Hydroxy aluminium oxalate, and its preparing method and hydroxy aluminium oxalate as fire retardant

A technology of hydroxyaluminum oxalate and hydroxyoxalic acid, which is applied in the preparation of carboxylate, organic chemistry, etc., can solve the problems of complex structure of rotating bed equipment, high viscosity of hydrated alumina, inconvenient maintenance and disassembly, etc., and achieve simple structure and low weight loss temperature High and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 45 grams of industrial sodium hydroxide to 100 ml of tap water, heat, add 65 grams of industrial aluminum hydroxide after the solution boils, boil for 30 minutes, then add tap water to 800 ml, filter, and remove impurities to obtain partial aluminum Sodium acid solution, its concentration is about 1.0mol / L. Put this sodium metaaluminate solution in a stirred reaction kettle, at 20°C, let in the carbon dioxide gas from the decompressed steel cylinder, and start the agitator at the same time, when the pH value of the solution becomes 10.5, the carbonization and decomposition will end reaction. The resulting slurry is filtered and washed to obtain an aluminum hydroxide filter cake. Then stir the filter cake with deionized water, add solid oxalic acid, make a suspension according to the molar ratio of aluminum hydroxide and oxalic acid 1:0.7, put it in an autoclave for modification treatment, heat it to a temperature of 160°C, and 45 minutes at constant temperature. ...

Embodiment 2

[0042] Except that following operating conditions change, all the other are the same as embodiment 1. 108 grams of sodium hydroxide are added to 150 milliliters of tap water, and the aluminum hydroxide of 158 grams is added after being heated to solution boiling. Continue heating, boil for 30 minutes, and obtain a sodium metaaluminate solution with a concentration of about 2.5mol / L after filtering. It is carbonized and decomposed at 60°C, and the pH value of the end point of carbonization is 11.5. During the modification treatment, the constant temperature was 180° C., the time was 30 minutes, and the molar ratio of oxalic acid to aluminum hydroxide was 1. The slurry obtained after modification is directly filtered, washed, and the filter cake is dried without adding a crystal form control agent to obtain a hydroxyaluminum oxalate product.

