Chinese style efficient flue-cured tobacco atomizing agent and application method thereof

An application method and atomizer technology, applied in the application, tobacco, tobacco processing and other directions, can solve the problems of poor consumer experience, inability to improve the sensory quality of heat-not-burn tobacco products, etc., and achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

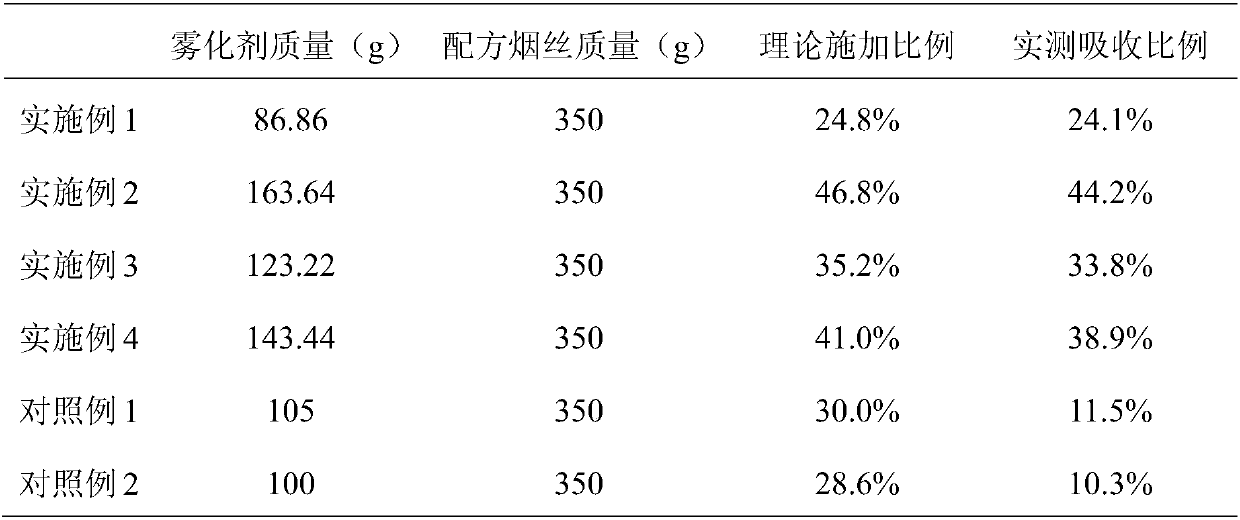

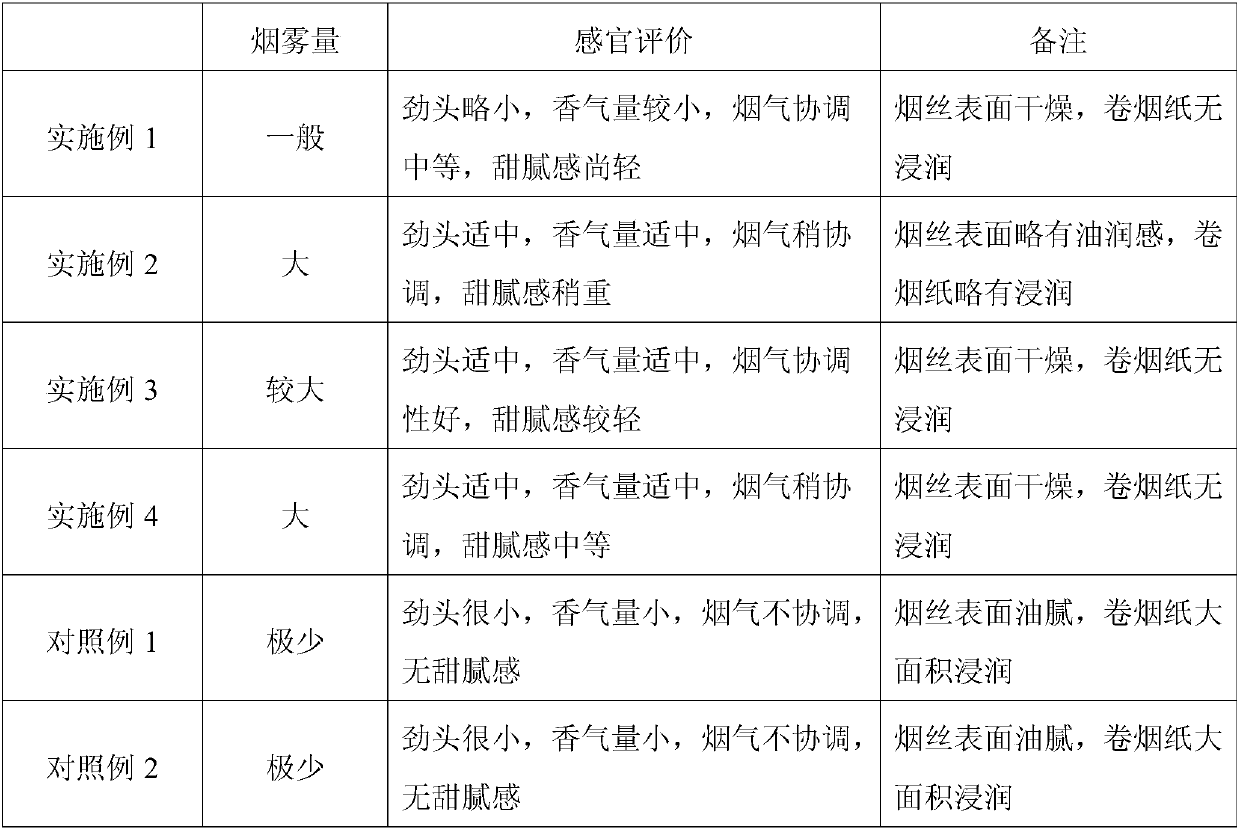

Embodiment 1

[0028] Weigh 2 g of glycerin, 20 g of propylene glycol, 60 g of dipropylene glycol, 4 g of sorbitol, and 0.86 g of geraniol, and mix them uniformly by ultrasonic vibration to obtain the atomizer 1.

[0029] Place 350 g of cut tobacco with the formula in a vacuum freeze dryer, and perform vacuum freezing treatment for 1 hour at a temperature of -10° C. and a vacuum degree of 40 Pa. When the vacuum is released, the atomizing agent 1 is quickly sprayed on the surface of the formula shredded tobacco from the pressure relief tank. After the shredded tobacco fully absorbs the atomizer 1, the shredded tobacco is taken out and placed in a constant temperature and humidity box. Equilibrate at a temperature of 20° C. and a humidity of 50% for 2 hours.

Embodiment 2

[0031] Weigh 2 g of glycerin, 40 g of propylene glycol, 100 g of dipropylene glycol, 20 g of sorbitol, and 1.64 g of geraniol, mix them uniformly by ultrasonic vibration, and obtain the atomizer 2.

