Shell machining device for ammeter production

A technology for processing devices and casings, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of affecting processing efficiency, increasing costs, inconvenient to take out finished products, etc., to facilitate rapid cooling and forming, saving resources and costs, The effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

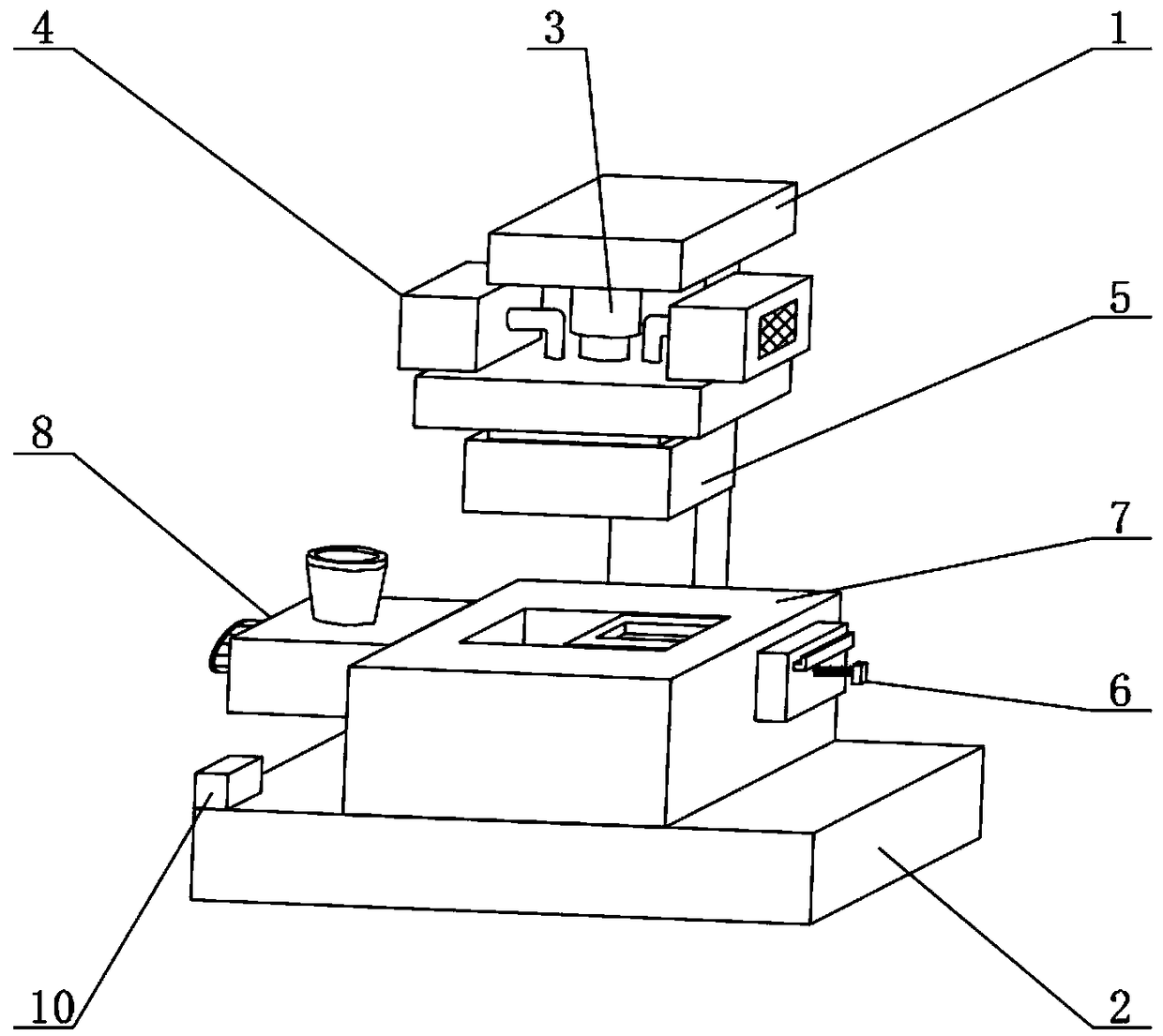

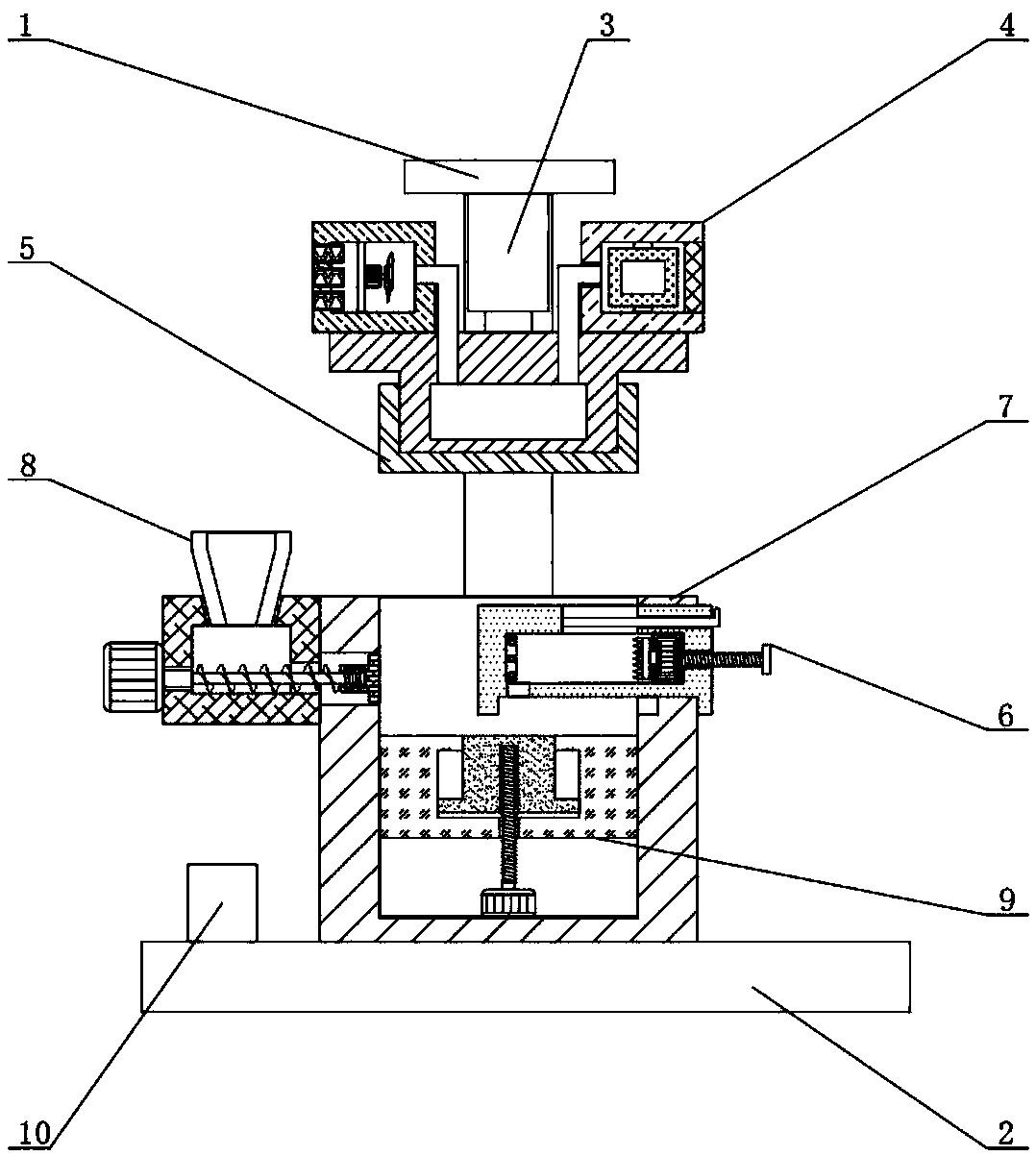

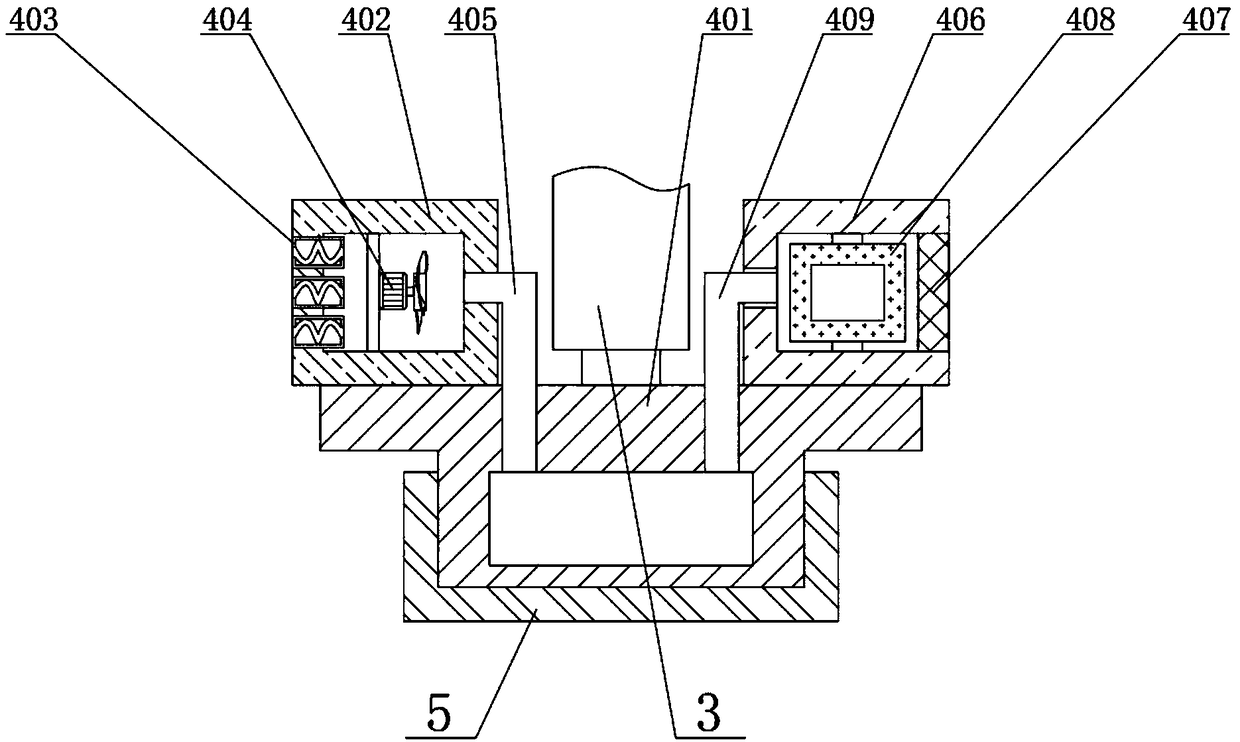

[0028] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution:

[0029]A shell processing device for electric meter production, comprising a fixed frame 1, a preheating and rapid cooling device 4, a first feeding device 8 and a material pushing device 9, the bottom surface of the fixed frame 1 is fixedly connected