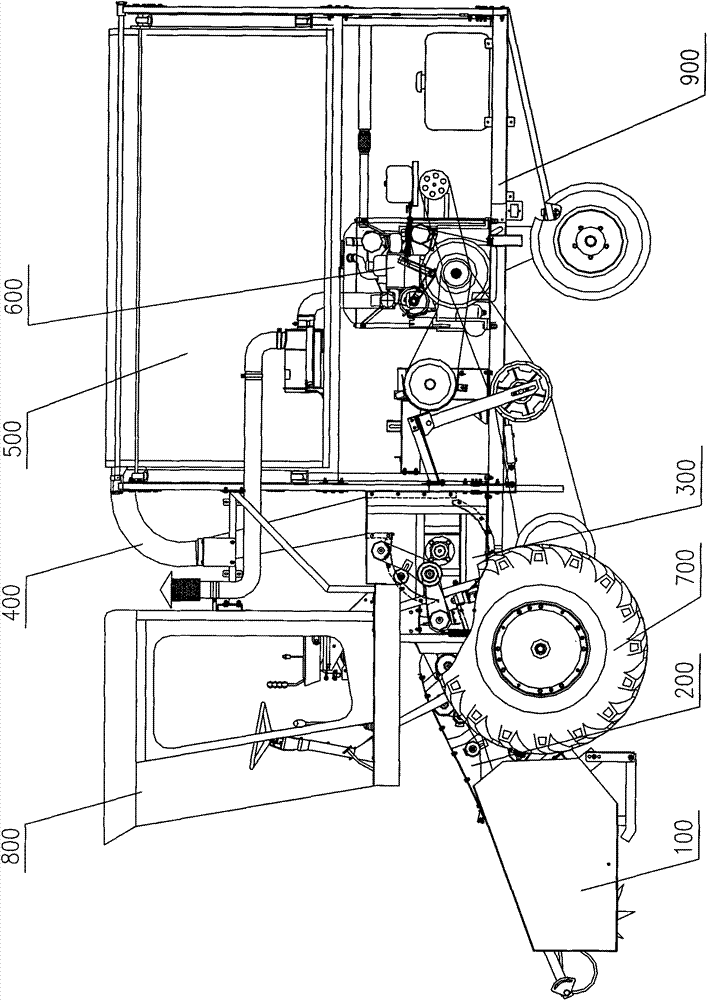

Straw harvesting method and straw harvesting machine

A harvesting method and harvester technology, which is applied to harvesters, loaders, crop processors, etc., can solve problems such as not being able to handle straw, and achieve the effects of compact structure, high harvesting efficiency, and deep plowing and sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0162] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments to further understand the purpose, solutions and effects of the present invention, but not as a limitation of the protection scope of the appended claims of the present invention.

