Concrete production system

A production system and concrete technology, applied in clay preparation equipment, mixing operation control, mixing plant, etc., can solve the problems of concrete waste, non-environmental protection, etc., and achieve the effect of improving overall quality, increasing utilization rate, and reducing soil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

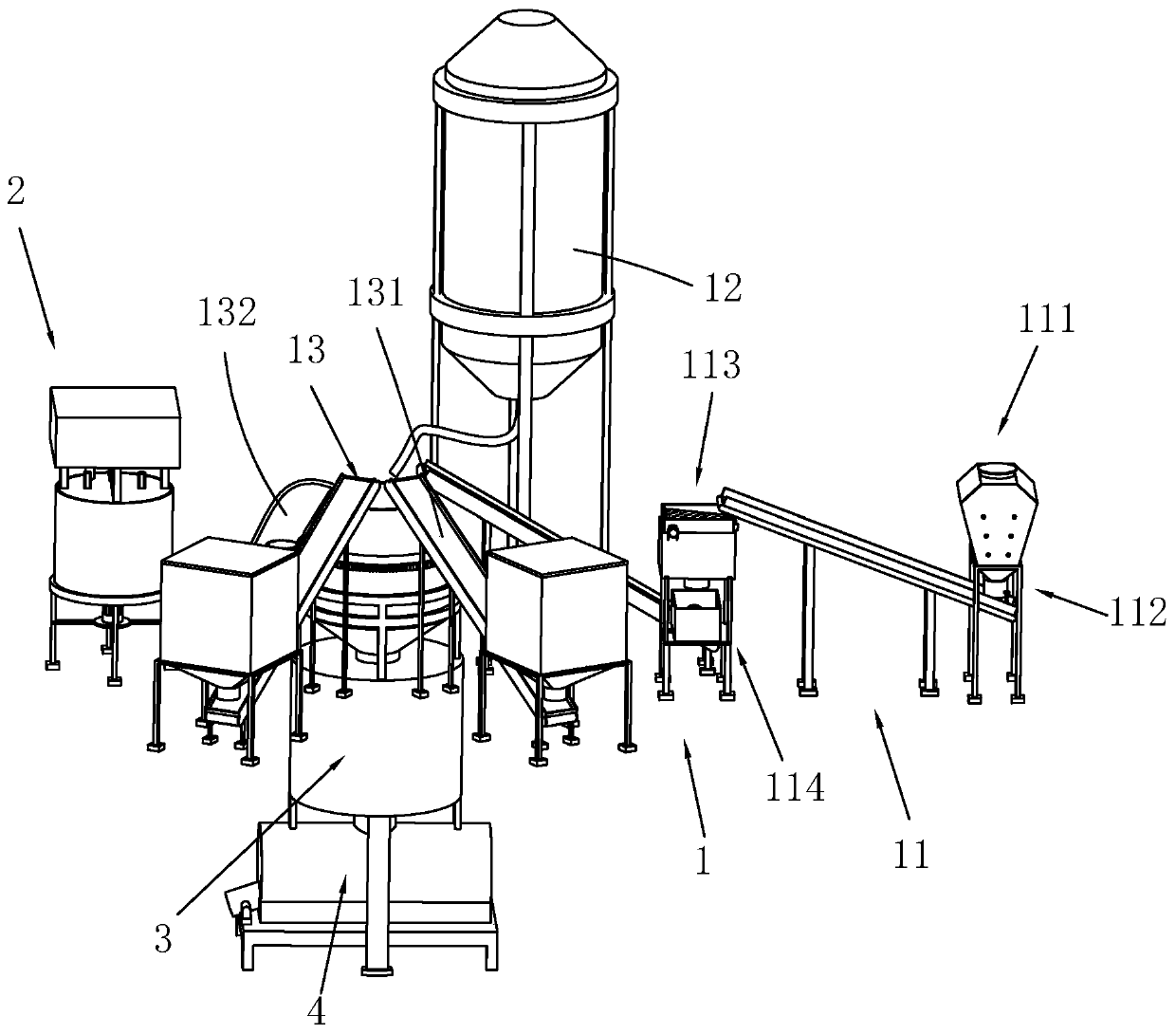

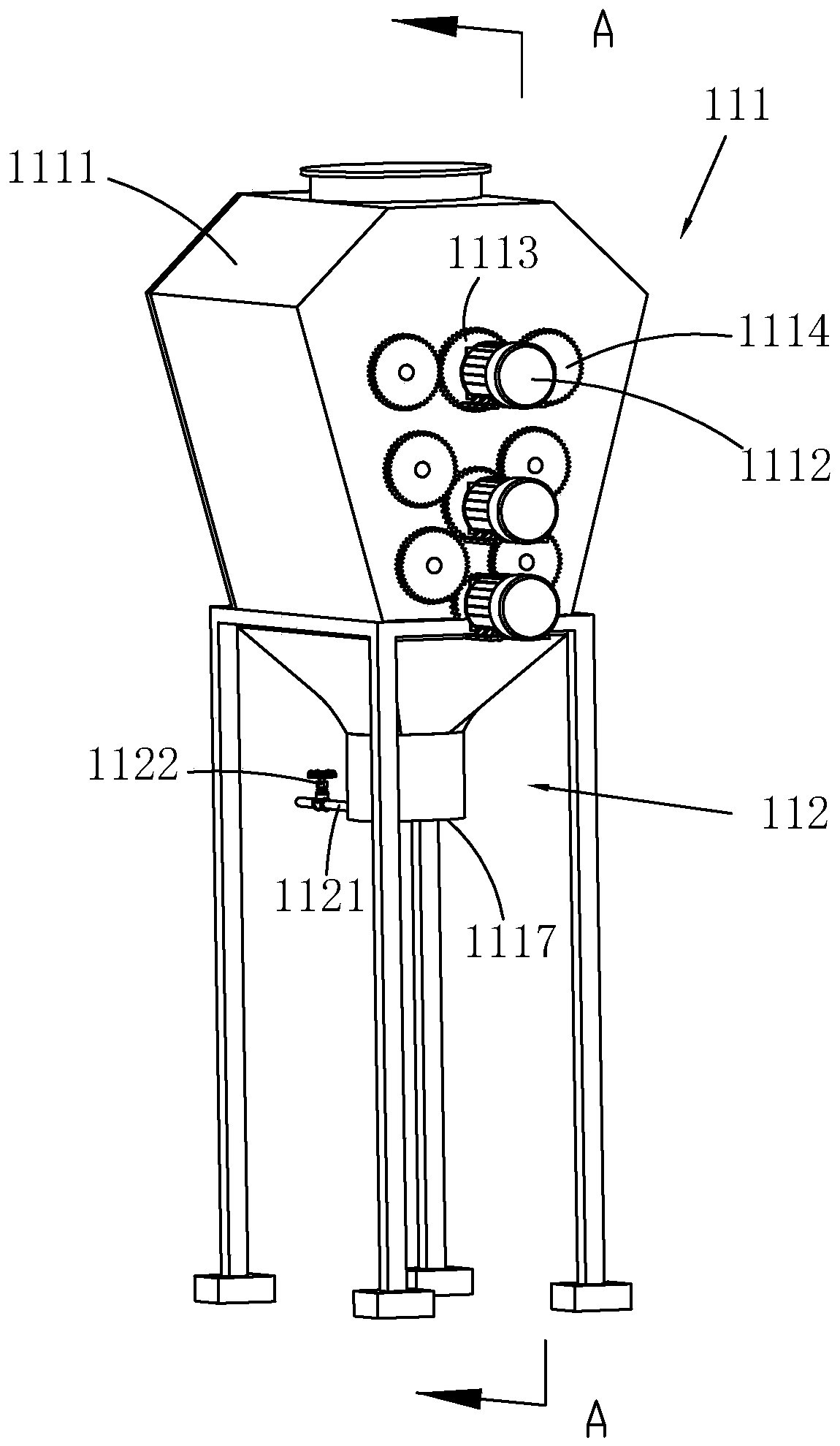

