Gathering type plastic film residue bundling and recovering machine

A recycling machine and residual film technology, applied in harvesters, agricultural machinery and implements, shovels, etc., can solve the problems of large residual film soil and impurities, production reduction, residual film recycling, etc., to improve the residual film recycling effect, overall Simple structure and ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

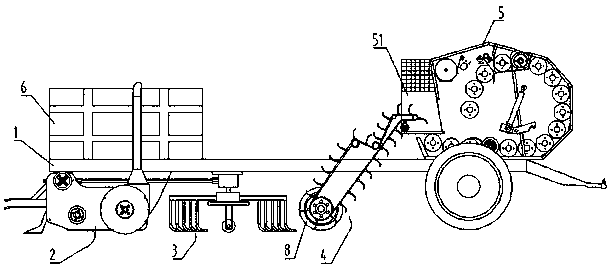

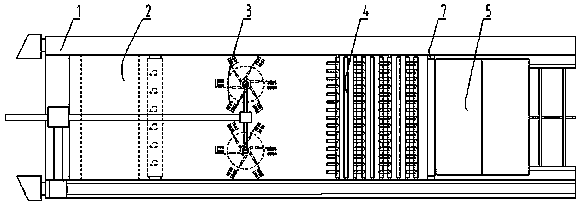

[0044] Embodiment 1: as Figure 1-8 As shown, a gathering-type bundling residual film recovery machine includes a frame 1, and a straw crushing and returning mechanism 2 for crushing and picking up straw and root stubble in the land is arranged on the frame 1 in sequence according to the working direction. A film gathering mechanism 3 for concentrating the agricultural film in the land and removing impurities, a residual film picking mechanism 4 for picking up the residual film, and a bundling device 5 for bundling the picked up residual film.

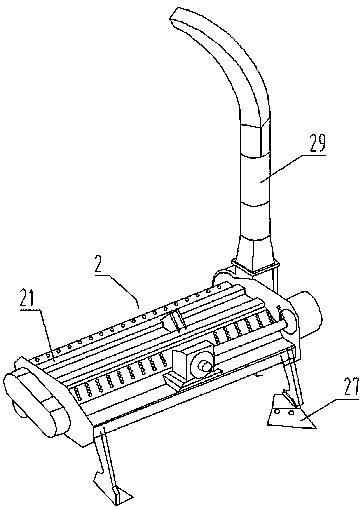

[0045] Such as Figure 1-5 As shown, the straw crushing and returning mechanism 2 includes a housing 21, a crushing knife shaft 22 is arranged in the middle of the housing 21, and an auger 24 is arranged behind the crushing knife shaft 22. The front of 21 is provided with the film device that is used to dig out the agricultural film buried in the ground on the ground surface, and the rear of described housing 21 is provided with the e...

Embodiment 2

[0109] Embodiment 2: as Figure 9-10 As shown, in the above-mentioned embodiment 1, the film wrapping mechanism 3 can also adopt Figure 9-10 As shown in the structure, the film wrapping mechanism 3 includes a mounting seat 31, and a rotating film wrapping device is arranged below the mounting seat 31, and the rotary film wrapping device is driven to rotate by a film wrapping driving device.

[0110] The rotating film holding device includes a rotating base arranged below the mounting base 31 , and a plurality of film holding arms 33 are evenly arranged in a ring on the outer surface of the rotating seat.

[0111] The position near the outer end of the film arm 33 is fixed with a plurality of film rakes 34 , and the plurality of film rakes 34 are evenly spaced along the length direction of the film arm 33 .

[0112] The membrane-wrapping driving device includes a transmission box 36 arranged above the rotating base and fixedly connected to the mounting base 31 , and the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com