Modified titanaugite for high heat-resistance and anti-aging butadiene-acrylonitrile rubber cable material and preparation method thereof

A nitrile rubber, anti-aging technology, applied in the direction of rubber insulators, organic insulators, etc., can solve the problems of limited application range, unable to meet the multi-functional filler, low filling function, etc., to improve compatibility, improve application range and use Longevity and effect of improving filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

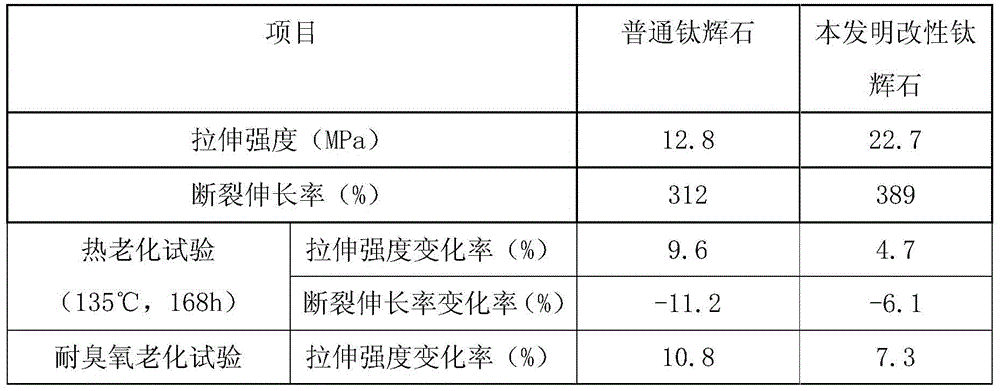

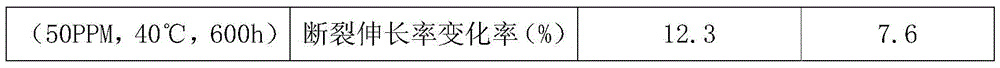

[0012] A modified titanium pyroxene for high heat-resistant and anti-aging nitrile rubber cable material, which is made of the following weight (kg) raw materials: titanium pyroxene 36, raw ore red mud 28, sludge dry powder 20, polyphenylquinoxine Phyloline 24, hexachlorocyclotriphosphazene 18, epoxy rice bran octyl oleate 13, triethanolamine oleate 4, high molecular weight polybutene 6, vanadium acetylacetonate 3, hydrogenated rosin pentaerythritol ester 8, hydroxyaluminum oxalate 4, N- Nitrosodimethylamine 1.5, 4,4'-diaminodiphenylmethane 1, composite additive 6;

[0013] The preparation method of described compound auxiliary agent is as follows: a, get the raw material of following weight (kg): diethyl glutarate 8, oxaloacetate 3, discarded molding sand 15, organosilicon microsphere 6, neodymium neodecanoate 2, Cocamidopropyl amine oxide 3, ochre powder 6, cellulose acetate butyrate 4, lanolin magnesium soap 5, cobalt boroacylate 4, N-ethyl-o, p-toluenesulfonamide 2; b, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com