Thin membrane marking system and controlling method thereof

A marking system and thin-film technology, which is applied in the fields of electrography, manufacturing tools, and electrical recording technology using charge patterns, etc., can solve problems such as productivity problems and parts ID code forgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

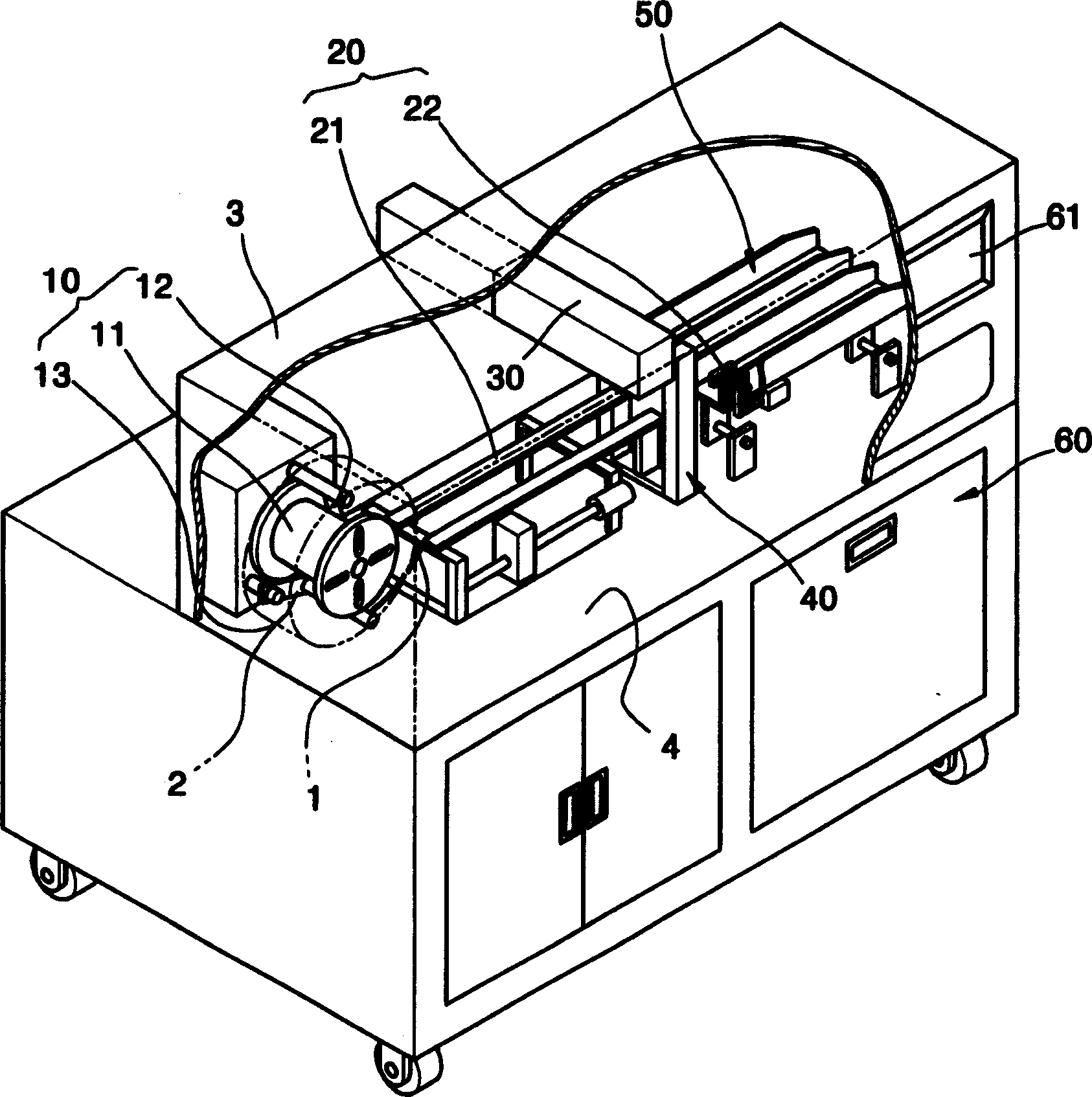

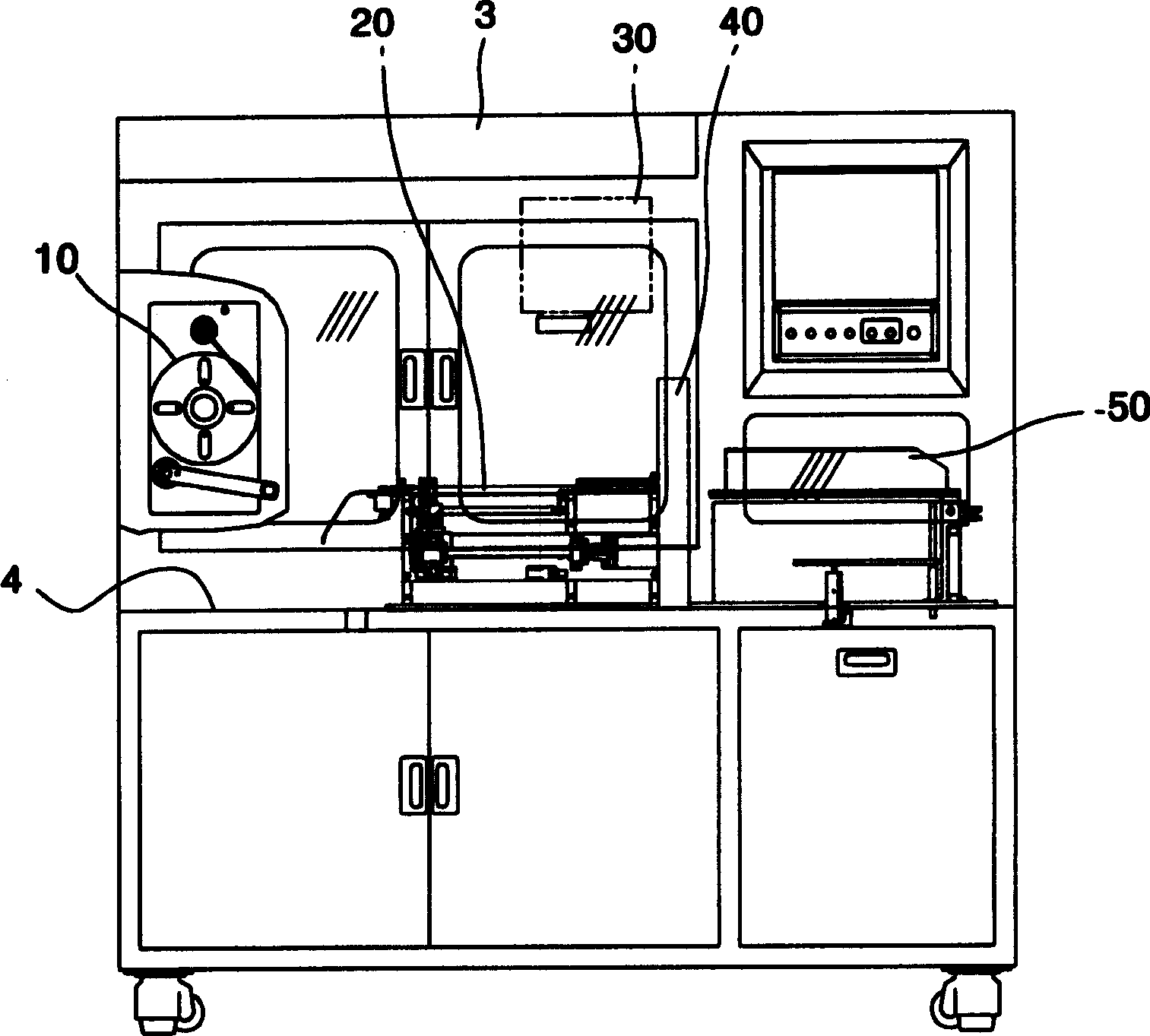

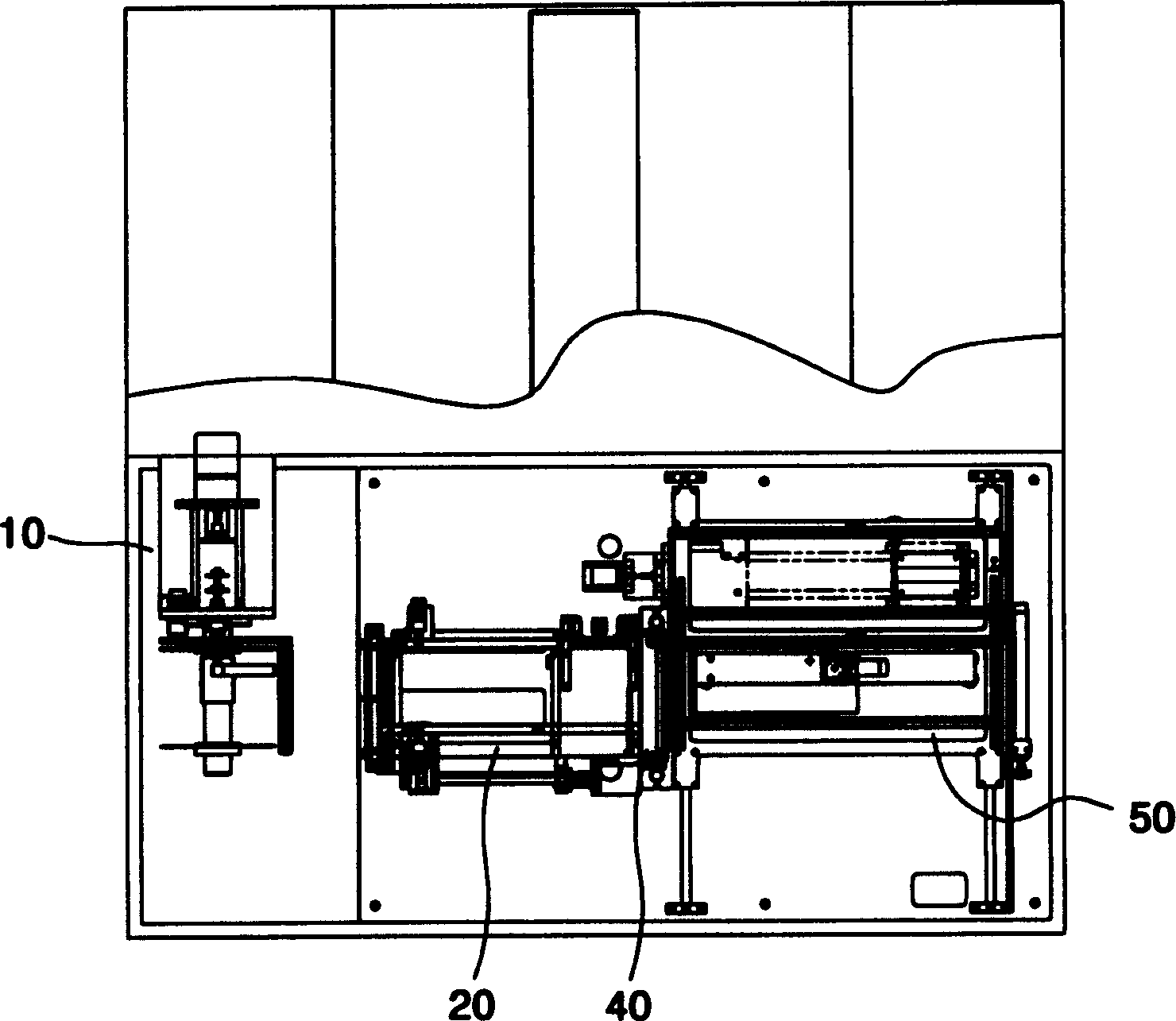

[0040] refer to Figures 1 to 4, shows a film marking system according to a preferred embodiment of the present invention, which uses a laser to mark various characters, numbers or other codes on the adhesive photosensitive film 2 . The film marking system includes: a box body 3, which forms the appearance of the system and protects various units of the system from external substances; a table body 4, which is formed inside the box body 3, and has a predetermined height Loading unit 10; Transport unit 20; Laser module 30; Cutting unit 40; Stacking unit 50; body 4.

[0041] The loading unit 10 is a device for loading and unwinding the film roll 2 to continuously supply the film 1 wound on the film roll 2 to form a roll. refer to Figures 5 to 8 , the loading unit 10 includes: a reel 11 , a material induction plate 12 and a film tension regulator 13 .

[0042] The reel 11 is engaged with the center of the film roll 2 for loading and supporting the film roll 2 which is rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com