Rod chain and side backward inclined vibrating screen combined residual film recovery machine

A vibrating screen and combined technology, applied in the field of residual membrane recycling machine, can solve the problems of low production efficiency, low vibration conveying efficiency, insufficient residual membrane and soil separation ability, etc., so as to reduce soil content and reduce the load of membrane soil separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

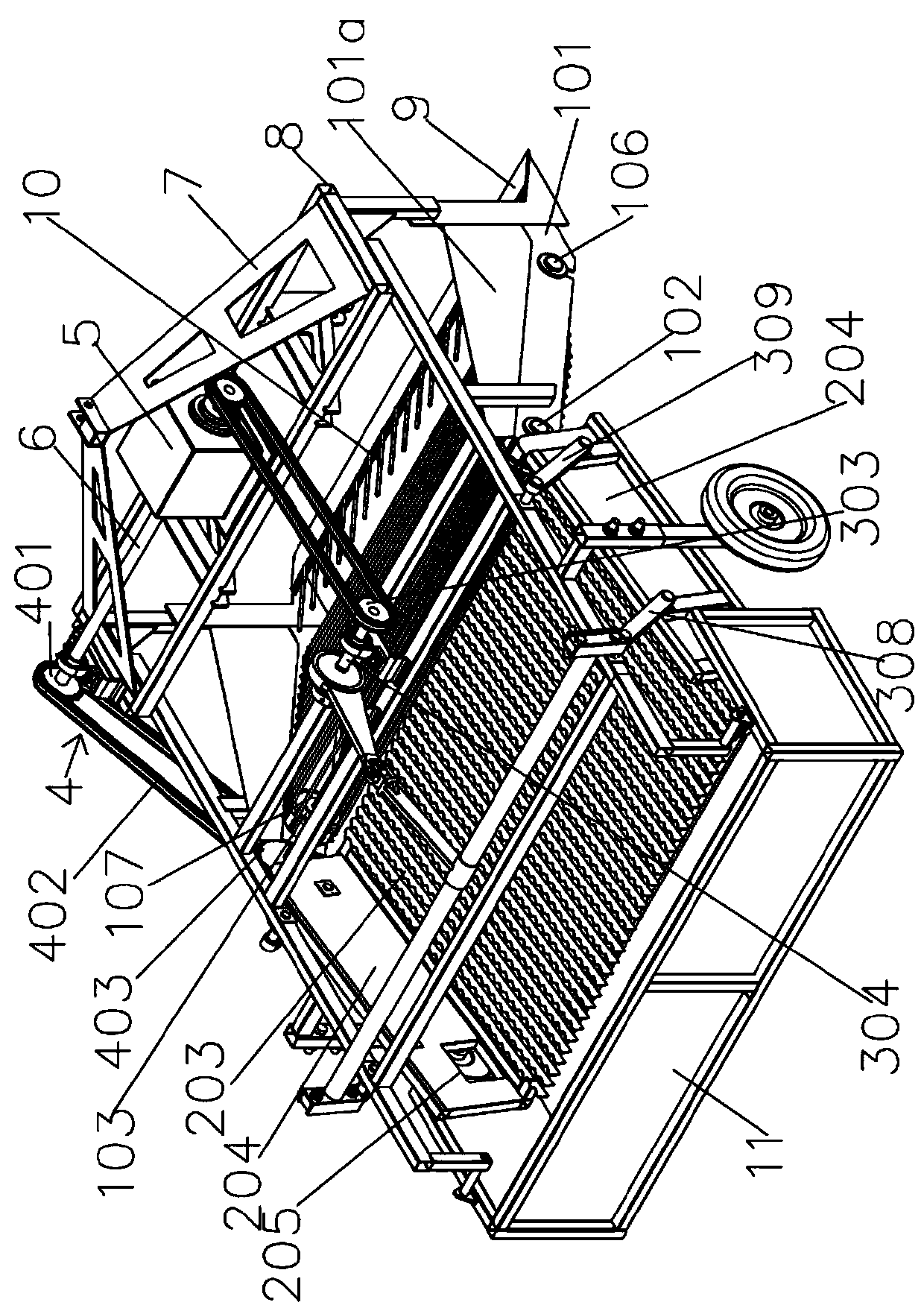

[0046] The present invention will be further described below in conjunction with the drawings and specific embodiments.

