Novel oilseed rape harvester

A harvester and rapeseed technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of not being suitable for large-scale combine harvesters, the effect is not too ideal, and the rapeseed particles are small, saving manpower and material resources. , Adjustable, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

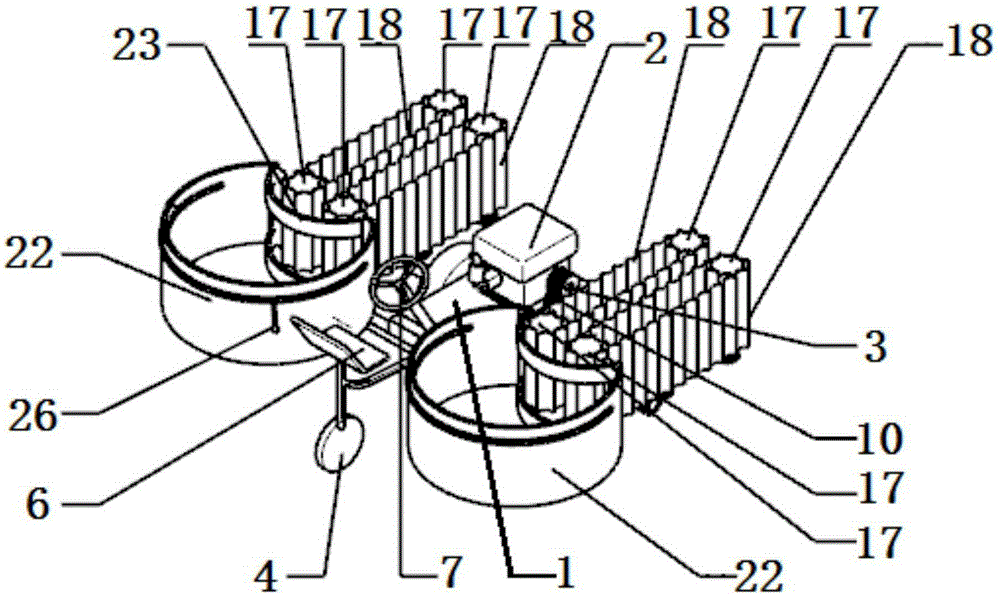

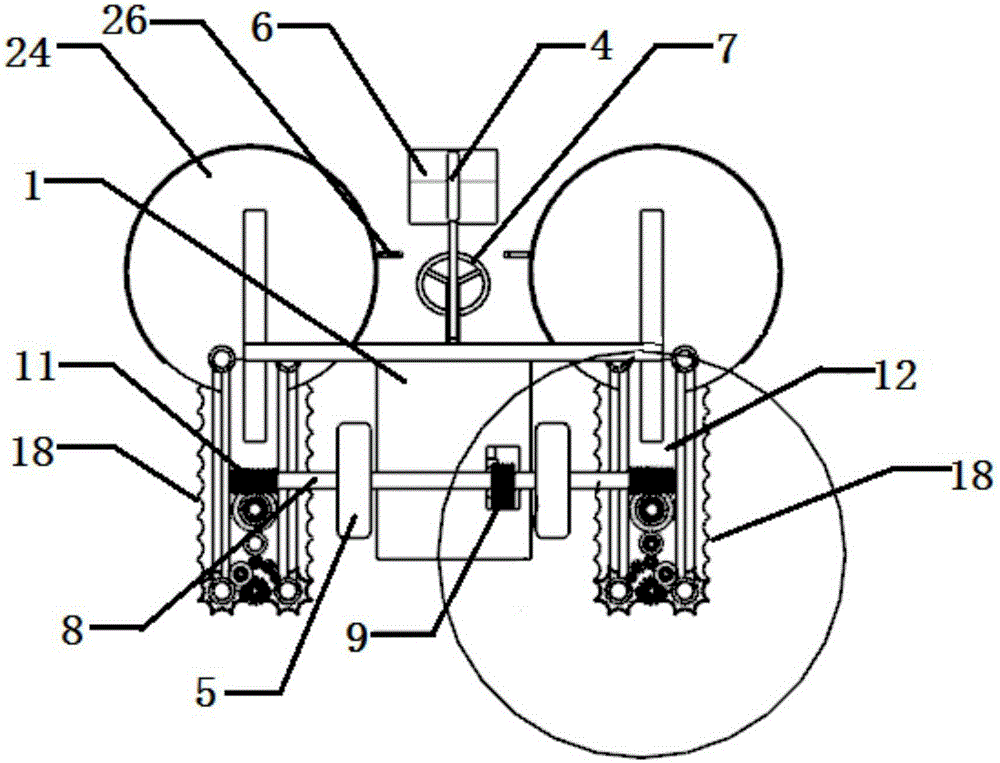

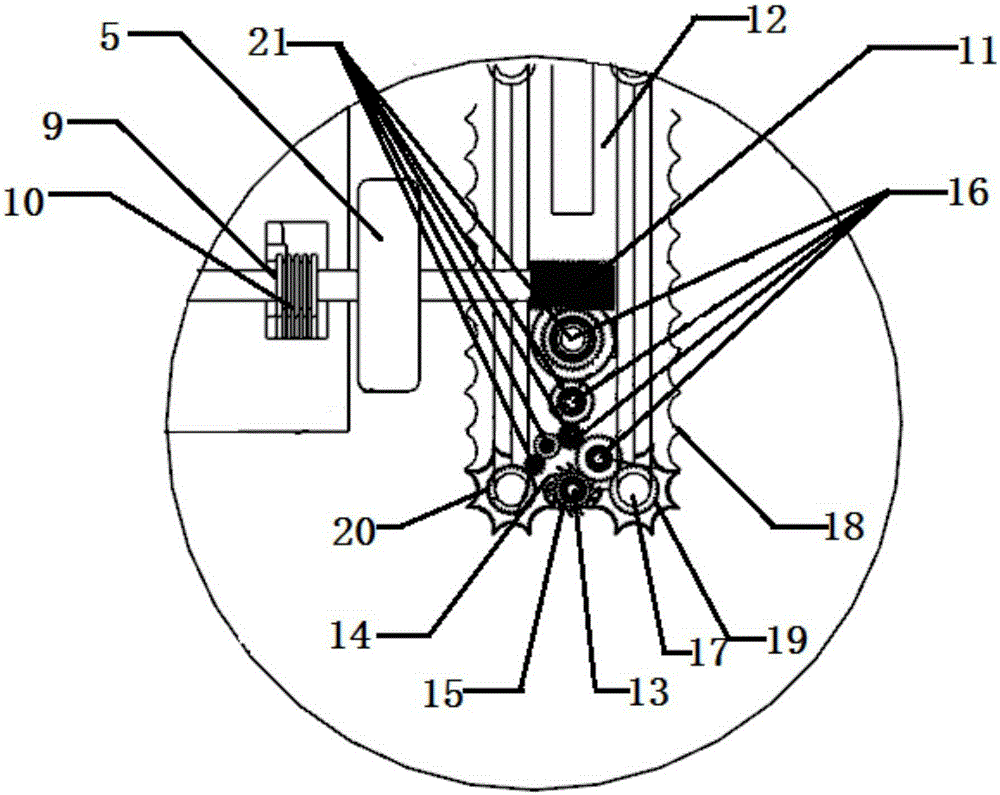

[0027] Example: refer to Figures 1 to 6 As shown, a new type of rapeseed harvester includes a frame 1, a power mechanism and a walking mechanism located on the frame 1, and two groups of harvesting devices, a transmission device and a beating device that are sequentially arranged on the frame 1 from front to back. bundle device.

[0028] The power mechanism of the present invention comprises a diesel engine 2 arranged above the frame 1, and a belt pulley-3 connected with the output end of the diesel engine 1.

[0029] The traveling mechanism of the present invention comprises a rear traveling wheel 4 arranged below the frame 1, two symmetrical front traveling wheels 5 arranged below the frame 1, and a rear traveling wheel 5 arranged on the frame 1 and positioned above the rear traveling wheel 4. Seat 6, and the steering wheel 7 that is located at the front side of seat 6; Two front side travel wheels 5 are sleeved on the worm shaft 8, and the belt pulley 2 9 is set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com