Embodiment 3

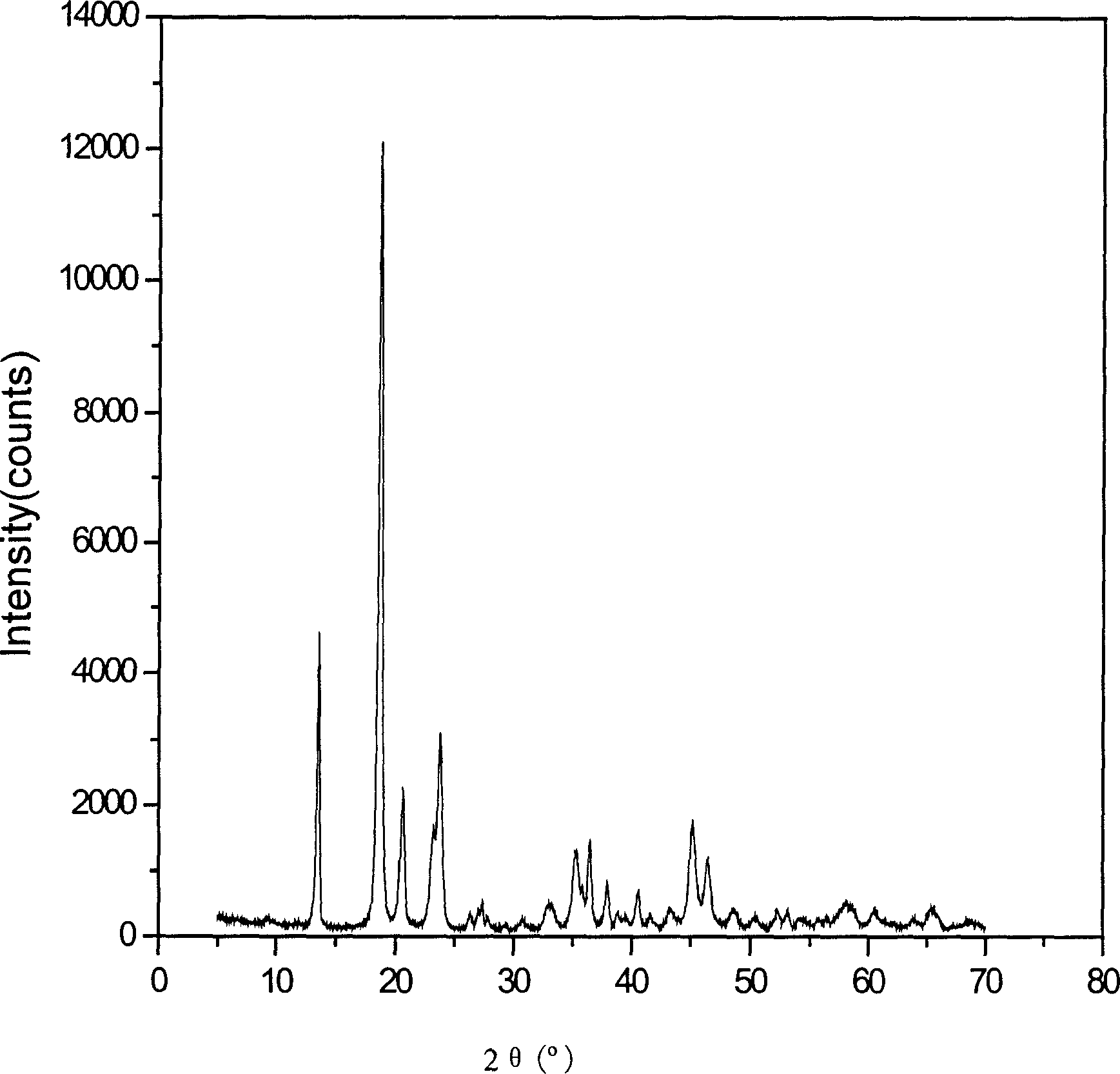

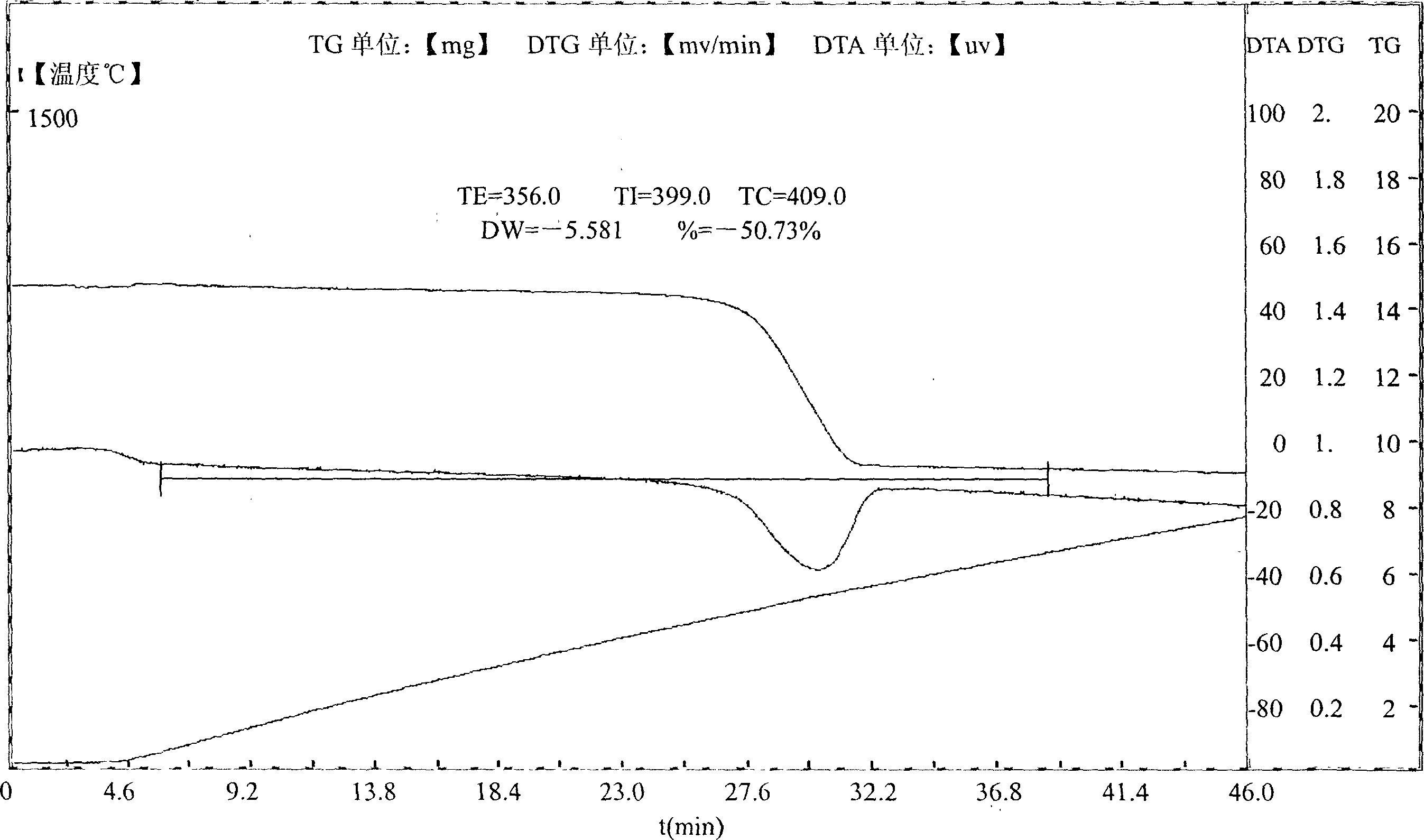

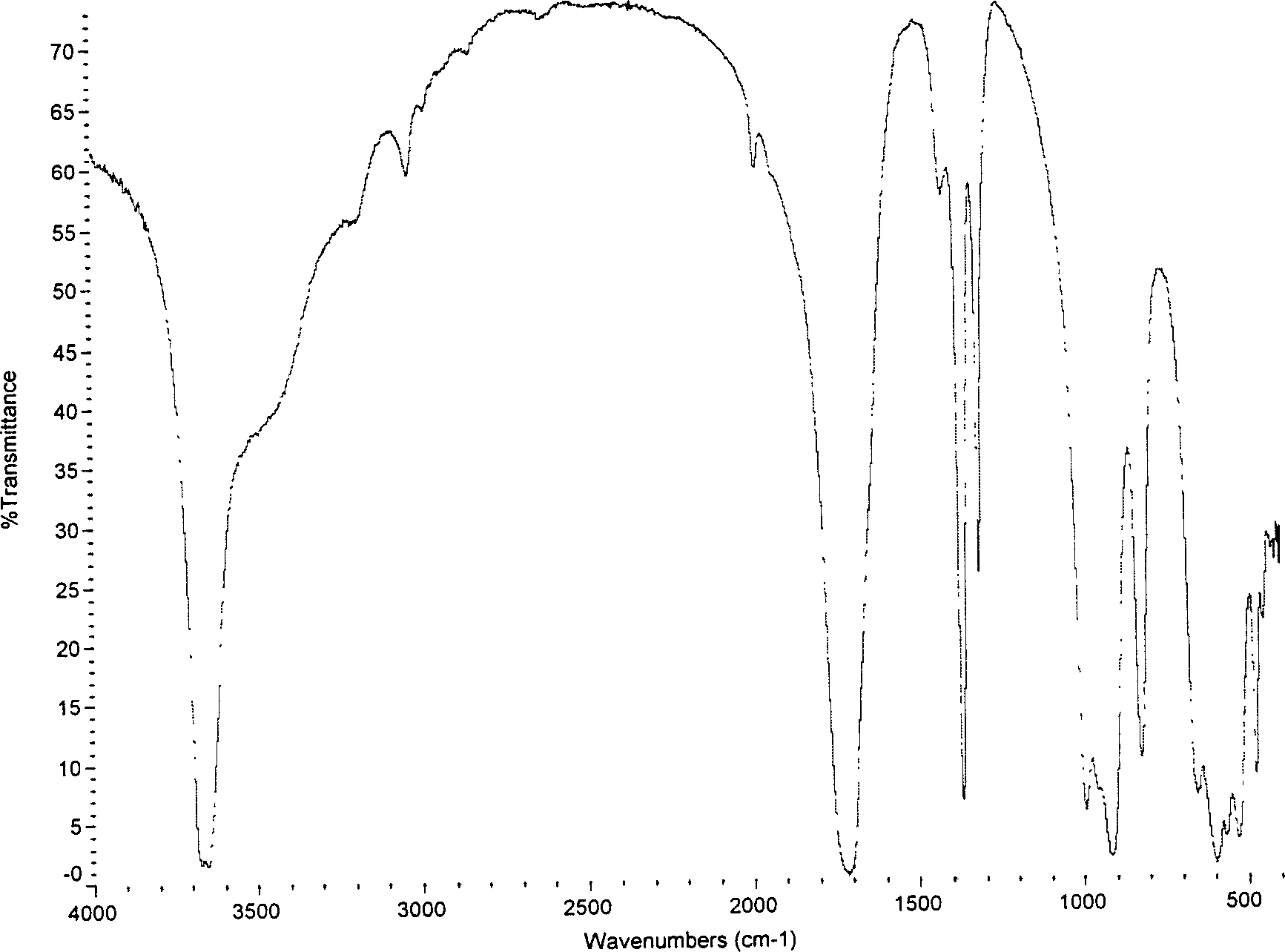

[0044] Except that following operating conditions change, all the other are the same as embodiment 1. During the modification process, the temperature was maintained at 170° C. for 60 minutes. The prepared modified slurry is directly filtered, washed and the filter cake is dried without adding a crystal form control agent to obtain a chain-like spherical hydroxyaluminum oxalate product. Its TEM picture is shown in Figure 5 , the extrapolated initial weight loss temperature is 356°C, the peak temperature is 399°C, the weight loss rate before 500°C is 50.73%, and its bulk density is 0.51g / cm 3 , the compact density is 0.87g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com