A pick-up device and a collection device using the pick-up device

A collection device and picker technology, applied in the field of pickers and collection devices, can solve the problems of equipment wear, leakage rate and high soil content of straw bales, so as to reduce fuel consumption, save manpower and picking time, and reduce soil content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

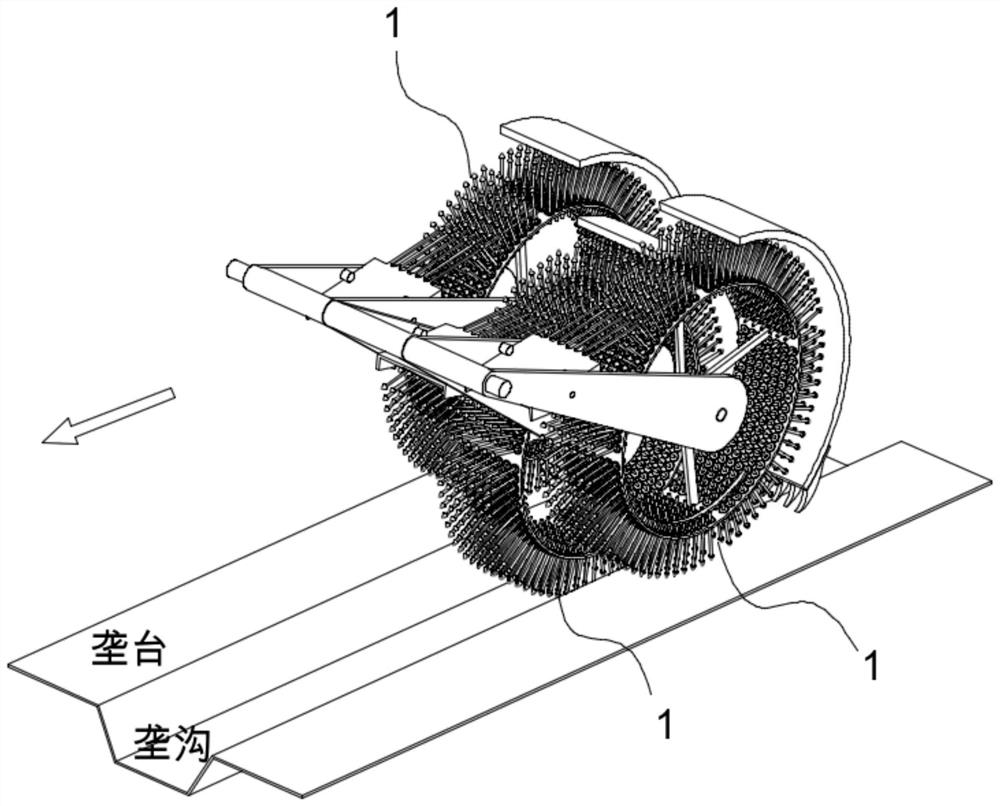

[0048] The invention relates to a picker, which picks up agricultural wastes waiting to be picked up from the ground by means of clamping, piercing, etc. The type pickup relies on the high-speed rotating horizontal spring teeth to exert kinetic energy on the ground to be picked up, so that it bounces off the ground and achieves the pickup effect by hooking and belting.

[0049] The pickup includes an annular motion mechanism 1, the annular motion mechanism 1 includes a pickup ring and a pickup needle 12, the pickup ring is the main structure of the pickup, and its outer contour can be circular or non-circular. In the case of non-circular shapes, polygons, etc., the regularly arranged ridges and ridges form a catenary, so that the non-circular pick-up ring moves smoothly on the catenary, which can realize the non-ridge operation of the picker. When it is in shape, the ridge alignment operation of the picker can be realized. The pick-up needle 12 is arranged on the outer periph...

