UFO target

A flying saucer and target blank technology, applied in the field of environmental protection flying saucer target, can solve the problems of non-environmental protection, high energy consumption, increased product cost, etc., and achieve the effects of good growth, low stone powder content, and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

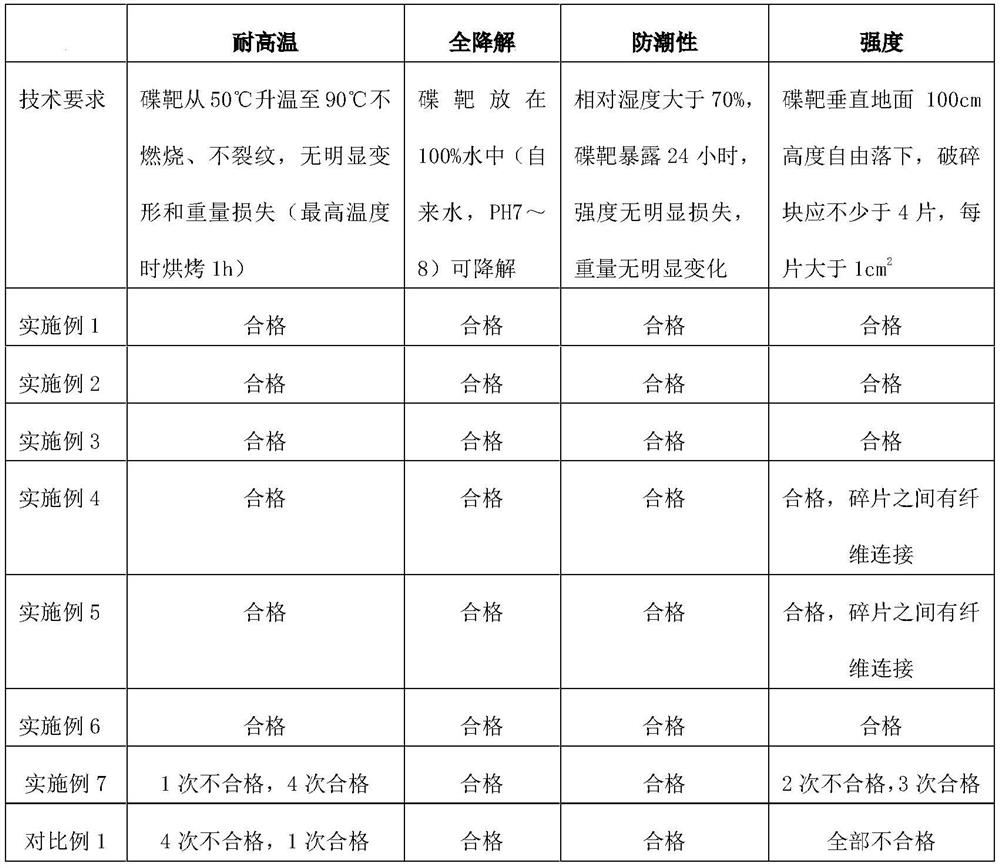

Examples

preparation example Construction

[0047] In a specific embodiment, the preparation method of the flying saucer target comprises:

[0048] a. Mix clay and stone powder, and stir at 1000-1500 r / min for more than 30 minutes to obtain mixture 1;

[0049] b. in step a, add pregelatinized starch, sodium carboxymethyl starch, micropowder silica gel, talc, magnesium stearate and the water of wetting amount to mix, and stir for more than 20min at 1000~1500 rev / min to obtain mixture 2 ;

[0050] c. molding the mixture 2 to obtain a flying saucer target blank;

[0051] d. The target blank of the flying saucer is obtained by drying it at 50~80℃ for 30~80min.

[0052] In a specific embodiment, step a is stirred at 1000-1200 rpm for 30-60 min.

[0053] In a specific embodiment, the molding in step c is vacuum extrusion molding.

[0054] The second technical problem to be solved by the present invention is to provide a preparation method of a flying saucer target.

[0055] In order to solve the second technical problem ...

Embodiment 1

[0068] a. Mix 600 g of 100-200 mesh clay and 200 g of 400-600 mesh stone powder, and stir at 1500 rpm for 40 minutes to obtain mixture 1;

[0069] b. in step a, add 100g of pregelatinized starch, 5g of sodium carboxymethyl starch, 3g of 800-1000 purpose micropowder silica gel, 10g of 1500-1800 purpose talcum powder, 4g of magnesium stearate and the wetting amount of water to mix, Stir at 1200 rpm for 20 min to obtain mixture 2;

[0070] c. Extruding the mixture 2 to obtain a flying saucer target blank;

[0071] d. Dry the flying saucer target blank at 50-60° C. for 40 minutes to obtain the flying saucer target.

Embodiment 2

[0073] a. Mix 630 g of 100-200 mesh clay and 180 g of 400-600 mesh stone powder, and stir at 1500 rpm for 40 minutes to obtain mixture 1;

[0074] b. in step a, add 90g of pregelatinized starch, 5g of sodium carboxymethyl starch, 3g of 800-1000 purpose micropowder silica gel, 10g of 1500-1800 purpose talcum powder, 4g of magnesium stearate and the wetting amount of water to mix, in Stir at 1200 rpm for 20 min to obtain mixture 2;

[0075] c. Extruding the mixture 2 to obtain a flying saucer target blank;

[0076] d. Dry the flying saucer target blank at 50-60° C. for 40 minutes to obtain the flying saucer target.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com