Self-protection flux-cored wire applicable for pipeline steel welding

A flux-cored wire, self-protection technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of many pores and spatter, large smoke, poor low temperature toughness, etc., to reduce spatter phenomenon, cover Uniform, high temperature impact toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

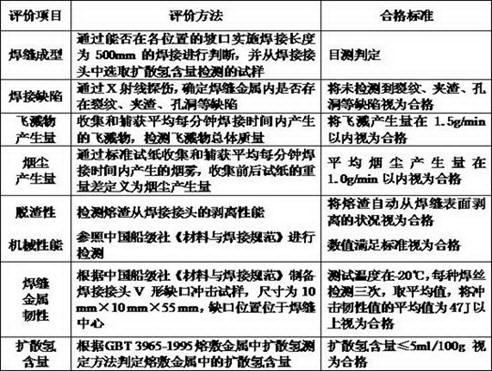

Image

Examples

Embodiment Construction

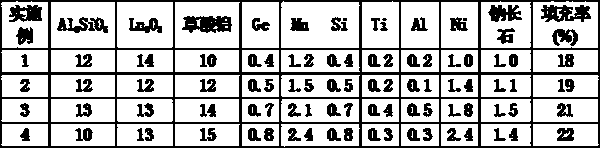

[0015] According to the specific welding pipeline steel, the flux core powder is prepared according to the components in Table 1, and after drying at 120-300 °C, it is mixed evenly and added to the cold-rolled steel strip at a filling rate of 18-22%. In the welding wire for the outer skin.

[0016] Table 1 Flux cored wire components and mass percentage (%)

[0017]

[0018] The test materials are X60, X65, X70, and the size of the test plate is 300×150×20mm. According to the "Materials and Welding Specifications" of China Classification Society, the Y-shaped groove is processed, and the multi-layer and multi-pass welding method is adopted. After the front side is surfacing and the back is cleaned, there is one welding, and the non-pulse constant voltage power supply is used for DC positive connection. The V-notch impact specimens of welded joints were prepared according to the "Code for Materials and Welding" of China Classification Society. The size of the impact s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com