Small-line-spacing corn harvester header

A technology of corn harvester and small row spacing, which is applied in the direction of harvesting platforms, harvesters, agricultural machinery and implements, etc., which can solve the problems such as difficult to meet corn, and achieve the effect of large applicable row spacing, flexible and convenient use, and small model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

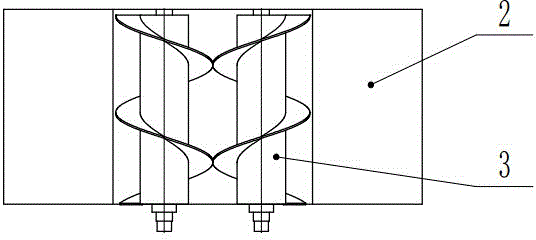

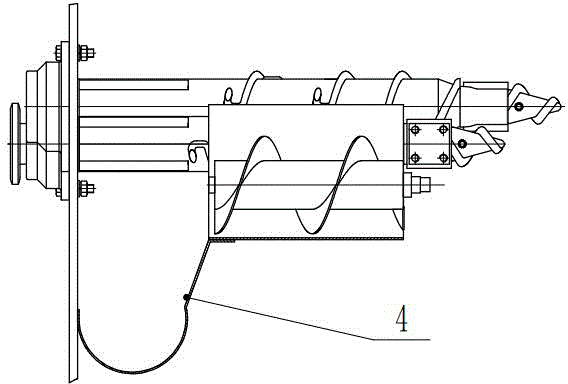

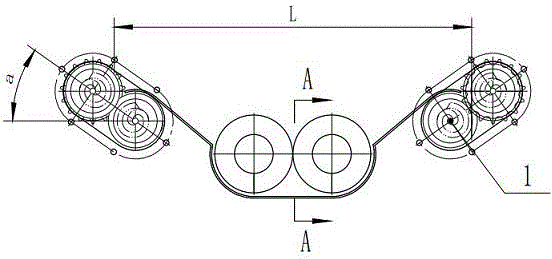

[0012] This embodiment is used to illustrate the present invention, but not to limit the present invention in any way. As attached figure 1 , 2 , 3 shows: the installation panel is installed on the rack, the picking roller group (1) is installed on the panel, and is welded together with the frame at the same time. Each group of picking rollers has length and height, and short picking rollers In the low position, the long picking roller is in the high position, and the power of the picking roller is input from the rear end; the longitudinal corn slide (2) is installed on the frame, and its upper part covers the upper surface of the short picking rollers on both sides, and the lower part is In the conveying trough of the longitudinal conveying auger (3), the power of the longitudinal conveying auger (3) can be input by the front end; the ears of the longitudinal conveying auger fall into the ear collecting trough (4). During its work, after the corn is picked by the ear picking r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com