Straw cleaning and harvesting device with three cutter shafts

A technology of harvesting device and cutter shaft, which is applied in the direction of headers, harvesters, cutters, etc., can solve the problems of high soil content of straw, long broken sections, and straw can not meet the requirements of direct feeding, etc. Good silk effect and strong palatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

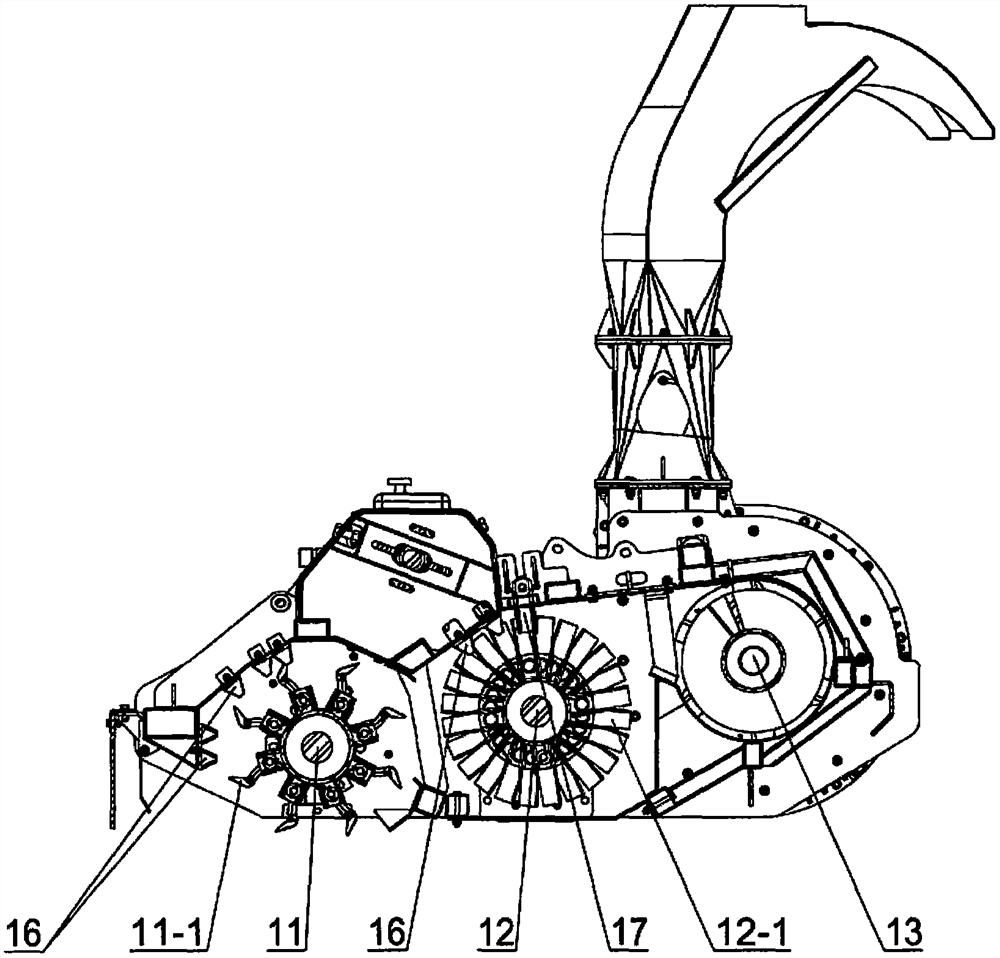

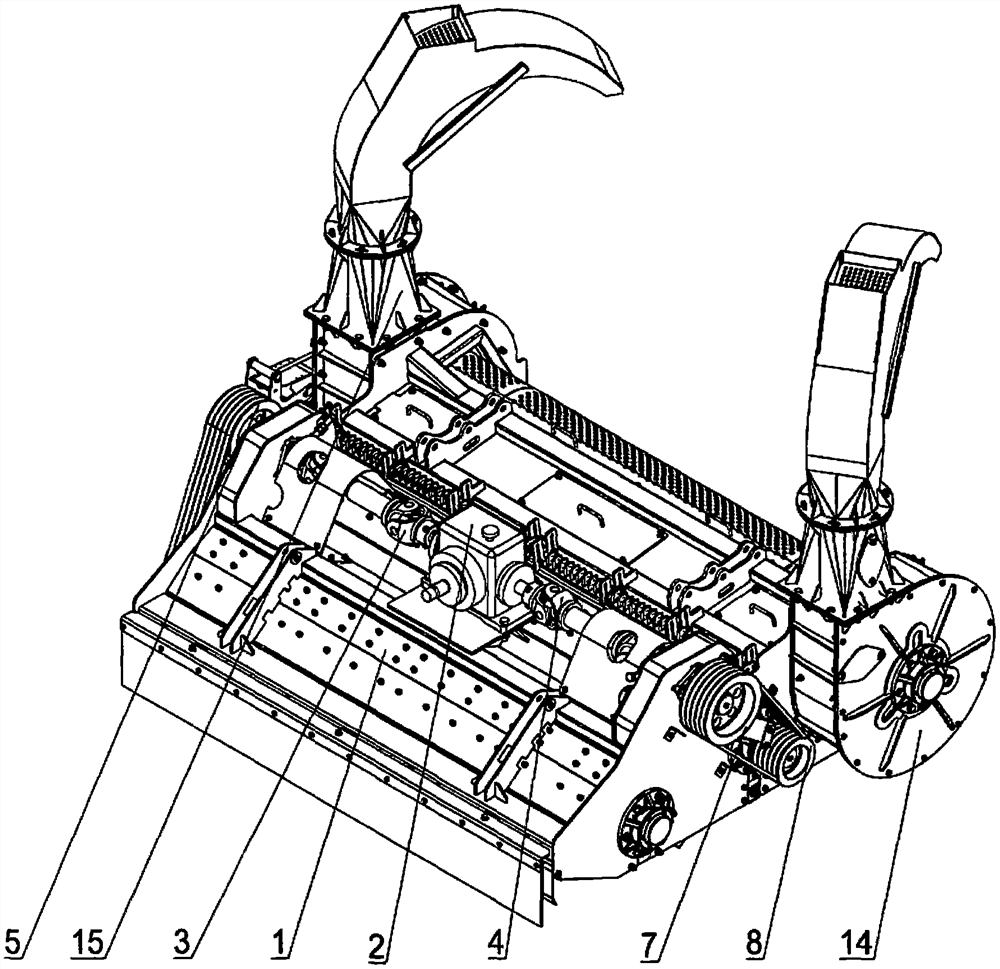

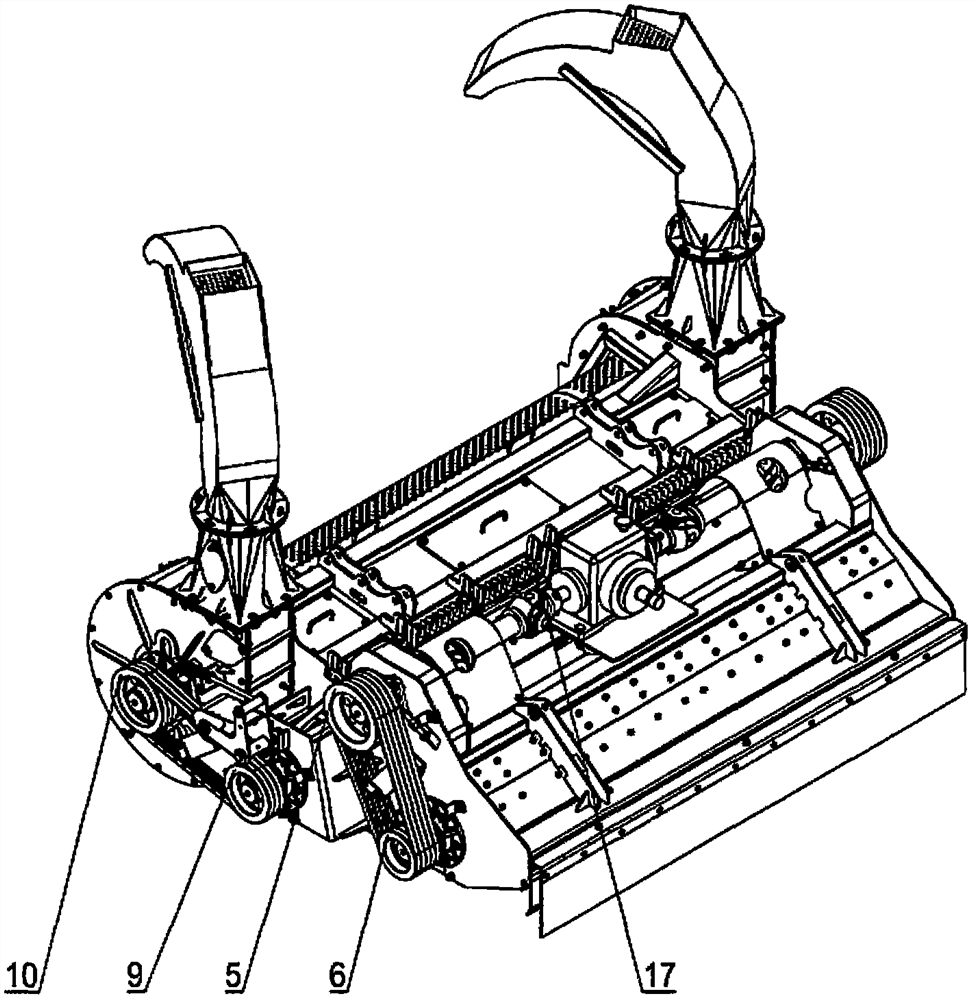

[0017] The present invention is described further according to accompanying drawing:

[0018] see Figure 1-3 , the present invention is a three-cutter shaft straw cleaning and harvesting device, which mainly consists of a header body (1), a secondary gear box (2), a right power output shaft (3), a left power output shaft (4), a front knife Shaft driving pulley (5), front cutter shaft driven pulley (6), primary driving pulley (7), primary driven pulley (8), secondary driving pulley (9), secondary driven pulley (10) , front cutter shaft (11), middle throwing cutter shaft (12), rear auger (13), fan casing (14), feeding cylinder (15), fixed knife welding (16), adjustable Knife (17) forms.

[0019] The secondary gearbox (2) is fastened to the middle position above the header frame body (1) by bolts, and its output shafts are respectively connected with the right power output shaft (3) and the left power output shaft (4) through splines; The power output shaft (3) is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com