Novel harvester

A harvester, a new type of technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of low efficiency, capital occupation, and many types of models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

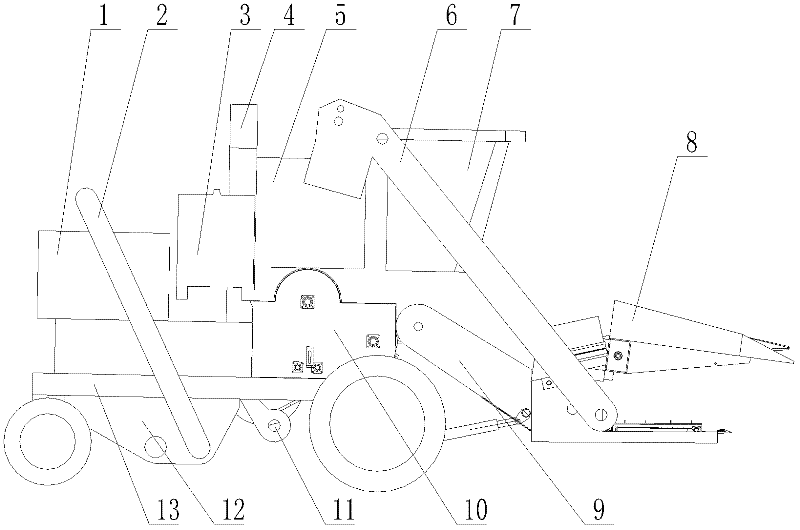

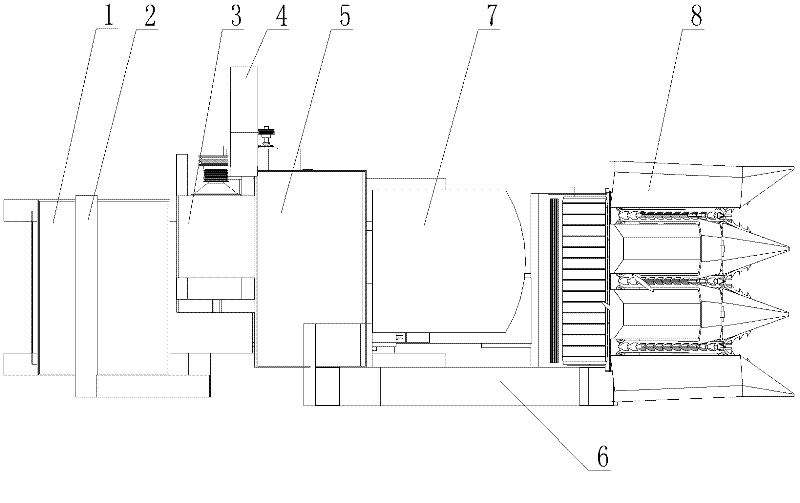

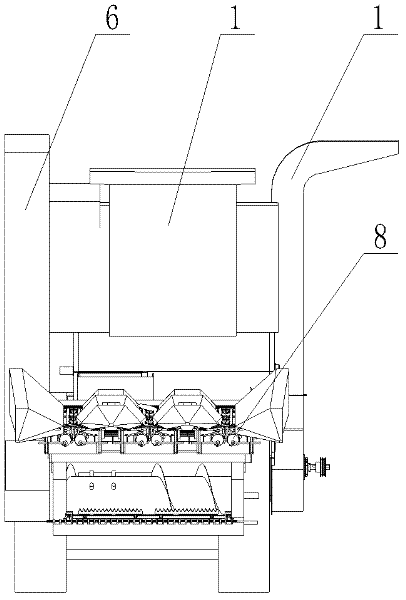

[0020] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. The present embodiments are descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

[0021] The following is an example of a corn harvester:

[0022] A new type of harvester, comprising a grain bin 1, a vehicle 13, a grain cleaning device 12, a cleaning fan 11, a straw and grain separation device 10, a conveyor 9, a corn header 8, a corn elevator 6, and ear grain The tank 5, the engine 3, the grain conveyor 2, and the stem processing apparatus 4 are comprised, and the cab 7 is attached to a vehicle. The straw and grain separation device is fixed on the vehicle, the engine is fixed at the rear of the straw and grain separation device, the ear grain box is hinged on the upper part of the straw and grain separation device, and the grain grain box is hinged on the vehicle at the rear of the engine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com