with a base 2, and the top and bottom of the fixed frame 1 The side is provided with an electric telescopic rod 3, and the electric telescopic rod 3 is fixedly connected with the fixed frame 1, and the bottom surface of the electric telescopic rod 3 is fixedly connected with a preheating rapid cooling device 4, and the preheating rapid cooling device 4 includes a convex mold 401, a bellows 402, Condenser pipe 403, fan 404, first air pipe 405, positioning box 406, filter screen 407, water tank 408 and second air pipe 409, the bottom end surface of electric telescopic rod 3 is fixedly connected with conv...

Embodiment 2

[0033] see figure 1 , figure 2 , image 3 , Figure 5 , Image 6 with Figure 7 , the present invention provides a technical solution:

[0034] A shell processing device for electric meter production, comprising a fixed frame 1, a preheating and rapid cooling device 4, a second feeding device 6 and a material pushing device 9, the bottom surface of the fixed frame 1 is fixedly connected with a base 2, and the top and bottom of the fixed frame 1 The side is provided with an electric telescopic rod 3, and the electric telescopic rod 3 is fixedly connected with the fixed frame 1, and the bottom surface of the electric telescopic rod 3 is fixedly connected with a preheating rapid cooling device 4, and the preheating rapid cooling device 4 includes a convex mold 401, a bellows 402, Condenser pipe 403, fan 404, first air pipe 405, positioning box 406, filter screen 407, water tank 408 and second air pipe 409, the bottom end surface of electric telescopic rod 3 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com