A traction-type straw tumbling and desoiling machine

A soil remover and traction technology, which is applied in the field of traction straw soil removal machine, can solve the problems of large soil content, high moisture content of straw, uneven moisture content of straw, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

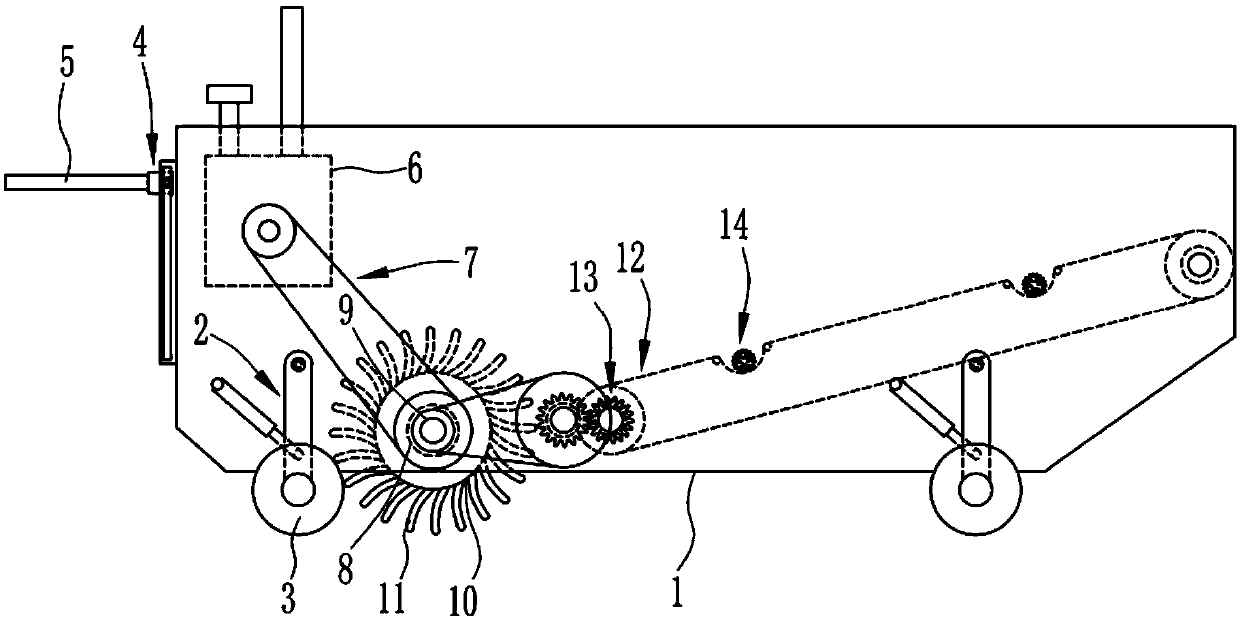

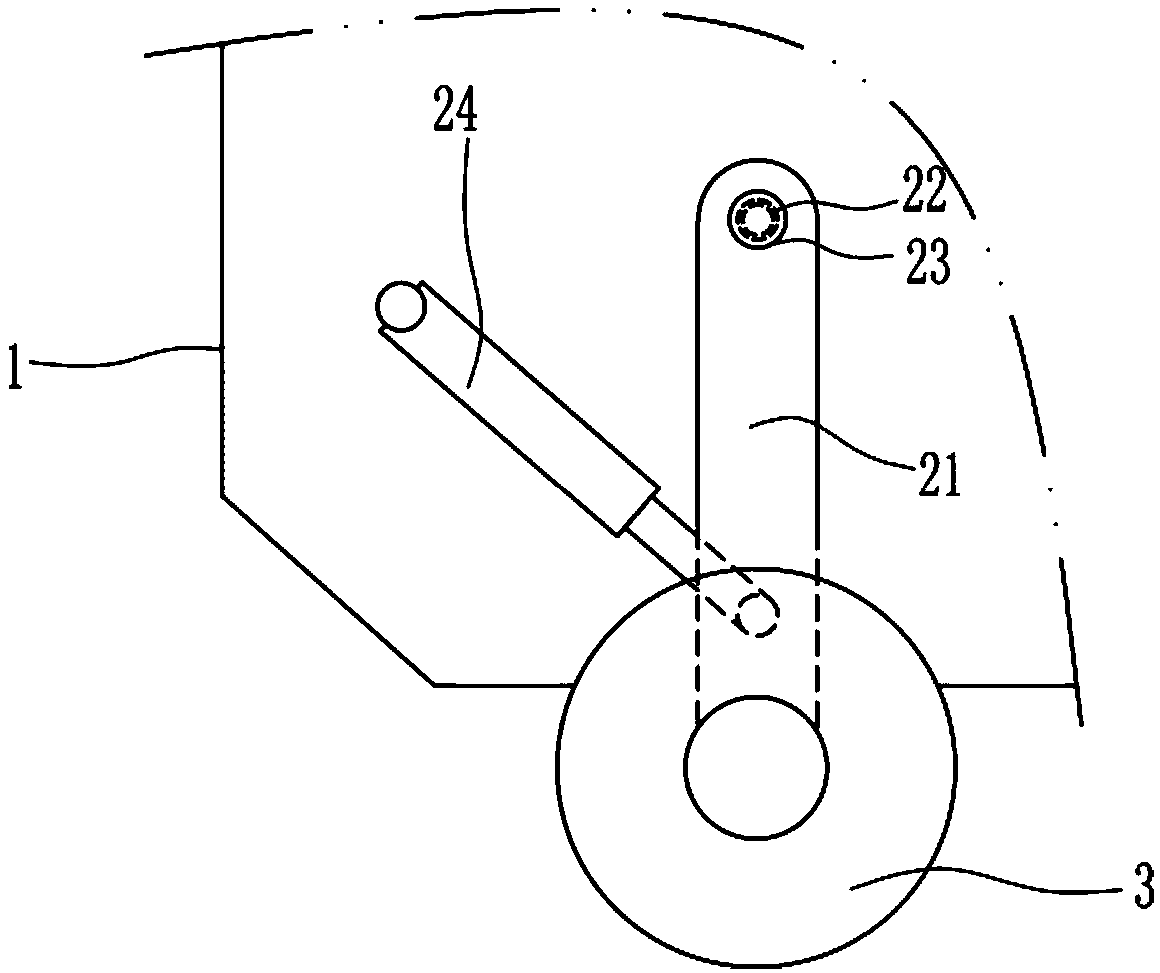

[0043] A traction-type straw tumbling and desoiling machine, such as Figure 1-11 As shown, it includes a frame 1, a height adjustment system 2, a ground wheel 3, a connecting mechanism 4, a traction frame 5, an engine 6, a transmission system 7, a first bearing seat 8, a first rotating shaft 9, a drum 10, and a feeding bomb. Teeth 11, conveying system 12, reversing system 13 and shaking system 14; the ground wheel 3 is connected to the frame 1 through the height adjustment system 2, the traction frame 5 is fixed to one side of the frame 1 through the connecting mechanism 4, and the engine 6 is installed On the side near the traction frame 5 in the frame 1, the first bearing seat 8 is embedded on the front and rear side walls of the frame 1; the first rotating shaft 9 is pivotally connected with the first bearing seat 8, and the front end of the first rotating shaft 9 is driven The system 7 is connected to the output end of the engine 6 by transmission; the drum 10 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com