Corn harvester equipped with corn straw cutting, smashing, recovering, concentrated placing and strip laying device

A corn harvester and straw crushing technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as difficult environment, pollution, reduce soil content, etc., achieve reasonable overall structure, reduce soil content, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

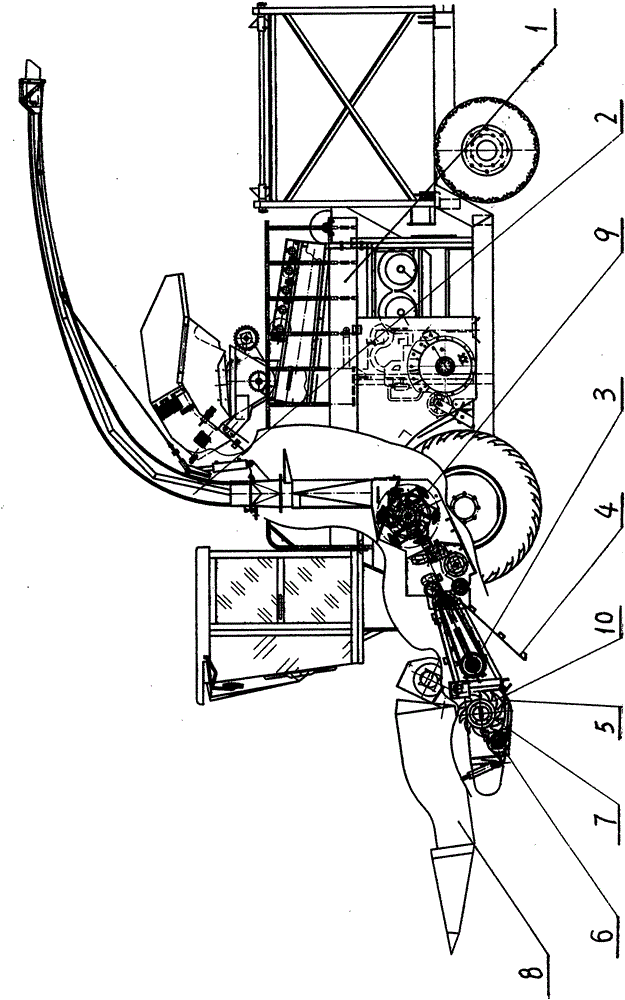

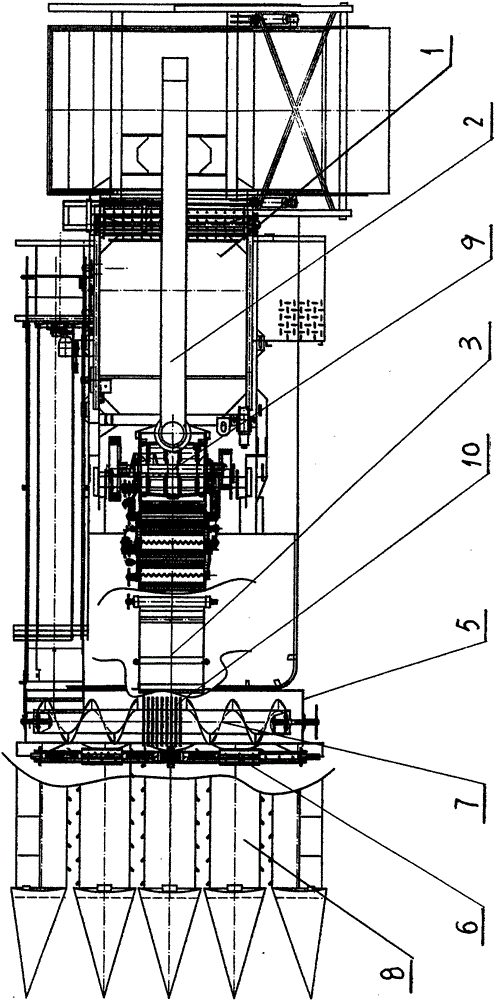

[0010] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. The corn harvester equipped with corn stalk harvesting, crushing, recycling and collecting and releasing strip laying devices includes a corn harvester 1, at the rear side lower part of the horizontal stem pulling and ear picking roller harvesting table assembly 8 of the corn harvester 1. At the end, the hob-type straw cutter shaft assembly 6, the straw two-way conveying auger shaft assembly 7, and the straw collection shield 5 are sequentially assembled parallel to each other, and on the middle part of the straw collection shield 5 Open a discharge port, install straw throwing rake teeth 10 on the middle part of the straw two-way conveying auger shaft assembly 7, and at the discharge port in the middle part of the straw collection fender 5, and install the straw throwing rake teeth 10 on the middle part of the corn harvester 1 The straw crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com