Sand and powder separating device

A separation device and sand powder technology, which is applied in the direction of solid separation, separation of solids from solids with air flow, and filtration and sieving, can solve the problem of low efficiency of sand powder separation, and achieve high sand and gravel screening efficiency and high practicality performance, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

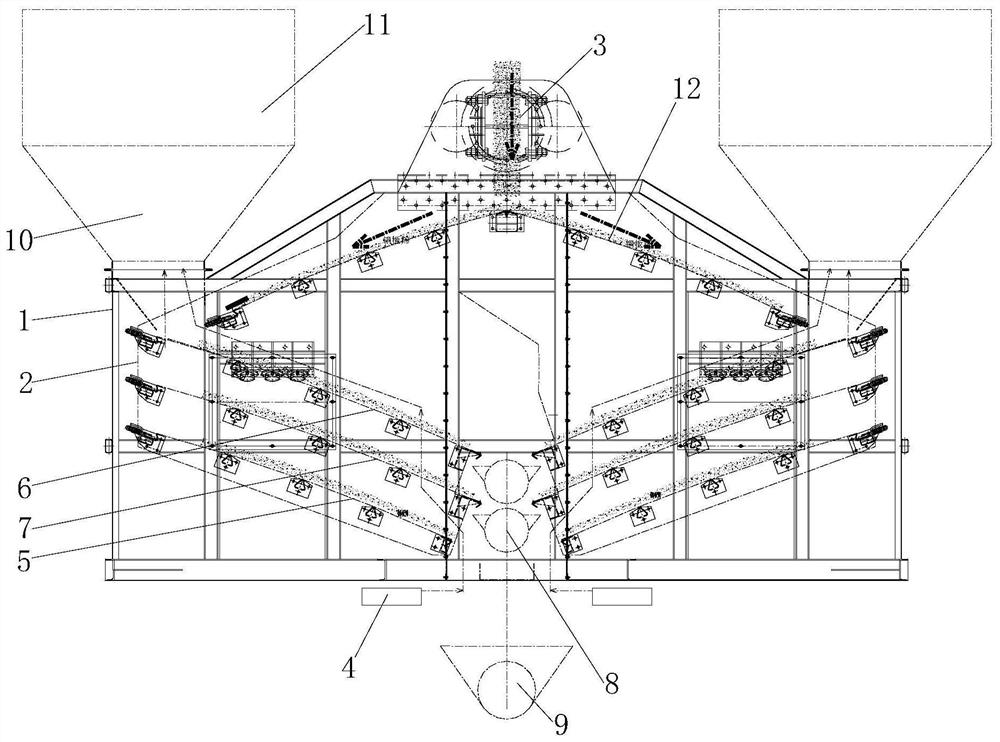

[0022] like figure 1 As shown, the present embodiment provides a sand powder separation device, including a body 1, a vibration cavity is provided in the body 1, a floating vibration support 2 is provided in the vibration cavity, and the vibration support 2 is equipped with The vibrating mechanism adopts a flexible connection between the vibrating support 2 and the body 1, specifically through a spring connection, that is, the top, bottom and surroundings of the vibrating support 2 are connected with the inner wall of the vibrating cavity by springs, so that the vibrating support 2 can be used in the vibrating cavity. Float up and down left and right to realize the vibration function of the vibrating support 2. The vibrating mechanism can adopt the structure of a motor and an eccentric wheel, and the vibrating mechanism is used to drive the vibrating support 2 to vibrate.

[0023] A screening mechanism is provided on the vibrating support 2, and the screening mechanism is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com