Embodiment 2

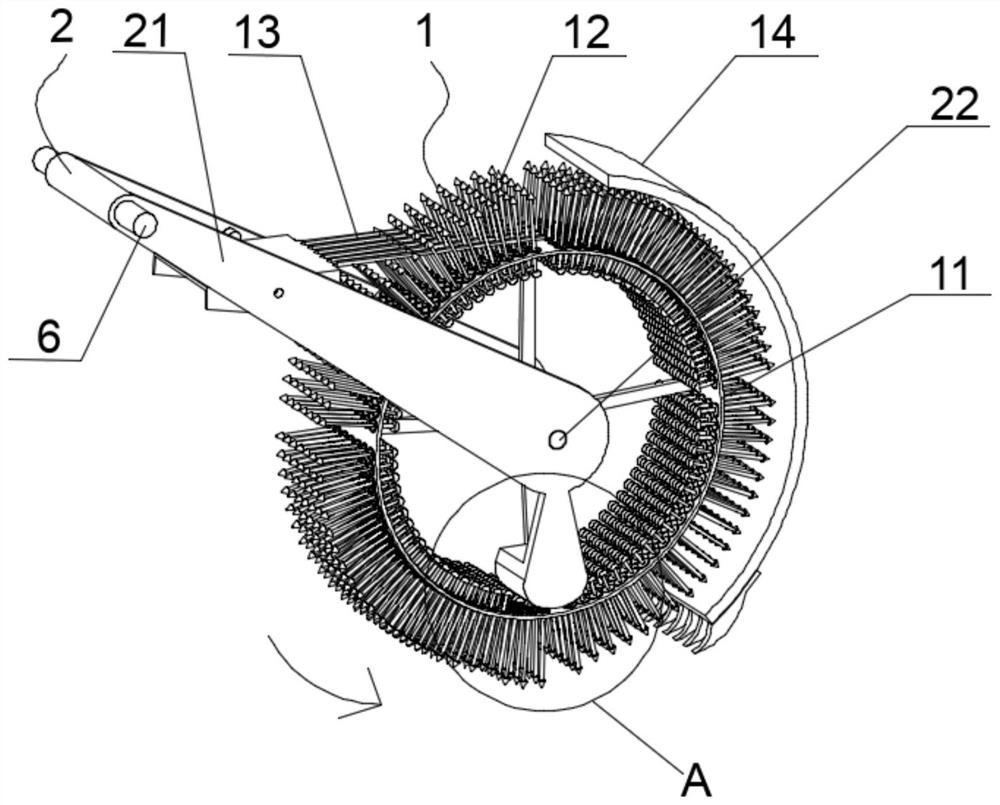

[0053] The pickup ring in this embodiment adopts the structure of pickup wheel 11 .

[0054] like image 3 As shown, the annular motion mechanism 1 is rotatably mounted on the pickup mounting frame 2 around the axis. The annular motion mechanism 1 includes a pickup wheel 11 and a pickup needle 12. The pickup wheel 11 is composed of a rim, a hub and spokes. The rim is concentrically sleeved on the outer side of the hub, the spokes are evenly installed between the rim and the hub in the circumferential direction, and the rim can adopt a continuous arc curve or multiple discontinuous arc curves.

[0055] The hub of the pickup wheel 11 is sleeved on the connecting shaft 22 of the pickup mounting frame 2 and rolls toward the object to be picked up. The pickup mounting frame 2 includes two symmetrically arranged support arms 21 and fixed on the two support arms 21. The connecting shaft 22 between them, the upper ends of the two support arms 21 are sleeved on the fixed shaft 6 at th...

Embodiment 3

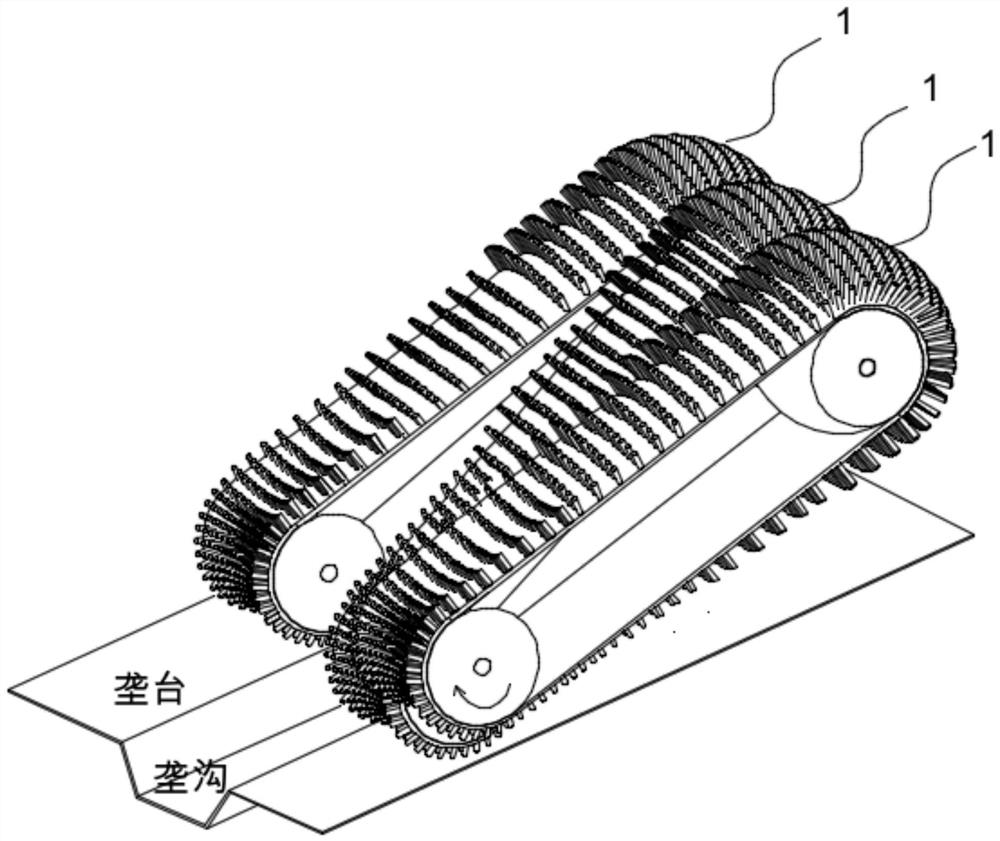

[0059] The pickup ring in this embodiment adopts an endless belt structure.

[0060] like Figure 4 As shown, the annular motion mechanism 1 includes two pick-up wheels 11, a pick-up needle 12 and a belt 15. The two pick-up wheels 11 are an expansion wheel 111 and a tightening wheel 112, respectively. The belt 15 is expanded and tightened between the expansion wheel 111 and the on the take-up wheel 112. The take-up wheel 112 is used to pick up the objects to be picked up on the ground and attach them to the belt 15 to form attachments. Preferably, the take-up wheel 112 is installed on the side of the pickup mounting frame 2 close to the ground and suspended above the ground, and the take-up wheel 112 is a cylindrical shape with a diameter in the middle portion smaller than that at both ends. Preferably, the diameter of the middle of the tightening wheel 112 is 0.3-0.6 times the diameter of the two ends. The expansion wheel 111 is used to release the picked up attachments. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com