Large-scale square banding machine

A baler, large-scale technology, used in packaging, agricultural machinery and implements, applications, etc., can solve problems such as poor working environment, low degree of automation, and low bundle density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

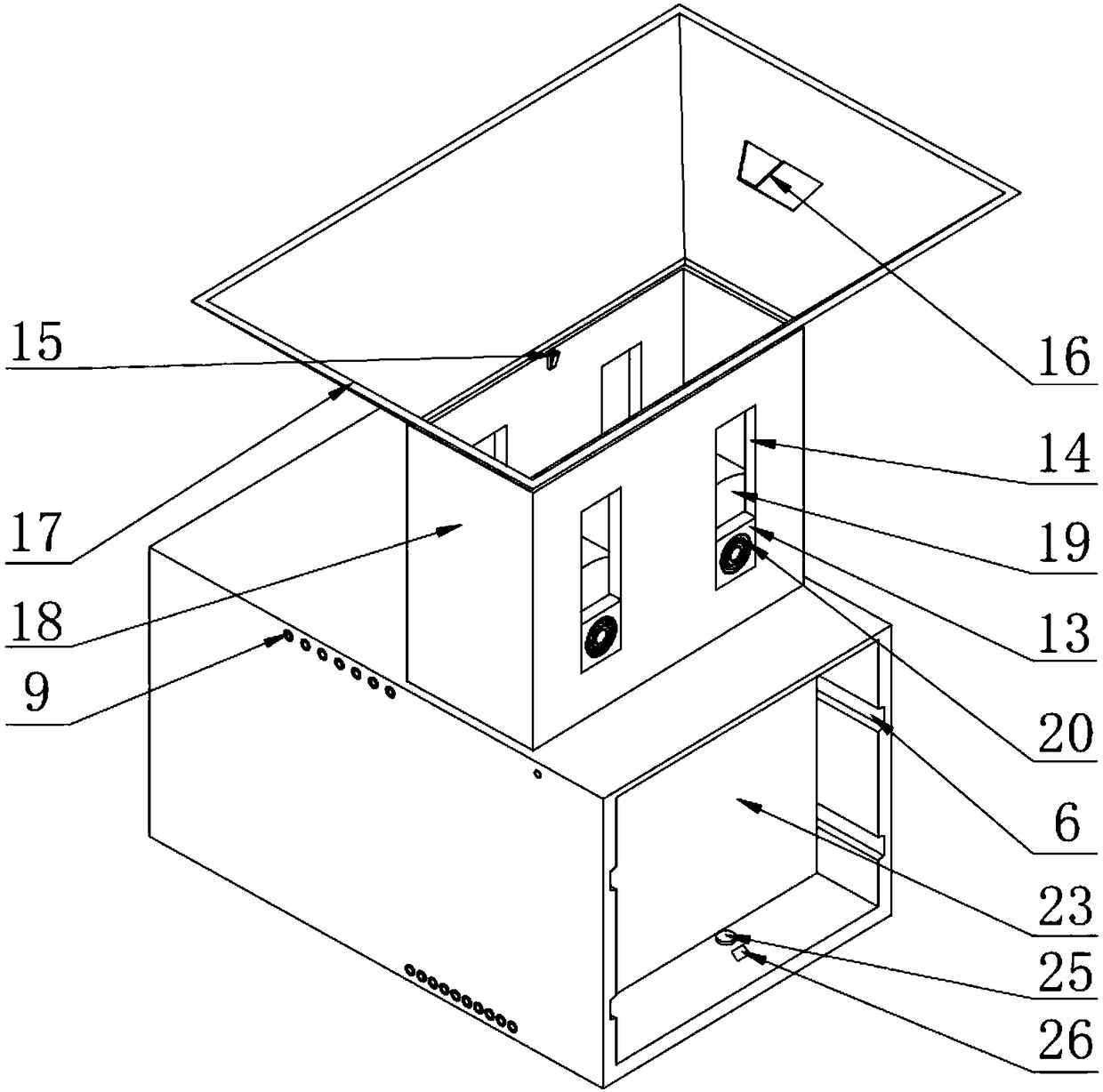

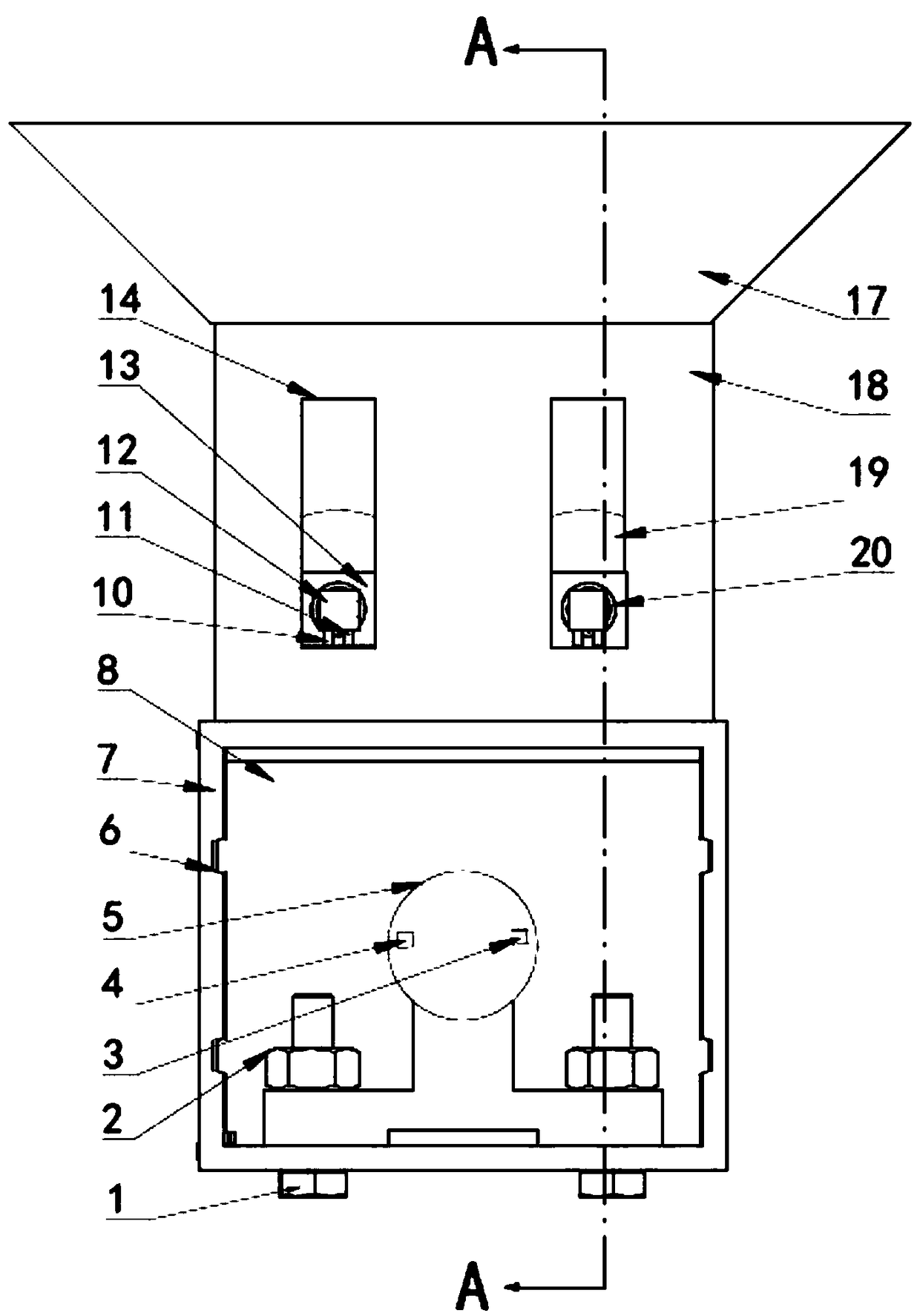

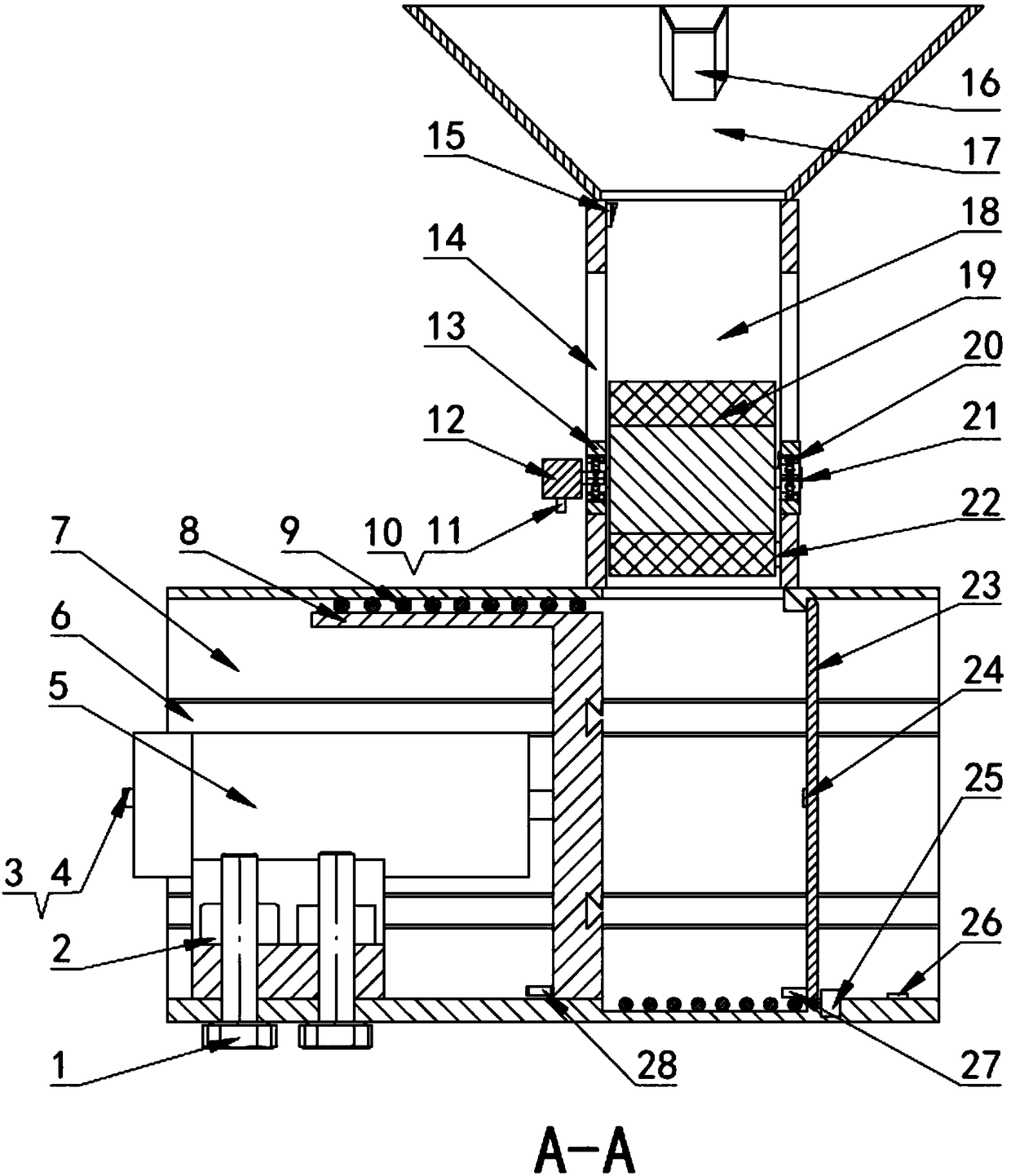

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

[0025]The present invention provides a large-scale square baler, comprising a hollow rectangular compression chamber 7 with both front and rear openings, a rectangular blanking opening is opened in the middle of the upper wall of the compression chamber 7, the blanking opening There is a hollow rectangular pre-compression chamber 18 with upper and lower openings fixed on the upper wall of the compression chamber 7, and a hydraulic cylinder 5 is fixed on the front of the compression chamber 7, and the hydraulic cylinder 5 passes through 4 bolts 1 and 1. 4 nuts 2 are fixed on the lower inner wall of the compression chamber 7, the telescopic rod of the hydraulic cylinder 5 is set back and forth along the horizontal direction, a compression plunger 8 is arranged in the compression chamber 7, and the compression plunger 8 is fixed by a vertical plate and The horizontal plate on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com