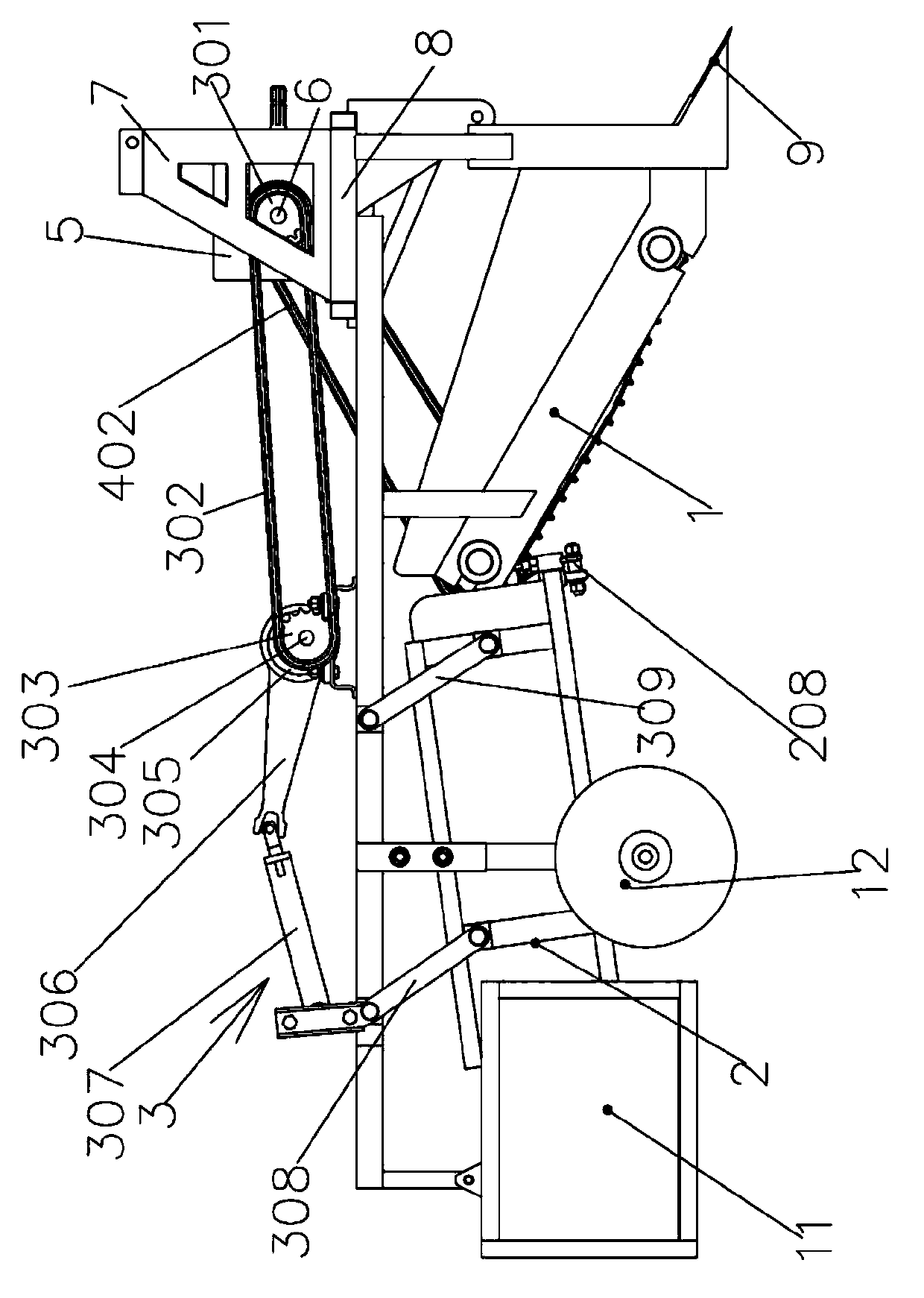

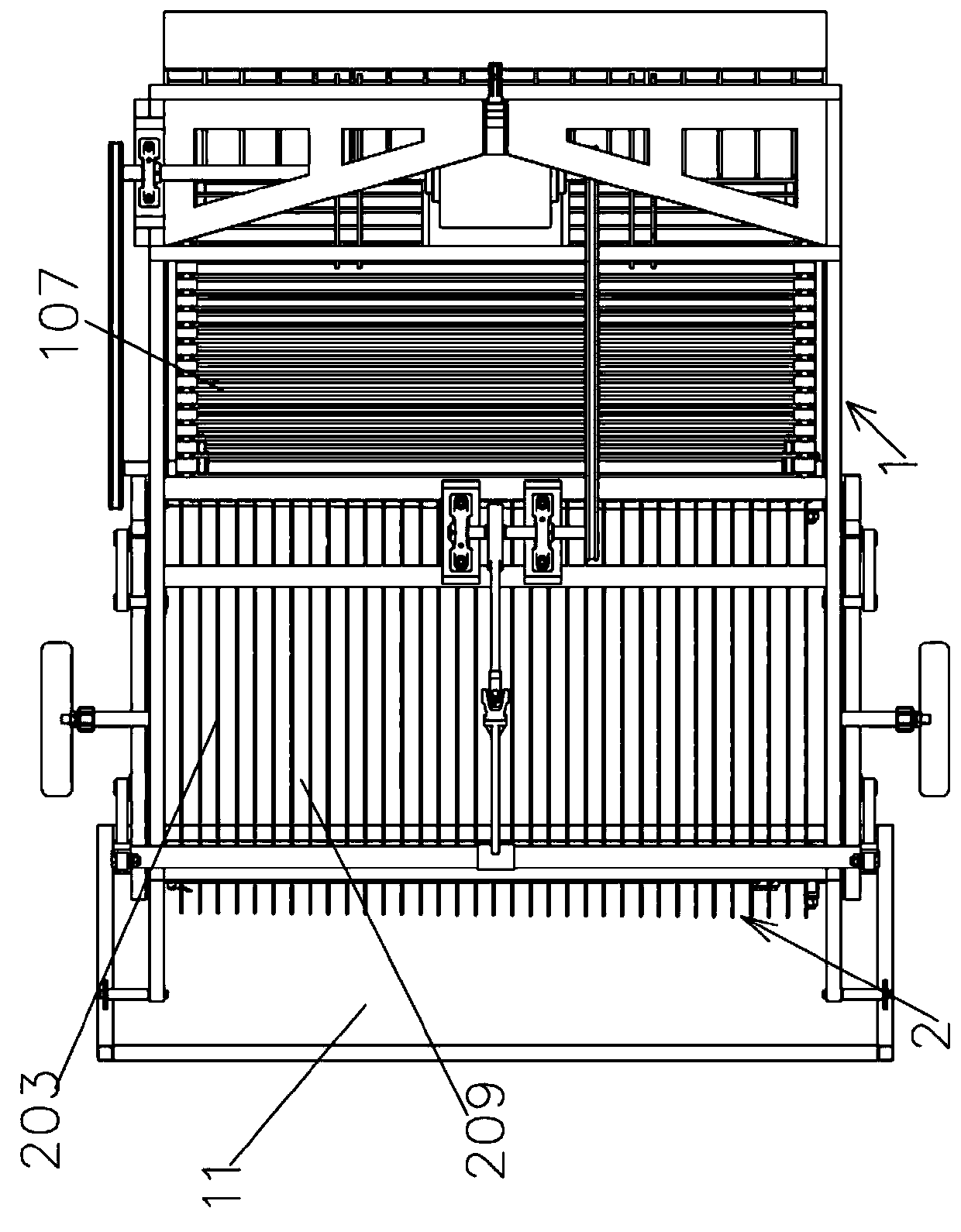

[0047] Such as Figure 1-3 As shown, a combined type residual film recovery machine with a rod chain and a laterally tilted vibrating screen includes a frame 8 and a drive system, as well as an excavating shovel 9 and a membrane-soil separation component which are sequentially installed on the frame 8 from front to back , Film collection basket 11; Among them, the drive system includes a gearbox 5, a power output shaft 6, a three-point suspension 7 fixed to the frame 8, the three-point suspension 7 is connected to the tractor body, and the power input side of the gearbox 5 In cooperation with the tractor power unit transmission, the power output shaft 6 is installed on the power output side of the gearbox 5 and rotates the wear frame 8. The power output shaft 6 is arranged transversely along the width direction of the tractor.

[0048] The above-mentioned membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com