Process for regenerating plastic woven bag by utilizing waste plastics

A technology of waste plastic and recycled plastic, applied in the field of plastic woven bag production, can solve the problem of inconvenient cleaning of soil, and achieve the effect of reducing soil content, improving production quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A process for utilizing waste plastics to regenerate plastic woven bags, comprising the following steps:

[0029] (1) Classify the collected waste plastics and perform pretreatment. Place the waste plastics in clean water under 600-800W ultrasonic power for cleaning. After cleaning, put them into a centrifuge and process them at a speed of 2000r / min for 10-15 minutes. ;

[0030] (2) After the pretreatment is completed, crush the waste plastics into 1-1.5cm plastic fragments, and then put the crushed fragments into the cleaning solution for 20-40min. The cleaning solution consists of water, 10mol / Acetic acid with a concentration of L and hydrochloric acid with a concentration of 12mol / L are composed according to the volume ratio of 100:10:10; stir during the soaking process, rinse with water for 5 minutes after completion, and then put it into a centrifuge, the temperature is controlled at 60-80°C, Process at a speed of 2000r / min for 15-20 minutes to obtain crushed raw...

Embodiment 2

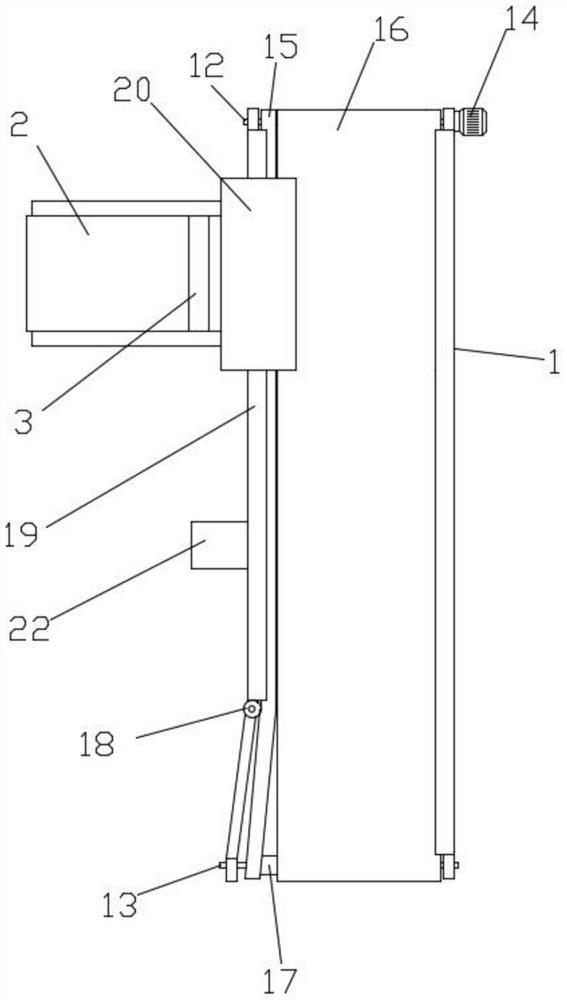

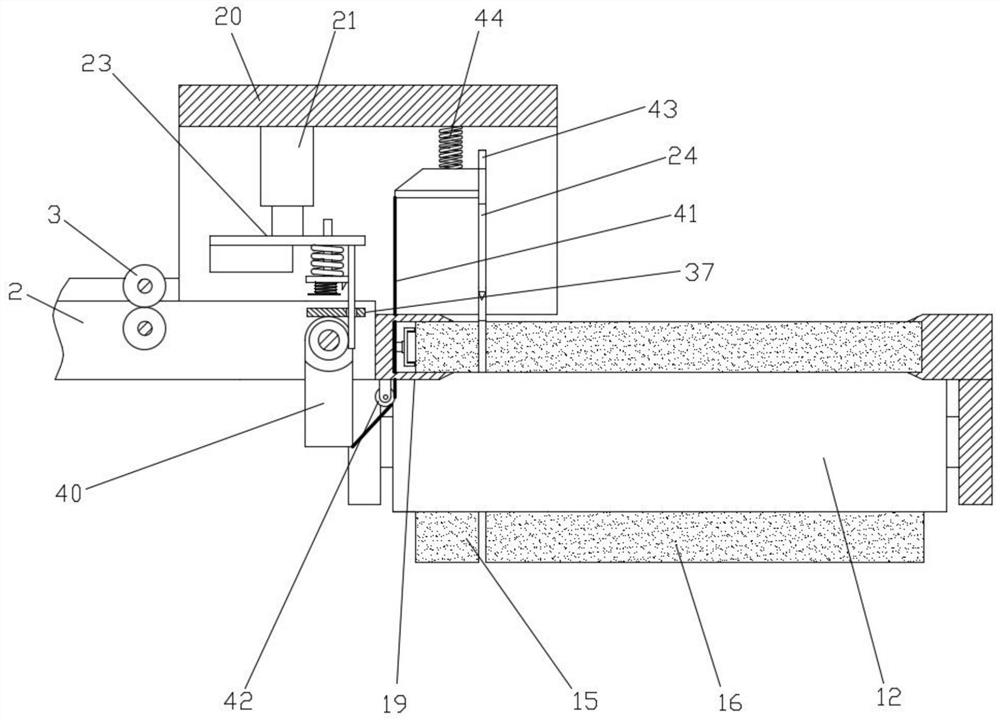