[0032] 350 g of cut tobacco with the formula was placed in a vacuum freeze dryer, and subjected to vacuum freezing treatment at a temperature of -30° C. and a vacuum degree of 10 Pa for 5 hours. When the vacuum is released, the atomizer 2 is quickly sprayed on the surface of the formula shredded tobacco from the pressure relief tank. After the shredded tobacco has fully absorbed the atomizer 2, the shredded tobacco is taken out and placed in a constant temperature and humidity chamber. Equilibrate at a temperature of 30° C. and a humidity of 70% for 24 hours.

Embodiment 3

[0034] Weigh 2 g of glycerin, 30 g of propylene glycol, 80 g of dipropylene glycol, 10 g of sorbitol, and 1.22 g of geraniol, mix them uniformly by ultrasonic vibration, and obtain the atomizer 3.

[0035] 350 g of cut tobacco with the formula was placed in a vacuum freeze dryer, and subjected to vacuum freezing treatment for 3 hours at a temperature of -20° C. and a vacuum degree of 20 Pa. When the vacuum is released, the atomizer 3 is quickly sprayed on the surface of the formula shredded tobacco from the pressure relief tank. After the shredded tobacco fully absorbs the atomizing agent 3, the shredded tobacco is taken out and placed in a constant temperature and humidity box. Equilibrate at a temperature of 25° C. and a humidity of 60% for 10 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com