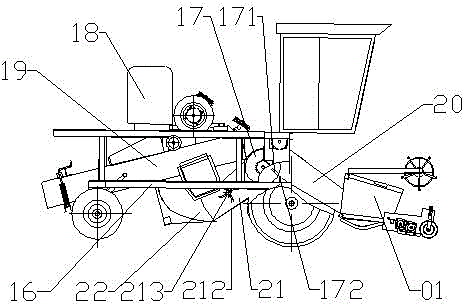

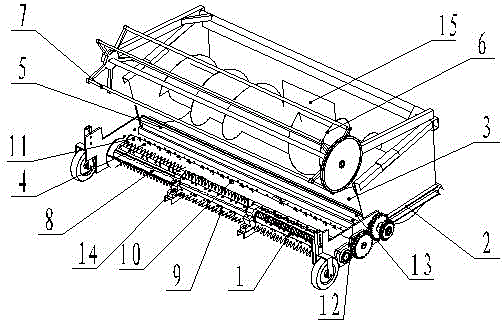

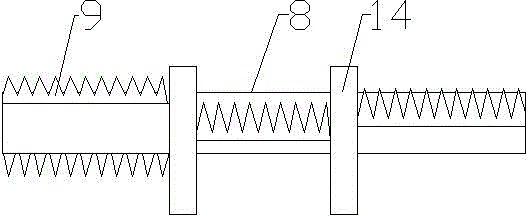

[0034] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 11 As shown, this kind of self-propelled non-opposing cotton stalk combined harvesting and bundling machine includes a self-propelled chassis 16, a cutting device 17 fixedly installed on the self-propelled chassis 16, a bundling device 19 and an internal combustion engine 18, and the cutting device 17 includes a rotating The knife group 171 and the fixed knife 172 also include a slide plate conveying device 21 fixed on the self-propelled chassis 16 and a chain plate conveying device 20 hinged on the front end of the self-propelled chassis 16. The front end of the chain plate 201 conveying device 20 is fixedly connected. Cotton stalk pulling platform 01, the cutting device 17 is located behind the chain plate conveying device 20, behind the cutting device 17 are the sliding plate conveying device 21 and the bundling device 19, the self-propelled chassis 16, the non-align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com