Central axis type iron and stone mixing cavity in vertical shaft impact crusher

A technology of vertical shaft impact and mixing chamber, which is applied in the direction of grain processing, etc., and can solve the problems of weakened effect, great waste, and insufficient utilization of anvils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

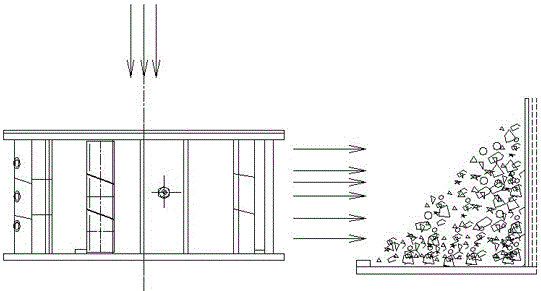

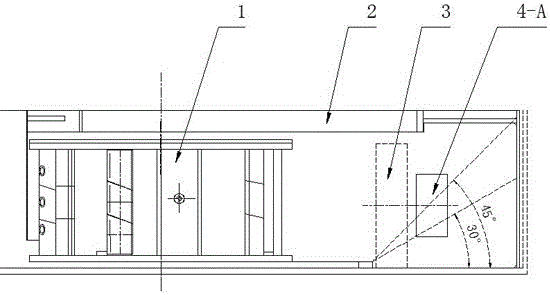

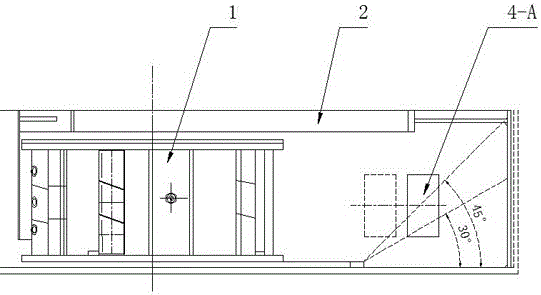

[0053] In order to improve the crushing efficiency of the vertical shaft impact crusher, improve the fineness modulus of crushable materials, reduce the content of stone powder, reduce the steel consumption per ton of finished products, and improve the adjustment flexibility on site, the invention provides a vertical shaft impact crusher. The shaft-type iron-stone mixing chamber of the crusher can increase the wear of wear-resistant materials as little as possible in high-abrasion crushable materials, where traditionally only "rock-on-rock cavity" can be used, and achieve a similar "rock-on-iron cavity" The excellent crushing effect can make the whole crushing production line play the full capacity of other machinery and equipment, increase the output of final products, improve the output ratio of each final product, and make it more reasonable. It also provides on-site adjustment of height, front and rear position, and subsequent adjustment of height, thickness, and front and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com