[0036] On the basis of Example 1, such as Figure 1-5As shown; after the woven material is cut, the cut edge needs to be hemmed. In the prior art, the cut material is directly input to the conveyor belt, and the conveyor belt is used to transport the cut material to the hemming machine. In this process , the cutting material lacks positioning during the conveying process of the stitched side, and it is easy to cause the stitching side to deviate during conveying, so it is necessary to perform side-to-side operations, which affects production efficiency. Therefore, an integrated cutting and seaming machine is set up, which includes : device support 1, the upper part of the device support 1 is provided with a material roll feeding table 2, and one side of the material roll feeding table 2 is equipped with a feed pair roller 3;

[0037] A first drive shaft 12 and a second drive shaft 13 are installed on the device support 1, the first drive shaft 12 is driven by a stepper motor 1...

Embodiment 3

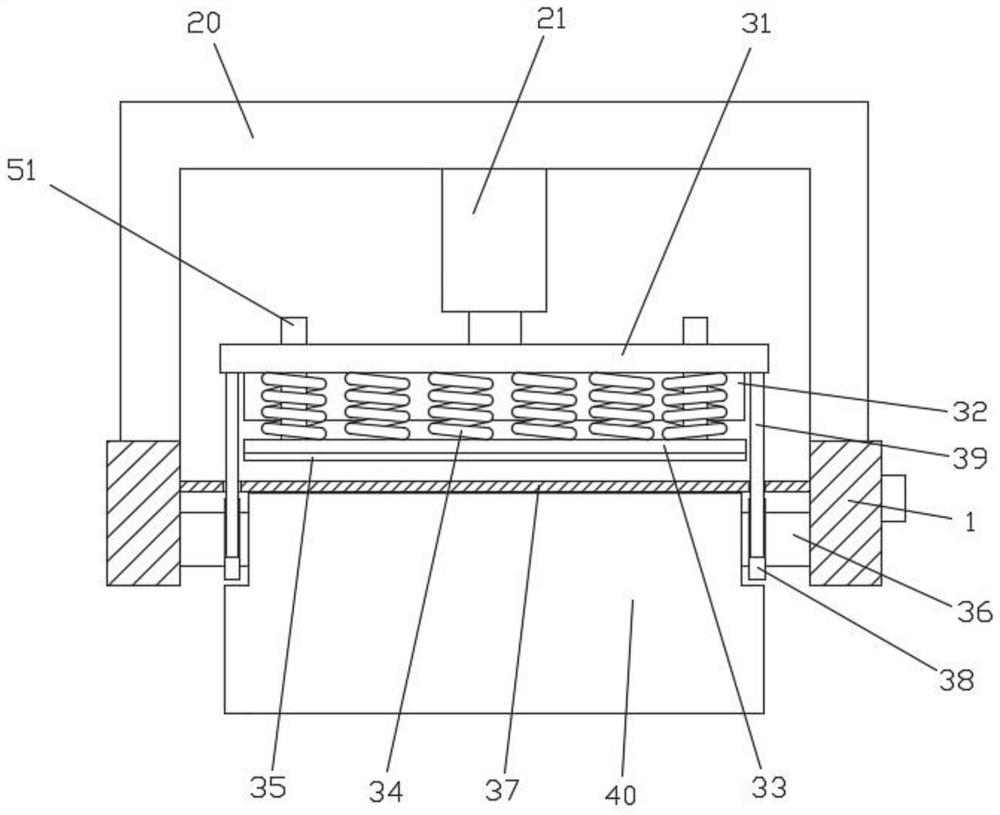

[0042] On the basis of Example 2, such as Figure 4 As shown; the upper part of the cutter plate 33 is fixed with a column 51, the column 51 is slidably inserted into the cutter frame 31, the column 51 is perpendicular to the cutter plate 33, the limit spring 52 is installed on the bottom of the cutter plate 33, and the bottom of the limit spring 52 is fixed Bead 53 is arranged, and bead 53 is positioned at backing plate 37 tops.

[0043] When the cutter plate 33 moved down, the bead 53 contacted the braided material in advance, and when the electric push rod 21 stretched out, it squeezed the limit spring 52, so that the bead 53 extruded the backing plate 37, thereby realizing pre-fixing of the braided material, preventing After the braid is cut, the ends of the braid fall off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com