Self-propelled corn harvesting machine

A corn harvester, self-propelled technology, applied in the direction of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of manpower occupation, pollution of the atmospheric environment, and impact on crop growth, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

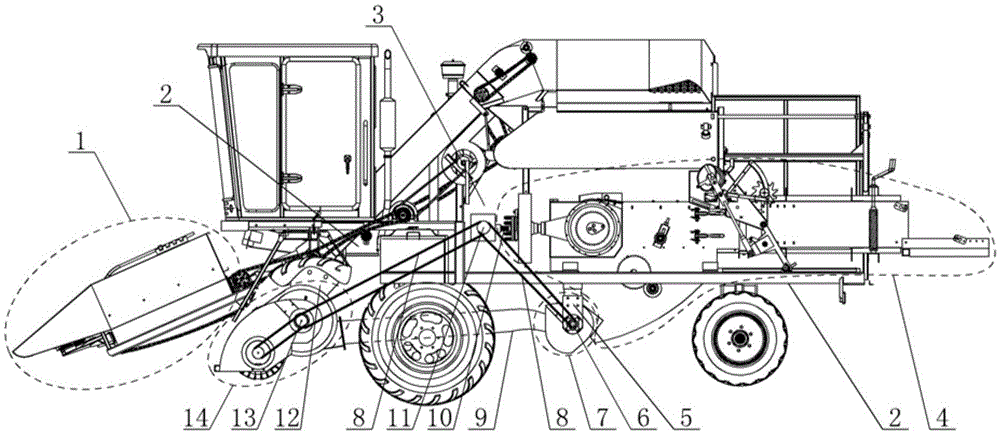

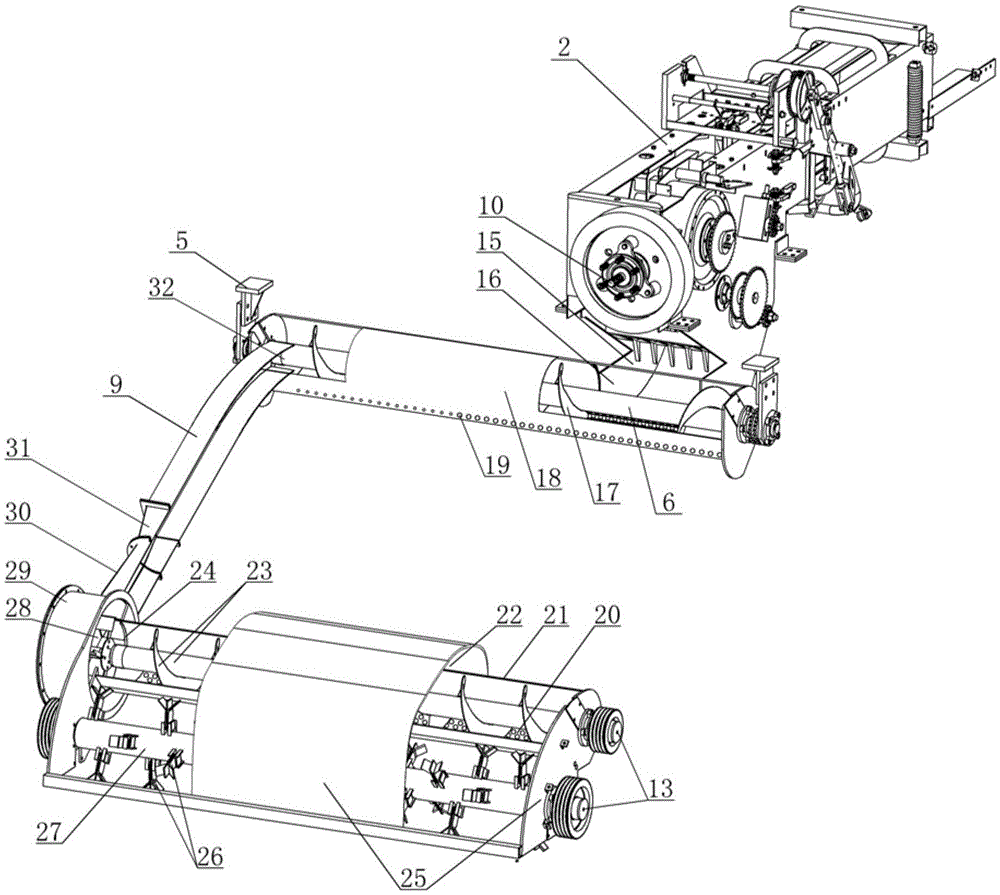

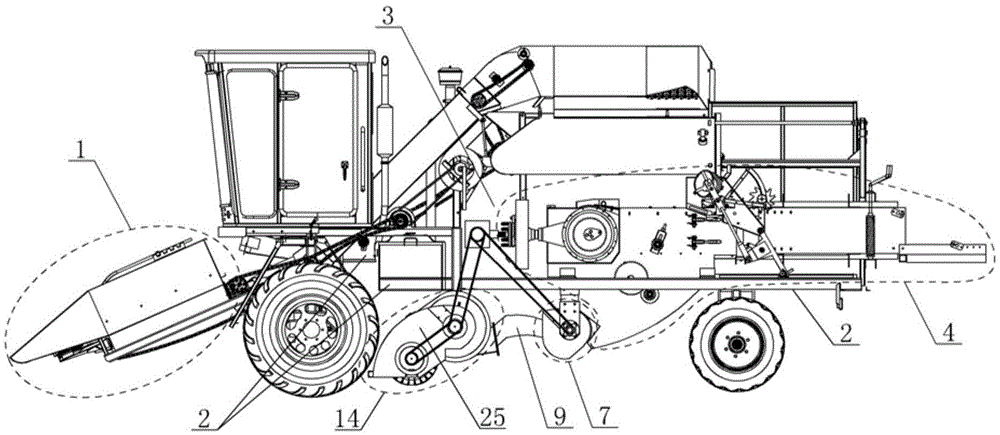

[0014] Self-propelled corn harvester, including the frame of the harvester 2, the power unit 3 installed on the frame, the harvesting platform 1 installed at the front of the frame, and the straw collector 14 and the stalker 7 behind the harvesting platform. With the baler 4, the straw collector is connected to the frame through the mounting frame 12, the body of the baler is fixedly connected to the frame, and the power input end 13 of the straw collector and the power input end 10 of the baler are respectively transmitted through power The mechanism 8 is dynamically connected to the power output end 11 of the power plant. The determinator has a screen cylinder 18, which is fixedly connected to the frame through a bracket 5, and the feed port 32 at one end of the screen cylinder is collected with straw through a feeding pipe 9 The discharge port of the machine is connected. The feeding pipe is provided with a hose section 31. The discharge port 16 at the other end of the screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com