Peanut crushed soil seedling device

A peanut crushing and roller technology, which is applied in excavating harvesters, agricultural machinery and implements, applications, etc., can solve the problems of congestion of fruit picking devices, increased power of cleaning devices, and large size of machine bodies, so as to reduce soil content. , The effect of preventing congestion and reducing clods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

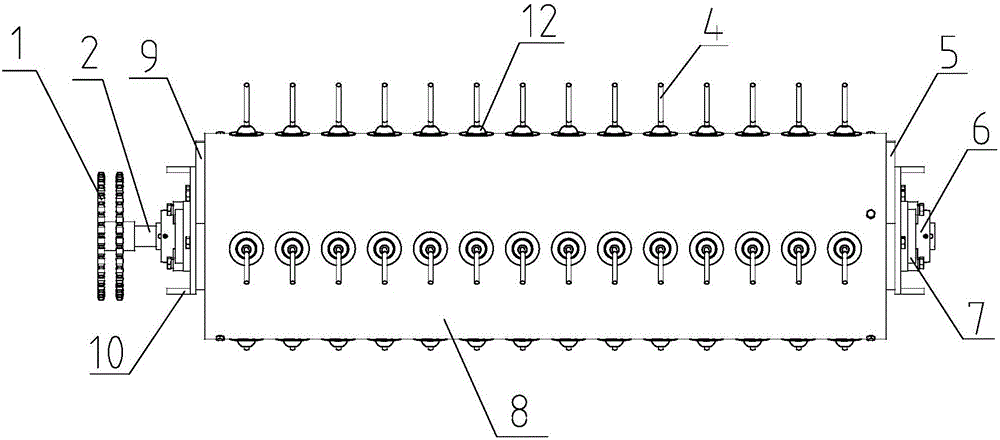

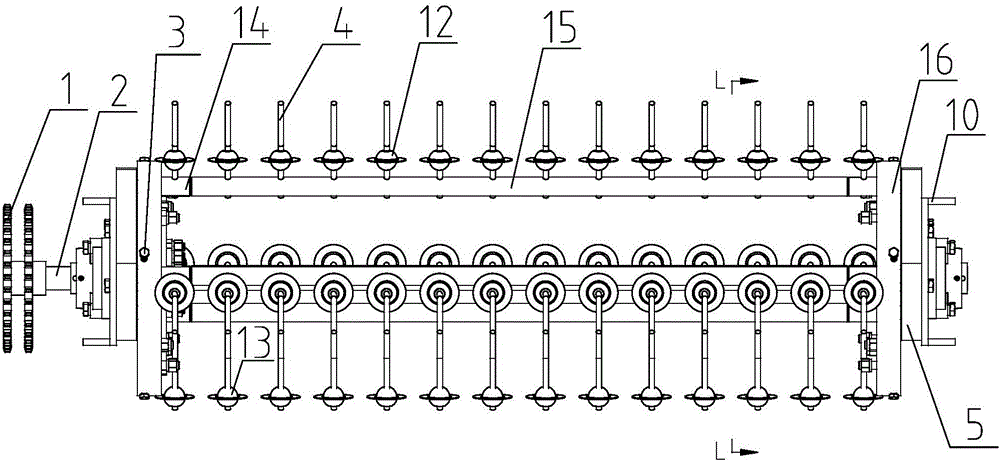

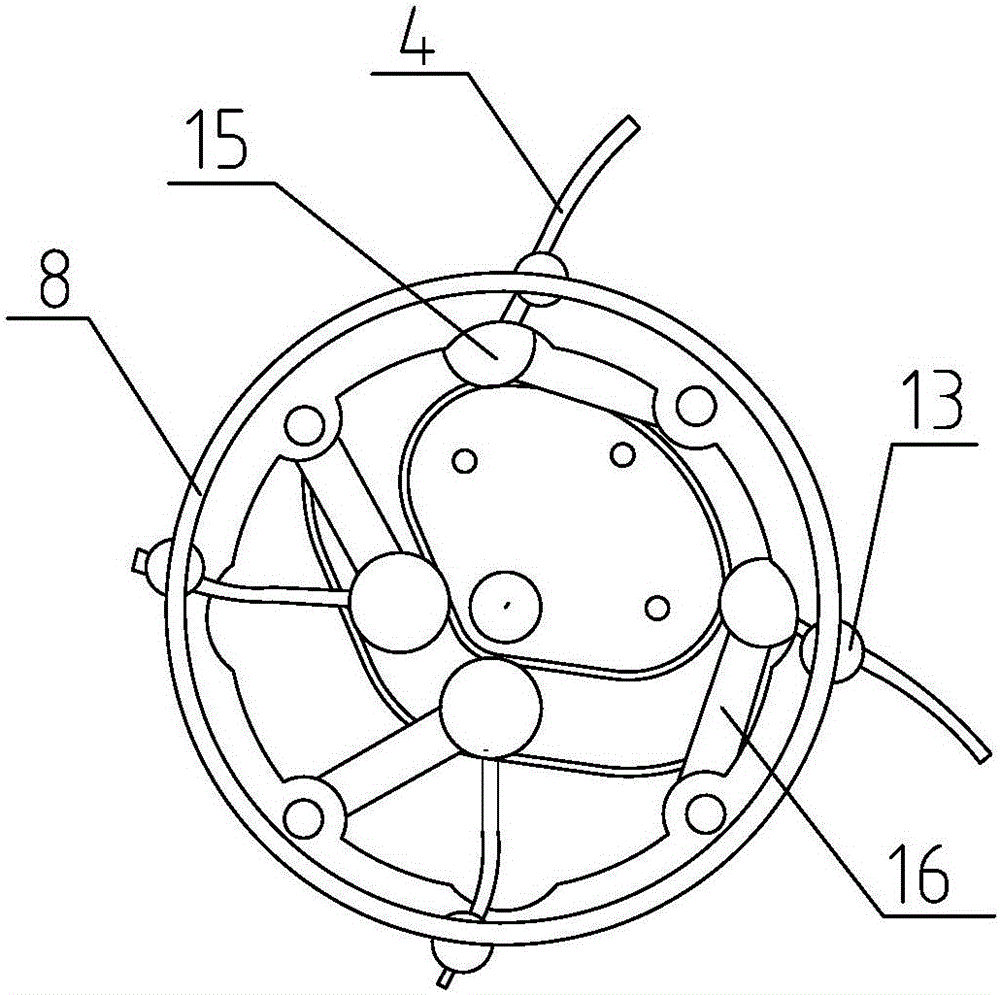

[0025] Peanut crushed seedling device, including driving sprocket 1, rotating main shaft 2, bolt 3, telescopic teeth 4, right track 5, bearing with seat 6, track fixing plate 7, roller 8, left track 9, bearing seat fixing plate 10. Roller fixed plate 11, ball cap 12, through-hole ball 13, gear shaft head 14, gear shaft tube 15, UCP bearing seat 16 and bearing 17. The rotating main shaft 2 is arranged at the center of the roller 8 and is connected with the power device through the driving sprocket 1 . The surface of the roller 8 is provided with a through hole, one end of the telescopic tooth 4 is arranged inside the roller 8 , and the other end of the telescopic tooth 4 is arranged outside the roller 8 through the through hole. Bolts 3 are fixedly connected with the roller 8 around the roller fixing plate 11 . The gear shaft tube 15, the gear shaft head 14, the UCP bearing seat 16 and the bearing 17 form a telescopic gear fixing device, the gear shaft tube 15 and the gear sha...

Embodiment 2

[0029]The difference from Embodiment 1 is that a through-hole ball 13 and a ball protective cap 12 are provided on the outside of the telescopic teeth 4 on the roller 8 . The through hole ball 13 is drilled with a through hole slightly larger than the telescopic tooth 4 diameter, and the inner diameter of the ball protective cap 12 is slightly larger than the outer diameter of the through hole ball 13 . The arc of the arc end of the telescopic tooth 4 is 0.9 rad. The material of the telescopic teeth 4 is Cr-Ni alloy steel wire.

Embodiment 3

[0031] The difference from embodiment 2 is that the number of the pinion rods is 3, and the number of telescopic teeth on each pinion rod is 12. The arc of the arc end of the telescopic tooth 4 is 0.8 rad. The material of the telescopic teeth 4 is piano wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com