Preparation method of porous alpha-alumina membrane

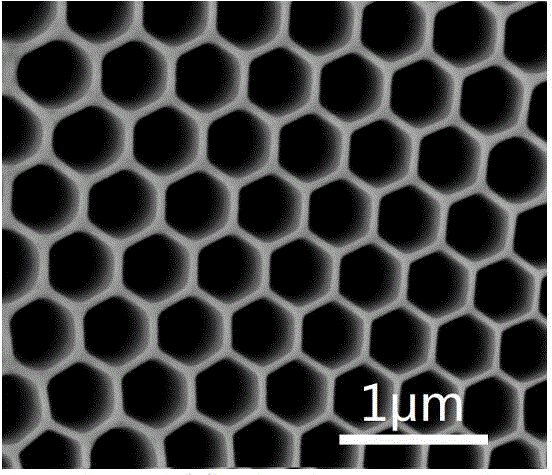

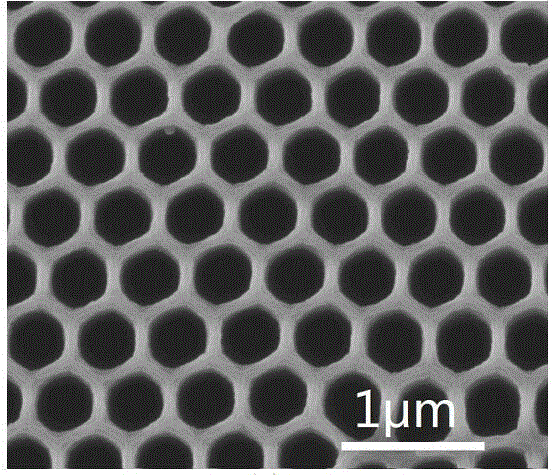

A technology of aluminum oxide film and anodized aluminum, which is applied in the field of nano-synthesis and micro-nano, can solve the problems of periodic hexagonal close-packed structure damage, membrane curling, cracking, etc., and achieve orderly arrangement, smooth membrane and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

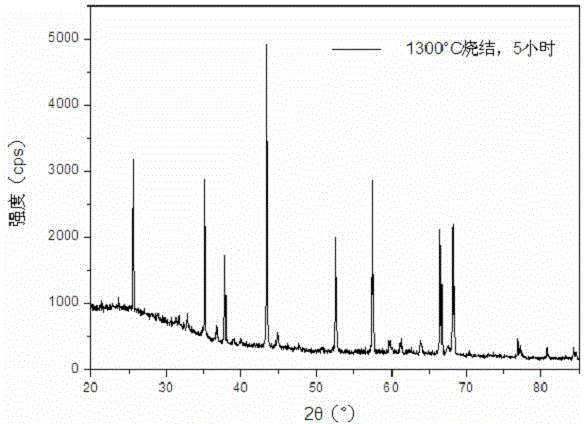

Examples

Embodiment 1

[0031] A method for preparing a porous α-alumina membrane, comprising the steps of:

[0032] (1) Use conventional techniques to anneal and electropolish pretreatment of high-purity aluminum foil with a purity of more than 99.99%; put it in a muffle furnace for annealing to eliminate the internal stress of the aluminum foil; Ultrasonic cleaning in medium to remove surface grease; then put the cleaned aluminum foil into perchloric acid absolute ethanol mixture for electropolishing at a constant voltage of 21V;

[0033] (2) Use the aluminum foil pretreated in step (1) as the anode, and graphite as the cathode, and perform two-step anodization in a mixed solution of phosphoric acid and aluminum oxalate to obtain an aluminum-based porous anodized aluminum film; two-step anodization The mass ratio of phosphoric acid in the electrolyte used is 0.01-5%, the concentration of aluminum oxalate is 0.005-0.05 mol / liter, the anodic oxidation voltage is 180V-250V, the electrolyte temperature...

Embodiment 2

[0040] A method for preparing a porous α-alumina membrane, comprising the steps of:

[0041] (1) Put high-purity aluminum foil (above 99.99% purity) into a muffle furnace for annealing at 450°C for 6 hours to eliminate the internal stress of the aluminum foil, and ultrasonically clean the annealed aluminum foil for 15 minutes in acetone and absolute ethanol solutions respectively, To remove surface grease; then put the cleaned aluminum foil into a perchloric acid absolute ethanol mixture with a volume ratio of 1:4 for electropolishing at a constant voltage of 21V;

[0042] (2) Use the aluminum foil pretreated in step (1) as the anode, and graphite as the cathode, and perform two-step anodization in a mixed solution of 1% phosphoric acid and 0.01 mol / liter aluminum oxalate by mass ratio; the anodic oxidation voltage is 210V , the electrolyte temperature is 5°C, and the anodic oxidation time is 8 hours;

[0043] (3) The aluminum-based porous anodic aluminum oxide membrane prepare...

Embodiment 3

[0049] This embodiment is implemented under the following technical requirement conditions:

[0050] Other conditions are the same as in Example 2 in this example. The aluminum foil pretreated in step (1) was used as the anode, graphite was used as the cathode, and two-step anodic oxidation was carried out in a mixed solution with a mass ratio of 0.03% phosphoric acid and 0.005 mol / L aluminum oxalate. The anodizing voltage was 185V, the electrolyte temperature was 0°C, and the anodizing time was 10 hours. By implementing the above method, a porous α-alumina inorganic membrane with a periodic hexagonal close-packed through-hole structure is finally prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com