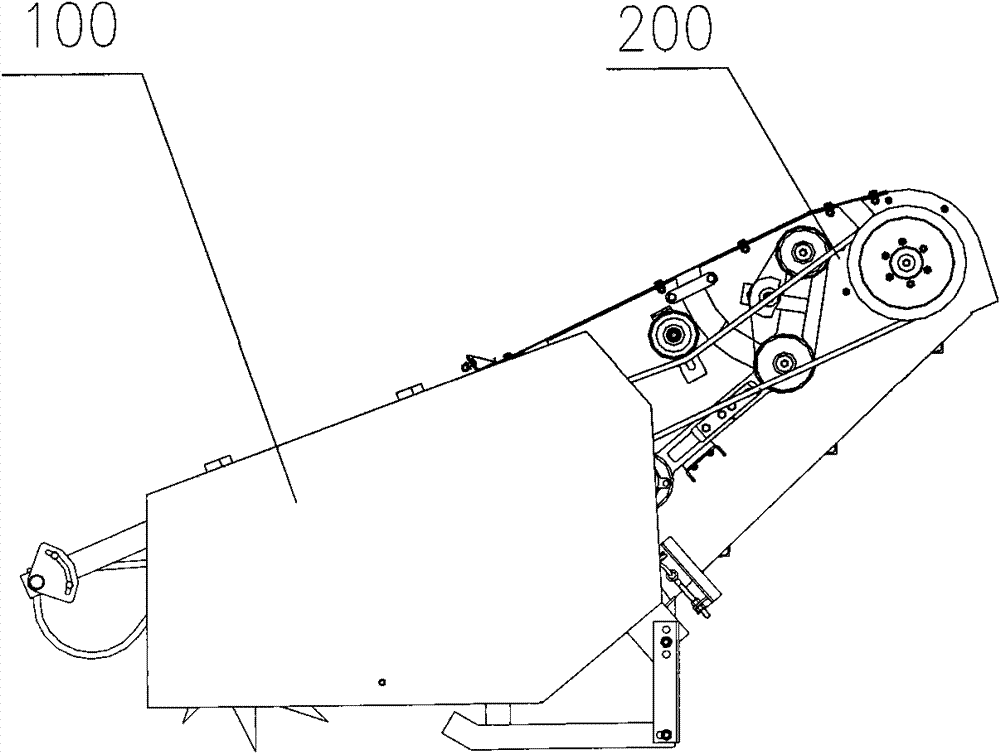

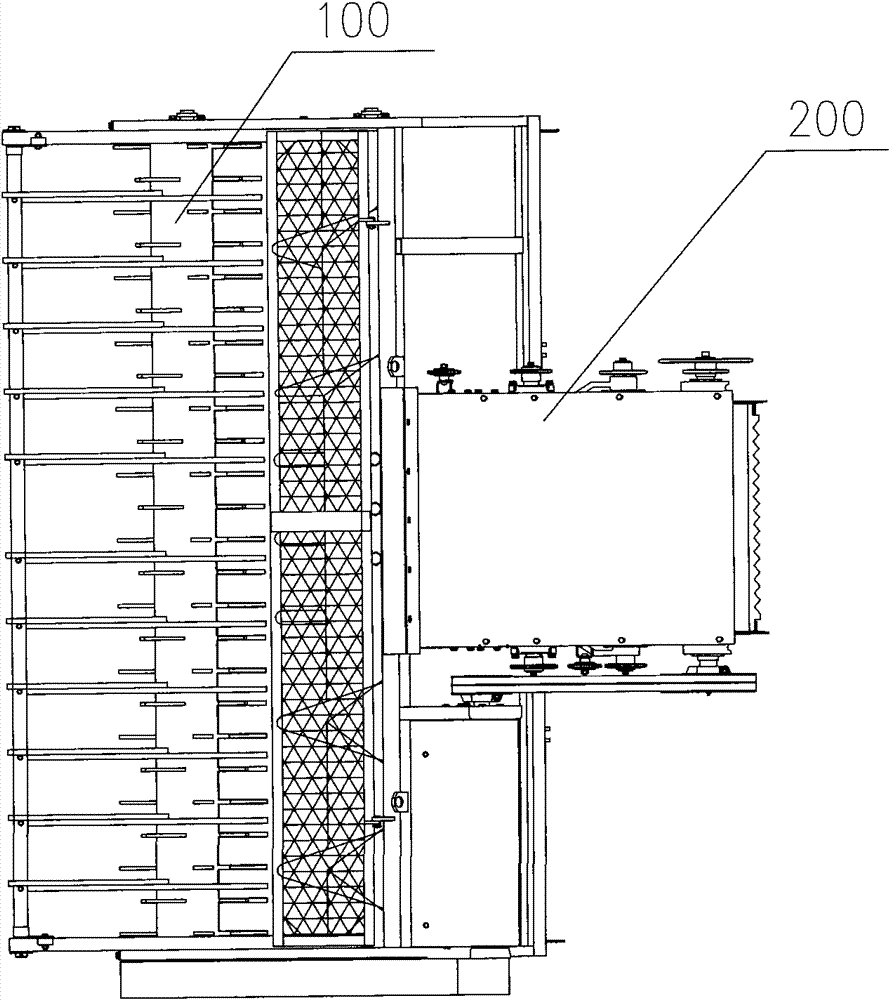

[0163] The straw harvesting method of the present invention is mainly used for harvesting the straw that has been pulled down on the ground, especially for harvesting the straw of crops such as cotton and dwarf shrubs. It includes a picking step, a conveying step, a chopping step, and a fine throwing. 料 steps. Among them, the picking step is used to pick up the straw that has been pulled down on the ground. In the picking step, there is also a step of agitating the picked straws in a centralized position; the conveying step is used to pick up and agitate the Concentrated straws are transported to the shredder. In this transporting step, there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com