Method for recovery plus-negative plate material from waste and old electrode plate

A technology of negative electrode material and positive electrode material, which is applied in the direction of waste collector recycling, battery recycling, recycling technology, etc., and can solve problems such as uneven coating, corner joint waste, powder drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Recycling positive and negative electrode materials from waste and old lithium-ion battery pole pieces by high temperature method

[0024] (a), cleaning the waste and old lithium-ion battery pole pieces (1), removing impurities and sorting out the positive and negative pole pieces;

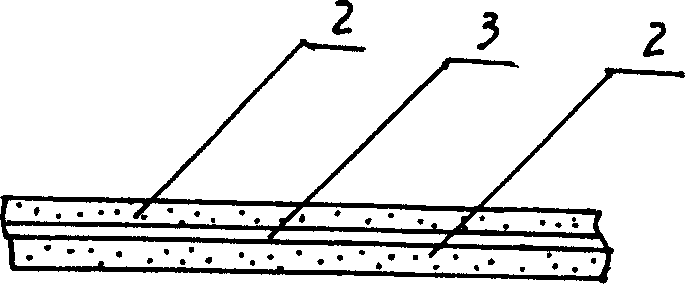

[0025] (b) Place the waste, old positive and negative electrodes in a rotary kiln or pusher kiln respectively, at a temperature of 370-600°C for 3-24 hours, until PVDF is completely decomposed, and the positive and negative electrode materials (2) from the base The material (3) is completely detached and separated, and the positive and negative materials are obtained respectively;

[0026] (c), take off the positive electrode material (2) to detect the components, usually 5-20% lithium cobalt oxide is reduced, and the insufficient lithium element is supplemented to the standard amount;

[0027] (d) Mix the supplementary ingredients and the fallen positive electrode material evenl...

Embodiment 2

[0029] Example 2 The specific gravity method recovers positive and negative electrode materials from waste and old lithium-ion battery pole pieces

[0030] (a), cleaning the waste and old lithium-ion battery pole pieces (1), removing impurities and sorting out the positive and negative pole pieces;

[0031] (b), waste, old positive and negative electrode sheets (1) are respectively placed in a horizontal ball mill, and the grinding balls are resin-wrapped steel balls. , The negative electrode material is completely pulverized and falls off, and the positive and negative electrode materials (2) and the mixture of the substrate (3) fragments, powdery PVDF and conductive agent are respectively obtained;

[0032] (c), remove substrate debris, 200 mesh sieves, the under-sieve is respectively the mixture of positive electrode material, conductive agent and PVDF, the mixture of negative electrode material and PVDF;

[0033] (d) To remove PVDF from the above mixture, place the fallen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com