Feeding device of row-alignment-free corn harvester header

A corn harvester and feeding device technology, applied in the field of agricultural harvesting, can solve the problems of being easily pushed down, increasing the contact between the reel chain and reel teeth and corn stalks, and the reliability of easy blockage, so as to achieve good harvest , reduce power consumption, and prevent congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

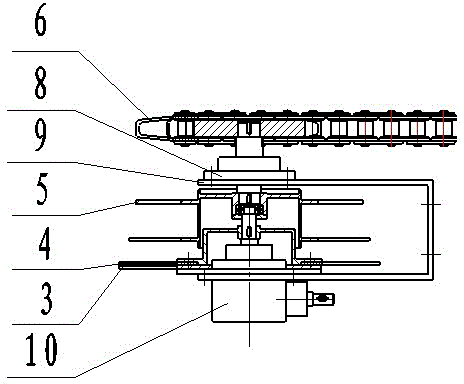

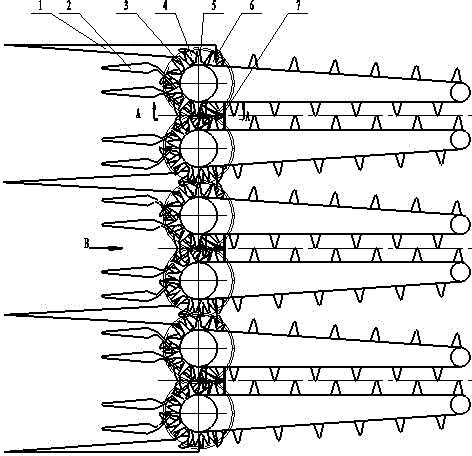

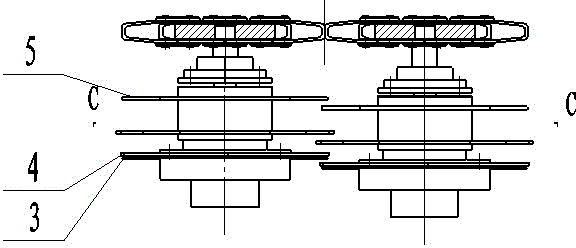

[0017] 1. Large grain divider 2. Small grain divider 3. Fixed knife 4. Moving knife 5. Reeling drum 6. Reeling chain 7. Grass guard 8. Bearing seat 9. Frame 10. Gear box.

[0018] combine figure 1 In the shown embodiment, the corn harvester walks opposite to each other in the field, the grain dividers 1 and 2 assist the separation of the straw, the movable knife 4 cuts the straw, and the cut straw passes through the entrance under the action of the reel chain 6 and the reel 5 . It enters the clamping and conveying state, and completes the process of straw clamping and conveying and ear picking of corn ears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com