Efficient peanut combine harvester

A technology for combine harvesters and peanuts, applied to harvesters, digging harvesters, agricultural machinery and implements, etc., can solve the problems of low separation rate, difficult fruit peeling, energy consumption, etc., to improve picking efficiency, Avoid low-yield, most economical results

Inactive Publication Date: 2019-04-02

临沭县东泰机械有限公司

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, most of the peanut harvesters in the prior art use a shovel-like structure to excavate the soil, and use a triangular digging shovel to scoop up the peanuts together with the soil. Most of the collection devices adopt the nail-toothed roller and concave plate structure. The peanut seedlings and fruits pass through the nail-toothed roller, and the peanut seedlings are moved by the nail ruler. The concave plate and the peanut seedlings are frictionally decelerated. Concave plate sieve leaks down and falls into storage unit

Although the device of digging peanuts with multiple sets of side-by-side triangular shovels is very effective, it will consume a lot of energy to shovel up about 10cm of land, and it will also cause some peanuts to be shoveled. Since peanuts are mostly planted in rows, after starting the harvester , it is difficult for the machine to align the peanut ridges, resulting in some peanuts not being scooped up, and a small part of peanuts being left behind, which greatly reduces the yield

Moreover, the nail-tooth drum type separation device also has shortcomings. In actual use, due to the existence of soil, the friction between the peanut seedlings and the concave plate will be weakened, so that the nail teeth are difficult to peel off the fruit. The separation rate is not very high. Discarded along with the peanut seedlings, resulting in waste

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0030] As another specific embodiment of the present application, the engine 10 is also used to drive the circular tube grain raiser 1 , the hoist 6 and the cleaning device 7 to work.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