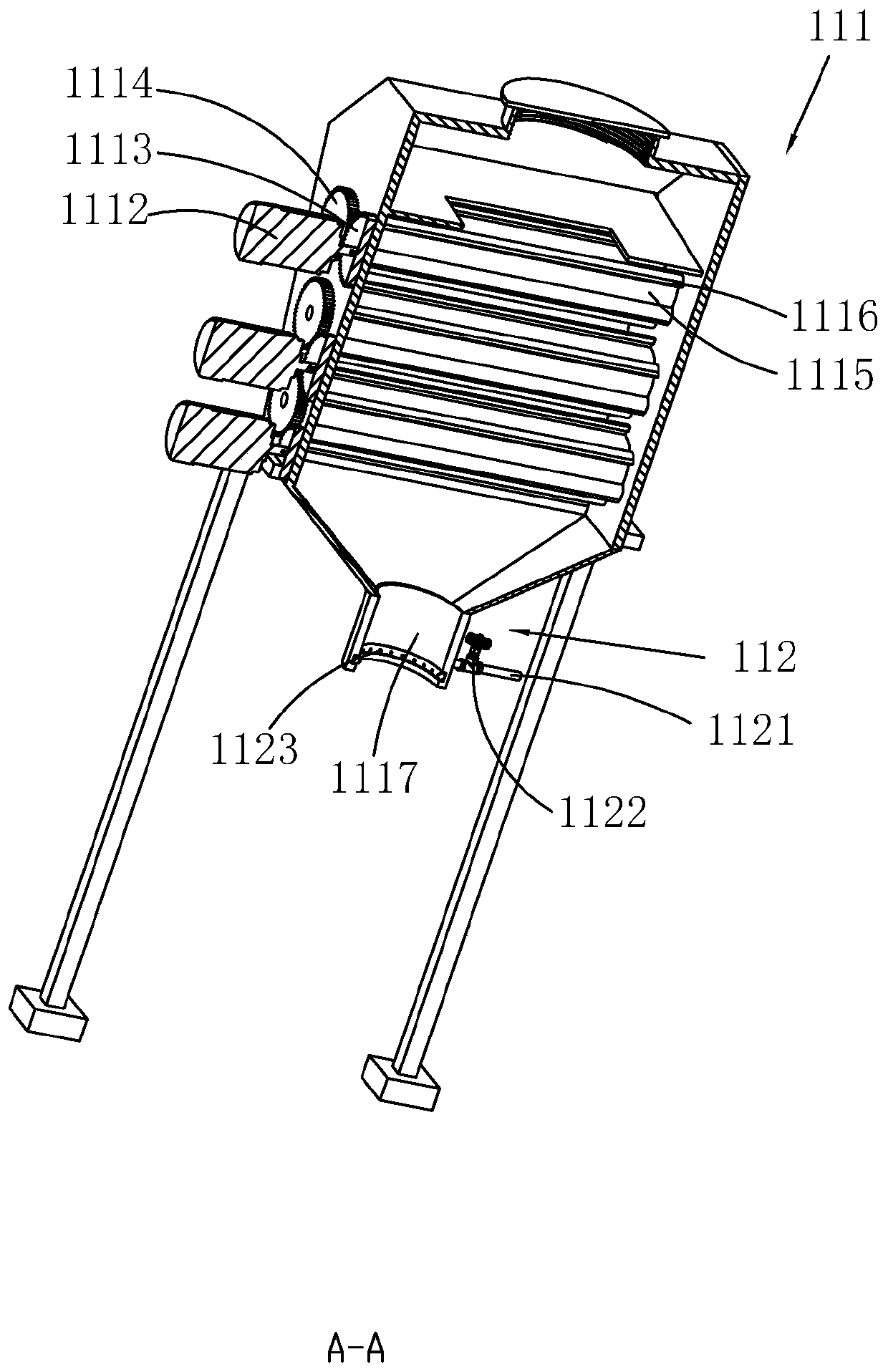

[0040] Such as figure 1 As shown, a concrete production system includes a feeding device 1 and a stirring device 3. The feeding device 1 includes a sand and gravel feeding device 131, a cement feeding device 121 and a recycled concrete feeding device 111, and the sand and gravel feeding device 131 , The cement feeding device 121 and the recycled concrete feeding device 111 are connected to the stirring device 3 , the water supply device 2 is arranged above the stirring device 3 , and the discharging device 4 is arranged below the stirring device 3 . Add sand, stones, finished recycled concrete, cement, water and admixtures into the mixing device 3 for concrete preparation.

[0041] Such as figure 1 As shown, the sand and gravel feeding device 131 includes a sand supply conveyor belt 131 connected to the sand storage bin and a stone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com