Cutting and throwing device for self-propelled intelligent peanut vine harvester and peanut vine harvesting method

A technique for peanut seedlings and harvesters, which is applied to digging harvesters, harvesters, cutting equipment, etc., can solve the problems of lowering feed quality, heavy equipment, complicated procedures, etc., saves the process of impurity screening, and reduces the weight of equipment , the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]In order to make the objects, technical solutions, and advantages of the present invention, a particular embodiment of the present invention will be described in conjunction with the accompanying drawings, which will become an example of the present invention. It does not constitute a limitation of the scope of the invention. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention without creative labor premise.

[0043] Further, in this paper, "and / or" herein is merely a correlation relationship to the associated object, indicating that there may be three relationships, such as A and / or B, which can be represented: Alone A, while there is A and B, There are three cases of B alone. In addition, the characters " / " in this article generally indicate that the front and rear association objects are a "or" relationship.

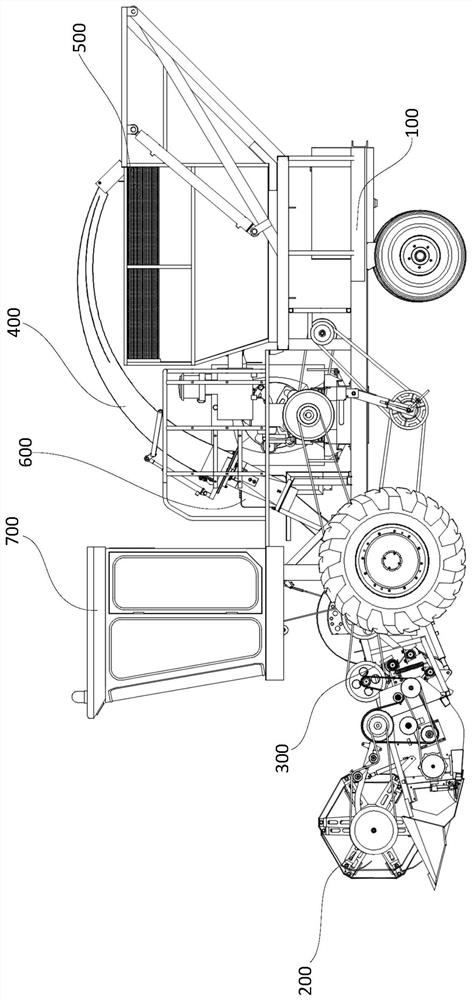

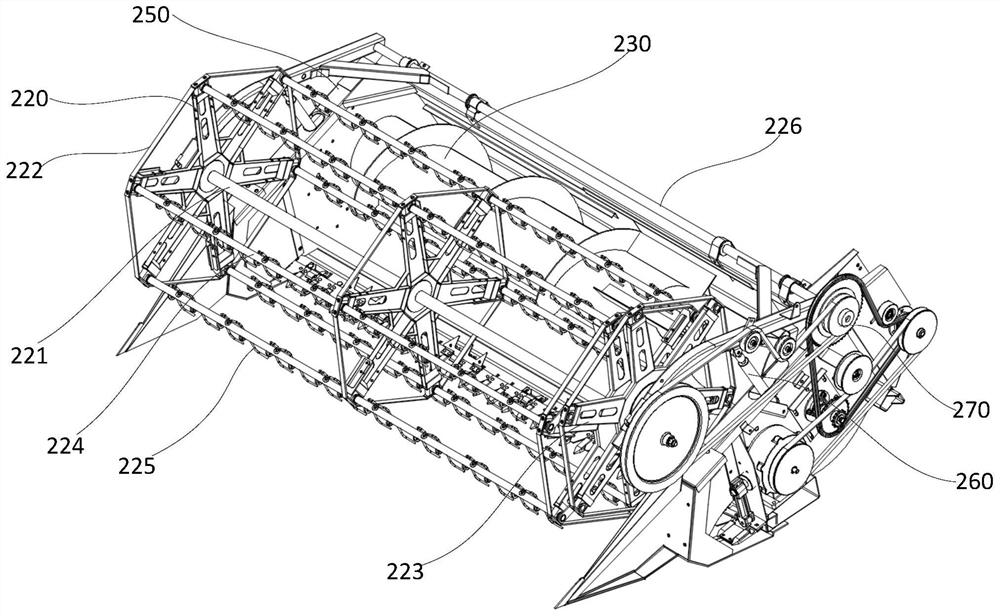

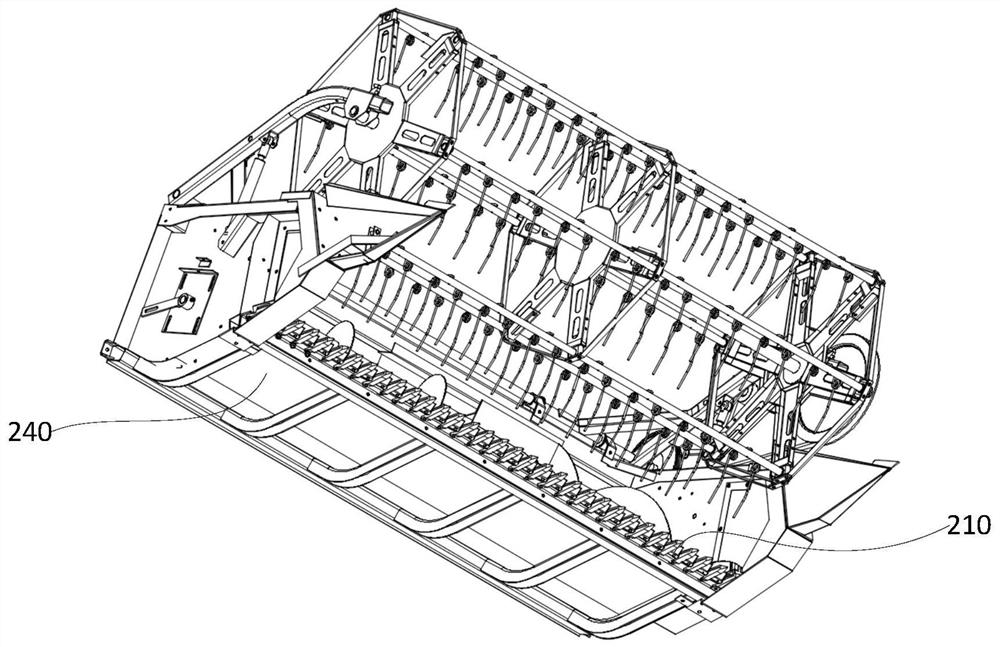

[0044] The self-propelled intelligent peanut seed harvester of the present e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com