Material crushing and square bundle forming machine

A molding machine and molding mechanism technology, which is applied in the directions of presses, harvesters, agricultural machinery and implements, can solve the problems of unsatisfactory feeding cleanliness, high soil content of materials, and large transportation volume, and achieves ideal molding results. , The effect of low soil content of materials and stable transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

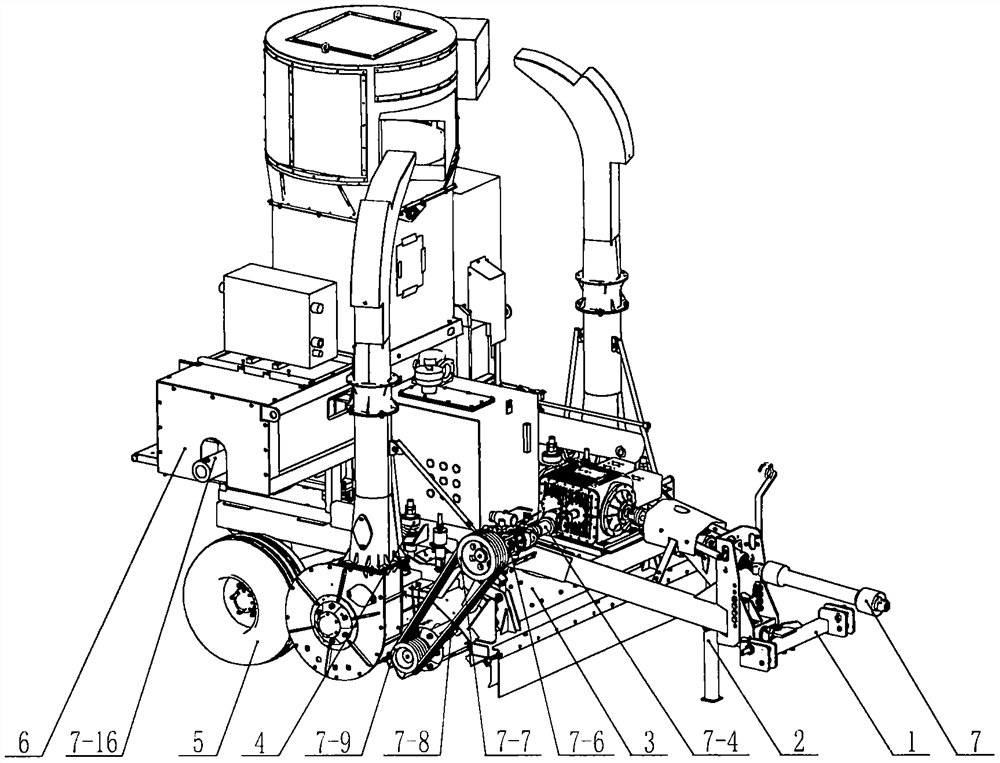

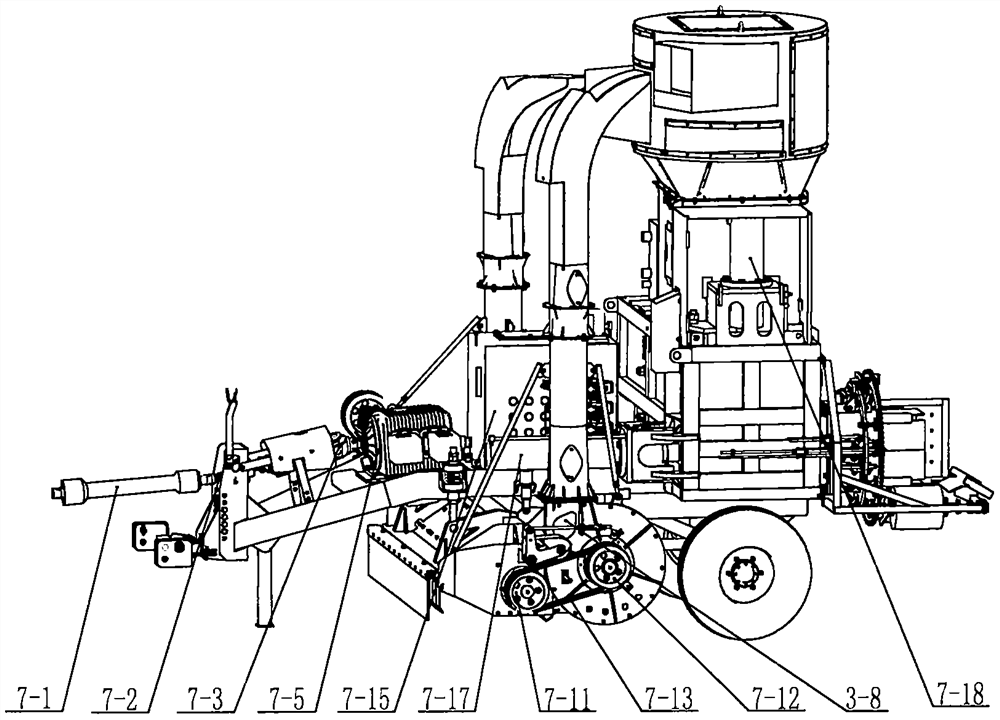

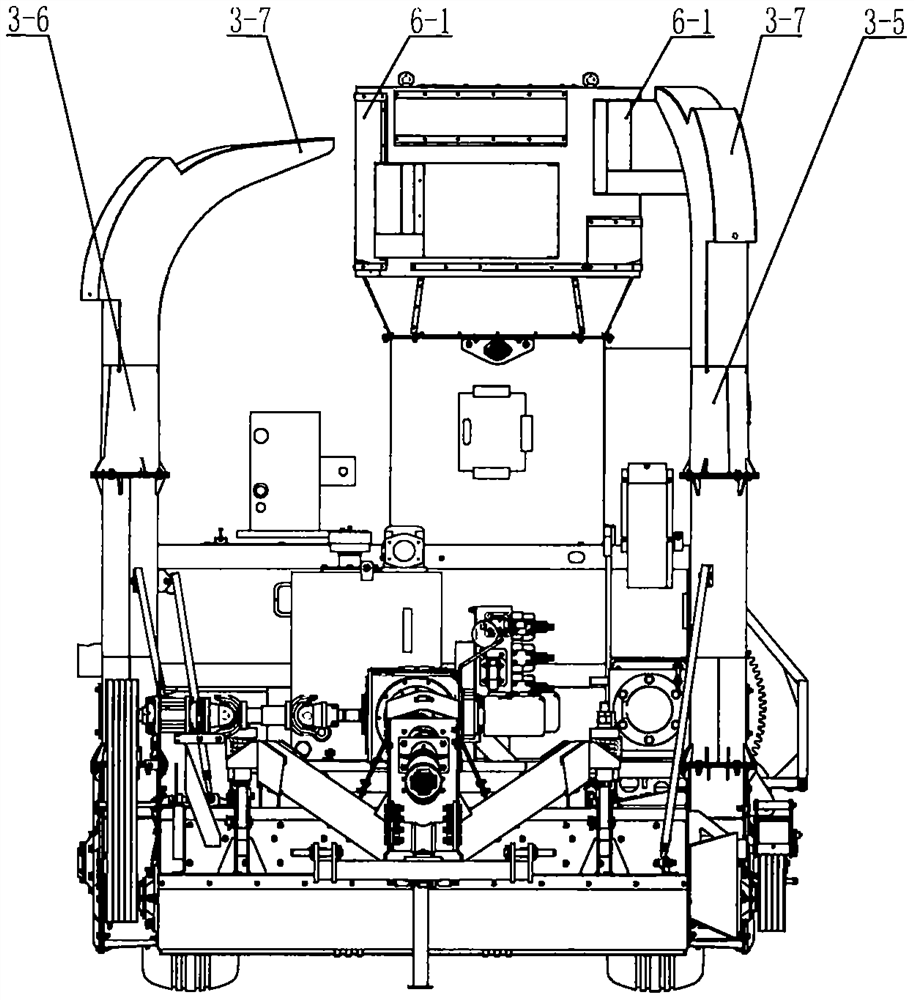

[0018] A material crushing square bale forming machine, mainly comprising a traction frame body (1), a support frame (2), a crushing and dust removal header (3), a floating profiling mechanism (4), a traveling mechanism (5), a forming mechanism (6 ) and transmission system (7). The support frame (2) is located at the front end of the traction frame body (1), and is connected with the traction frame body (1) by a pin shaft. The crushing and dust removal header (3) is hooked under the traction frame body (1) through the floating profiling mechanism (4). -6), the outlets (3-7) of the dust removal pipes (3-5) and (3-6) on both sides are longitudinally staggered and placed in the grass box inlet (6-1) of the forming mechanism (6) middle. The running gear (5) is fixed below the traction frame body (1) with a threaded connection. Forming mechanism (6) is fixed on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com