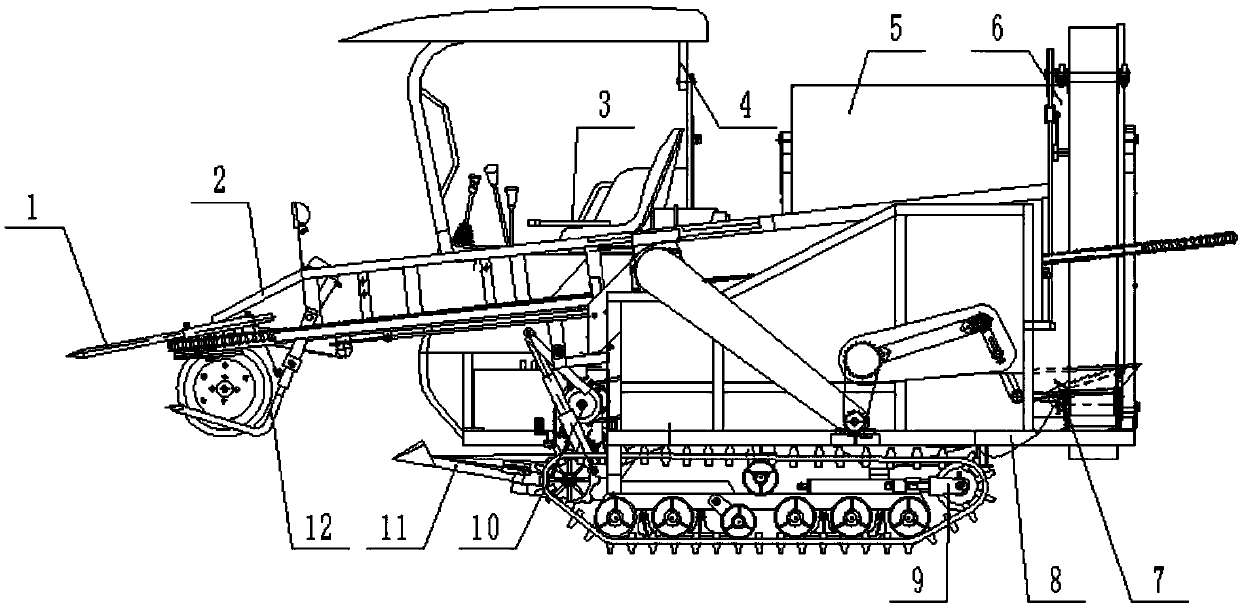

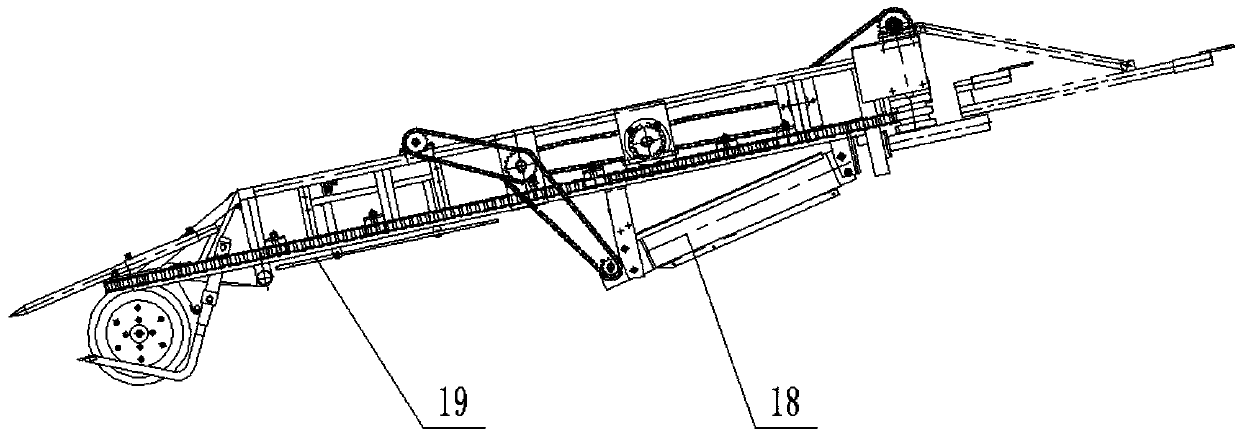

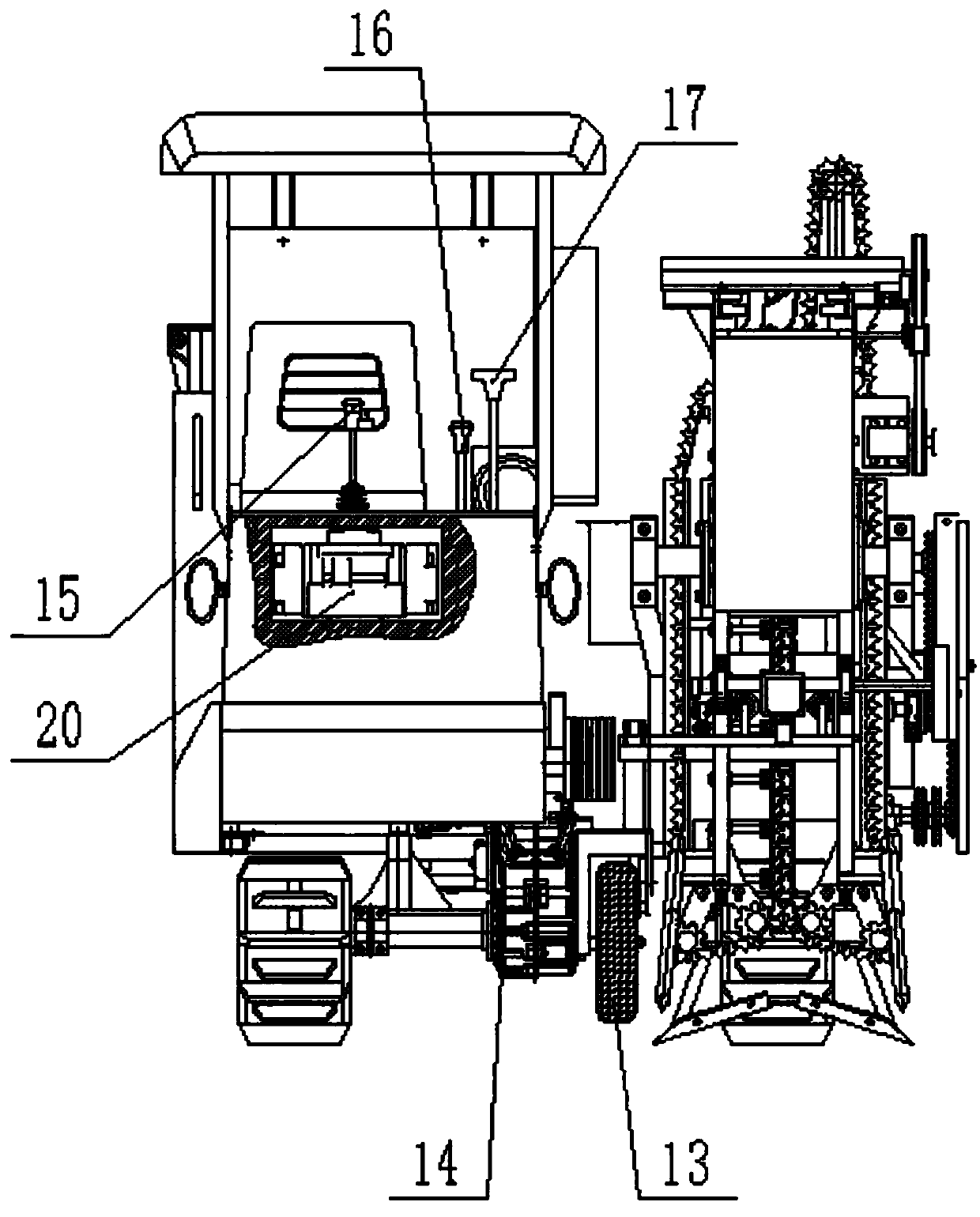

The invention belongs to the field of needle selectors and discloses an efficient peanut combine harvester which comprises a harvesting mechanism mainframe, a round-pipe grain lifter, a soil shaking mechanism, a pair roller differential phase fruit picking roller arranged on the harvesting mechanism mainframe, a ploughing blade arranged on the lower side of the front end of the harvesting mechanism mainframe, a seedling separator arranged on the lower side of the front end of a rack, a cleaning device arranged on the lower side of the rear end of the rack, a fruit collection box arranged abovethe cleaning device, a lifter arranged on the upper side of the cleaning device, a chassis arranged at the lower end of the rack and a traveling mechanism arranged at the lower end of the chassis ofthe rack. The efficient peanut combine harvester is simple in structure and can effectively avoid the problems of low yield and low peanut harvesting rate in the prior art.

Description

technical field [0001] The invention relates to the technical field of harvesters, in particular to a high-efficiency peanut combine harvester. Background technique [0002] There are many types of agricultural harvesters, but those specially used for harvesting peanuts are not common. With the development of agriculture and agricultural machinery in recent years, peanut harvesters suitable for large-scale peanut production and harvesting have gradually become agricultural needs. However, most of the peanut harvesters in the prior art use a shovel-like structure to excavate the soil, and use a triangular digging shovel to scoop up the peanuts together with the soil. Most of the collection devices adopt the nail-toothed roller and concave plate structure. The peanut seedlings and fruits pass through the nail-toothed roller, and the peanut seedlings are moved by the nail ruler. The concave plate and the peanut seedlings are frictionally decelerated. The concave screen holes l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01D29/00A01D33/08A01D33/02A01D33/00

CPCA01D29/00A01D33/00A01D33/02A01D33/08

Inventor 王青华丁付杰张为波闫昂昂李军浩

Owner 临沭县东泰机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com