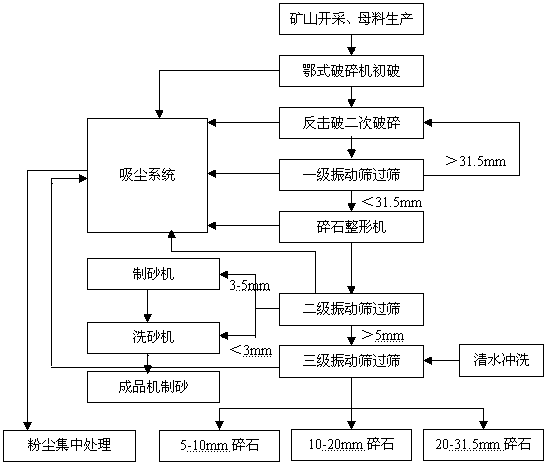

Machine-made sand processing process

A processing technology and machine-made sand technology, which is applied in grain processing and other directions, can solve problems such as large crushing index, many needle particles, and large fineness modulus, and achieve high-quality products, excellent quality, and fineness modulus. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] First, the base material excavated from the mine passes through a 10m-long vibrating screen to manually screen out the mud and low-strength master material in the rubble, and then enters the feeding port of the jaw crusher. After the block stone is decomposed into blocks not larger than 350mm, it enters the impact crusher;

[0019] Second, the impact crusher breaks the block stone into gravel, which enters the first-level vibrating screen. After screening, the crushed stone smaller than 31.5mm enters the impact crusher through the conveyor belt, and the crushed stone larger than 31.5mm passes through the conveyor belt. The crushing machine is re-crushed; after the crushed stone enters the impact crusher, the aggregate runs at high speed in the shaping machine, and the high-speed impact and friction between the aggregates make the crushed stone with weak resistance to external force broken under the action of external force , crushing, and finally form particles with reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com